Table of Contents

Ukuphonononga iiNzuzo zokuSebenzisa oomatshini bokuPakisha iGubu elikwisantya esiphezulu socingo lwe-Welding

Indlela yokukhetha umatshini wokuPakisha iGubu eliPhakamileyo eliLungileyo kwi-Welding Wire

Enye into ebalulekileyo ekufuneka iqwalaselwe sisantya somatshini. Imishini yokupakisha i-drum yesantya esiphezulu yenzelwe ukusebenza ngokukhawuleza nangokufanelekileyo, ngoko ke kubalulekile ukukhetha umatshini onokuthi uhambisane neemfuno zomgca wakho wokuvelisa. Khangela umatshini onesantya esiphezulu sokupakisha kwaye unokusingatha umsebenzi oqhubekayo ngaphandle kwexesha lokuphumla.

Ngaphezu komthamo kunye nesantya, kubalulekile ukuqwalasela ukuqina kunye nokuthembeka komatshini. Oomatshini bokupakisha idrum ngesantya esiphezulu lutyalo-mali olubalulekileyo, ngoko ke kubalulekile ukukhetha umatshini owakhiwe ukuba uhlale. Khangela umatshini owenziwe kwizinto ezikumgangatho ophezulu kwaye unegama lokuthembeka. Oku kuya kuqinisekisa ukuba umatshini wakho unokumelana nobunzima bokusetyenziswa kwemihla ngemihla kwaye unikeze ukusebenza okuhambelanayo ngokuhamba kwexesha.

Xa ukhetha umatshini wokupakisha igubu lesantya esiphezulu kwi-welding wire, kukwabalulekile ukuqwalasela iimpawu kunye nobuchule bomatshini. Khangela umatshini onikezela ngeempawu eziphambili ezifana nokulayishwa kwegubu ngokuzenzekelayo kunye nokukhulula, isantya esilungelelanisiweyo sokupakisha, kunye nolawulo olulula ukuyisebenzisa. Ezi mpawu zinokunceda ukulungelelanisa inkqubo yokupakisha kunye nokuphucula ukusebenza kakuhle ekusebenzeni kwakho.

Kukwabalulekile ukuqwalasela unyawo lomatshini kunye nendlela oya kungena ngayo kwindawo yakho yokuvelisa. Imishini yokupakisha i-drum ye-speed-speed iza ngobukhulu obuhlukeneyo kunye nokucwangciswa, ngoko kubalulekile ukukhetha umatshini oya kuhambelana kakuhle kwindawo yakho. Qwalasela ukucwangciswa komgca wakho wokuvelisa kunye nesithuba esikhoyo kumatshini ukuqinisekisa inkqubo yokufakela egudileyo.

Ekuqukumbeleni, ukukhetha umatshini wokupakisha idrum ochanekileyo wesantya esiphezulu kwi-welding wire sisigqibo esibalulekileyo esinokuba nempembelelo enkulu ukusebenza kakuhle kunye nemveliso yokusebenza kwakho. Qwalasela izinto ezifana nomthamo, isantya, ukuqina, iimpawu, kunye noshicilelo lweenyawo xa ukhetha umatshini ohlangabezana neemfuno zakho ezithile. Ngokukhetha umatshini okumgangatho ophezulu owakhelwe ukuhlala kwaye unikezela ngeempawu eziphambili, unokuphucula inkqubo yokupakisha kunye nokwandisa imveliso ekusebenzeni kwakho kwe-welding.

In addition to the benefits mentioned above, high-speed drum packing machines also offer improved safety features. Manual packaging of welding wire can be hazardous, as workers are exposed to sharp edges and heavy materials. By using a high-speed drum packing machine, businesses can reduce the risk of injuries and create a safer working environment for their employees.

Overall, the benefits of using a high-speed drum packing machine for welding wire are clear. From increased productivity and efficiency to cost savings and improved safety, these machines offer a range of advantages for businesses in the manufacturing industry. By investing in this technology, companies can streamline their packaging process, increase their production output, and ultimately improve their bottom line.

How to Choose the Right High-Speed Drum Packing Machine for Welding Wire

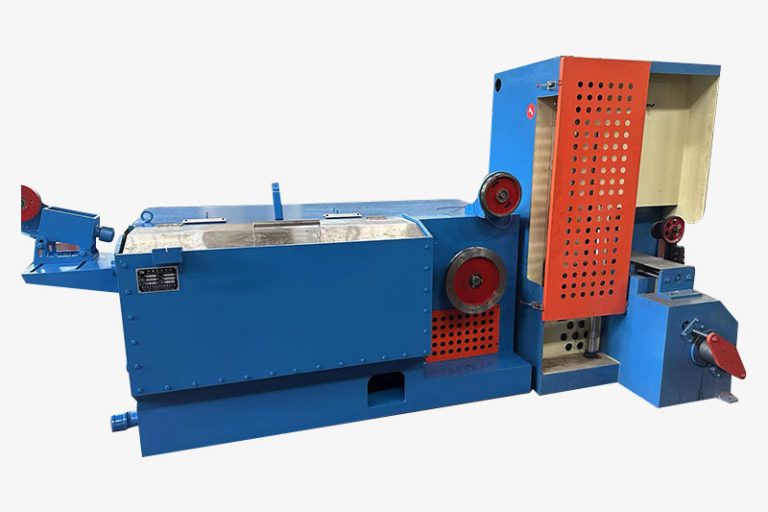

When it comes to packaging welding wire, efficiency and speed are key factors to consider. High-speed Welding Wire Drum Packer machines are designed to meet the demands of the welding industry by providing fast and reliable packaging solutions. These machines are capable of handling large volumes of welding wire and can significantly increase productivity in a manufacturing setting.

When choosing the right high-speed drum packing machine for welding wire, there are several factors to consider. The first consideration is the capacity of the machine. It is important to choose a machine that can handle the volume of welding wire that your operation requires. Look for a machine that has a high capacity and can accommodate different sizes of drums to meet your specific needs.

Another important factor to consider is the speed of the machine. High-speed drum packing machines are designed to work quickly and efficiently, so it is important to choose a machine that can keep up with the demands of your production line. Look for a machine that has a high packing speed and can handle continuous operation without downtime.

In addition to capacity and speed, it is also important to consider the durability and reliability of the machine. High-speed drum packing machines are a significant investment, so it is important to choose a machine that is built to last. Look for a machine that is made from high-quality materials and has a reputation for reliability. This will ensure that your machine can withstand the rigors of daily use and provide consistent performance over time.

When choosing a high-speed drum packing machine for welding wire, it is also important to consider the features and capabilities of the machine. Look for a machine that offers advanced features such as automatic drum loading and unloading, adjustable packing speed, and easy-to-use controls. These features can help streamline the packaging process and improve efficiency in your operation.

It is also important to consider the footprint of the machine and how it will fit into your production space. High-speed drum packing machines come in a variety of sizes and configurations, so it is important to choose a machine that will fit comfortably in your facility. Consider the layout of your production line and the space available for the machine to ensure a smooth installation process.

In conclusion, choosing the right high-speed drum packing machine for welding wire is an important decision that can have a significant impact on the efficiency and productivity of your operation. Consider factors such as capacity, speed, durability, features, and footprint when selecting a machine that meets your specific needs. By choosing a high-quality machine that is built to last and offers advanced features, you can improve the packaging process and increase productivity in your welding operation.