Table of Contents

Indlela yokukhetha iNdlela yokuLungileyo ye-Copper-Coating Line ye-CO2 ye-Welding Wire Production

Iinzuzo zokusebenzisa i-Speed Speed Copper-Coating Line ye-CO2 Welding Wire

Ngokubanzi, izibonelelo zokusebenzisa umgca we-copper-coating high-speed for CO2 welding wire icacile. Ukusuka kwimveliso eyongeziweyo kunye nokugcinwa kweendleko zokuphucula umgangatho kunye nokuzinza kokusingqongileyo, obu buchwepheshe bubonelela ngoluhlu lweenzuzo kubavelisi kunye ne-welders ngokufanayo. Ngokutyala imali kumgca we-copper-coating-coating line-high-speed, abavelisi banokuphucula ukusebenza kocingo lwabo lwe-welding kwaye bahlale phambi kokhuphiswano kwishishini le-welding eqhubekayo.

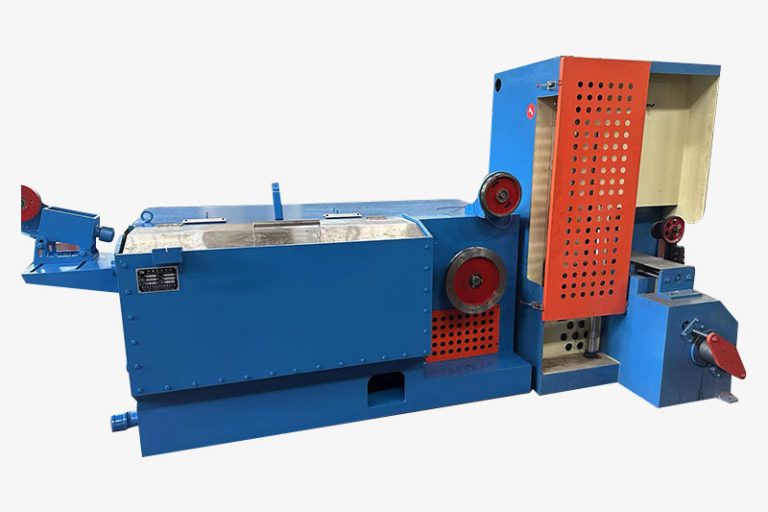

When choosing a high-speed copper-coating line for CO2 welding wire production, it is also important to consider