Table of Contents

Ukulunga kokuSebenzisa i-Speed Speed Copper Coating Production Line ye-CO2 Welding Wire

Indlela yokuphucula ukusebenza kunye nomgangatho kwi-CO2 Welding Wire Production kunye ne-Speed High Copper Coating Line

Enye yeenzuzo eziphambili zomgca wokuvelisa i-copper high-speed yikhono layo lokugubungela iingcingo ezininzi ngaxeshanye. Oku akukhawulezisi nje inkqubo yokuvelisa, kodwa kwakhona kuqinisekisa ukuqina kokwambathisa okuhambelanayo kuzo zonke iingcingo. Oku kubalulekile ekugcineni umgangatho kunye nokusebenza kwemveliso yokugqibela, njengoko ukuhluka kobunzima bokugquma kunokukhokelela kwimiba efana ne-conductivity engafanelekanga okanye ukumelana nokugqwala. uluhlu olubanzi lweedamitha zocingo. Oku bhetyebhetye kuvumela abavelisi ukuba bavelise ubungakanani obuhlukeneyo bengcingo ngaphandle kwesidingo sokuphinda kusetyenziswe ixabiso okanye ixesha lokuphumla. Oku kunokuba luncedo ngokukhethekileyo kwiinkampani ezivelisa uluhlu lweemveliso ze-welding wire, njengoko zivumela ukuba zitshintshe ngokukhawuleza phakathi kobukhulu obuhlukeneyo ukuhlangabezana neemfuno zabathengi.

Ngaphezu kokuphucula ukusebenza kakuhle kunye nomgangatho, umgca wokuvelisa i-copper high-speed copper can ikwanceda ekunciphiseni inkunkuma nokuphucula uzinzo. Ngokuzenzekelayo inkqubo yokugquma, abavelisi banokunciphisa inani lobhedu olusetyenzisiweyo, kunye nokunciphisa umngcipheko wokuchithwa okanye ezinye iingozi zendalo. Oku akuncedi kuphela umgca ophantsi, kodwa kunceda ukukhusela indalo kwizizukulwana ezizayo.

Ngokupheleleyo, utyalo-mali kumgca wokuvelisa i-copper high-speed copper unokuba nempembelelo enkulu ekusebenzeni kunye nomgangatho we-CO2 welding wire production. Ngokuzenzekelayo inkqubo yokugquma, abavelisi banokwandisa imveliso, banciphise inkunkuma, kwaye baphucule ukuhambelana kweemveliso zabo. Oku kunokukhokelela ekwanelisekeni okuphezulu kwabathengi, ukunyuka kwenzuzo, kunye nokuncintisana okunamandla kwimarike.Ekuqukunjelweni, umgca wokuvelisa ubhedu olukhawulezayo lutyalo-mali oluxabisekileyo kuyo nayiphi na inkampani ejonge ukuphucula ukusebenza kakuhle kunye nomgangatho kwimveliso ye-CO2 welding wire. Ngokuzenzekelayo inkqubo yokugquma, abavelisi banokuhlengahlengisa imisebenzi yabo, banciphise inkunkuma, kwaye baqinisekise imveliso engaguqukiyo. Oku kunokukhokelela ekwanelisekeni komthengi okwandisiweyo, inzuzo ephezulu, kunye nesikhundla esinamandla kwimarike

In the world of manufacturing, efficiency and quality are two key factors that can make or break a business. This is especially true in industries such as CO2 welding wire production, where precision and consistency are essential. One way to improve both efficiency and quality in CO2 welding wire production is by investing in a high-speed copper coating production line.

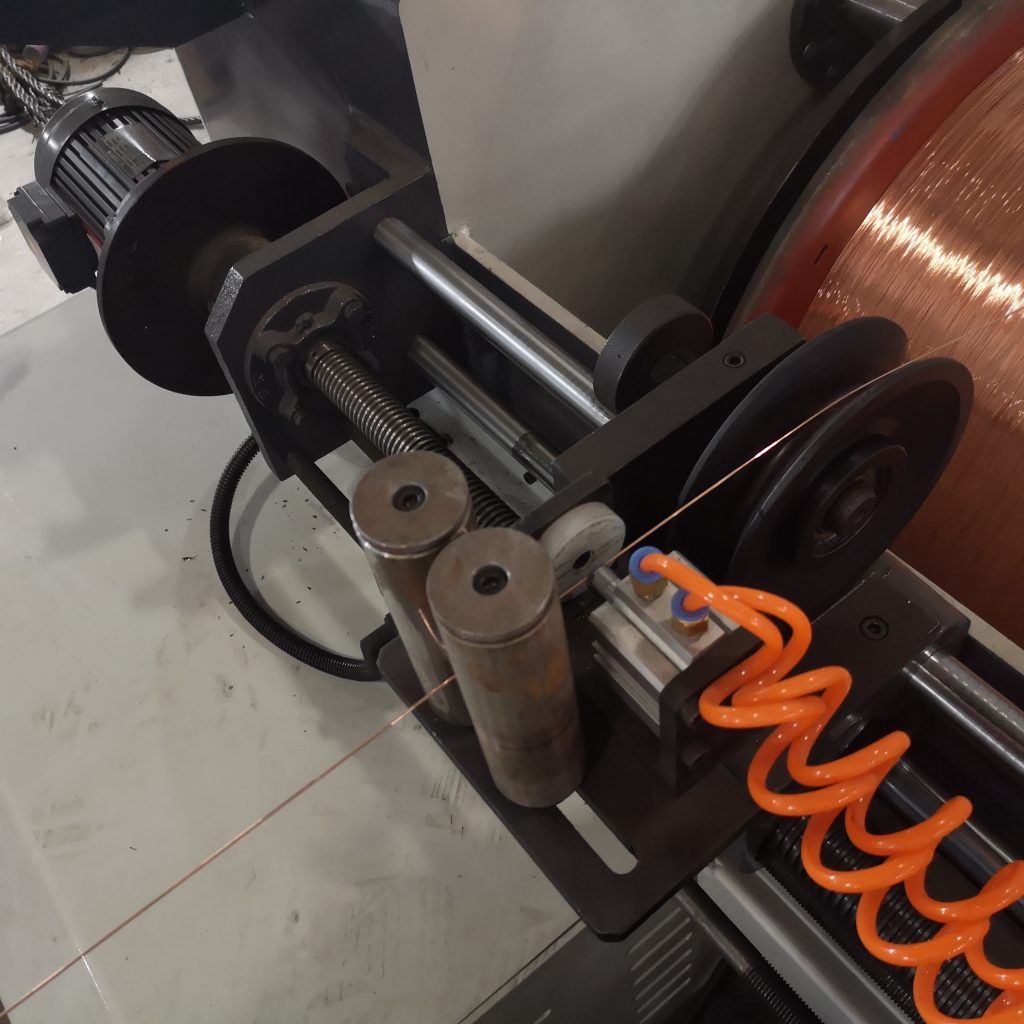

Copper coating is a crucial step in the production of CO2 welding wire, as it helps to improve the conductivity and corrosion resistance of the wire. Traditionally, copper coating has been a time-consuming and labor-intensive process, requiring skilled operators to manually apply the coating to each individual wire. However, with a high-speed copper coating production line, this process can be automated, significantly increasing efficiency and reducing the risk of human error.

One of the key benefits of a high-speed copper coating production line is its ability to coat multiple wires simultaneously. This not only speeds up the production process, but also ensures a more consistent coating thickness across all wires. This is essential for maintaining the quality and performance of the final product, as variations in coating thickness can lead to issues such as poor conductivity or corrosion resistance.

Another advantage of a high-speed copper coating production line is its ability to handle a wide range of wire diameters. This flexibility allows manufacturers to produce a variety of wire sizes without the need for costly retooling or downtime. This can be especially beneficial for companies that produce a range of welding wire products, as it allows them to quickly switch between different sizes to meet customer demand.

In addition to improving efficiency and quality, a high-speed copper coating production line can also help to reduce waste and improve sustainability. By automating the coating process, manufacturers can minimize the amount of copper used, as well as reduce the risk of spills or other environmental hazards. This not only benefits the bottom line, but also helps to protect the environment for future generations.

Overall, investing in a high-speed copper coating production line can have a significant impact on the efficiency and quality of CO2 welding wire production. By automating the coating process, manufacturers can increase productivity, reduce waste, and improve the consistency of their products. This can lead to higher customer satisfaction, increased profitability, and a stronger competitive edge in the market.In conclusion, a high-speed copper coating production line is a valuable investment for any company looking to improve efficiency and quality in CO2 welding wire production. By automating the coating process, manufacturers can streamline their operations, reduce waste, and ensure a more consistent product. This can lead to increased customer satisfaction, higher profitability, and a stronger position in the market.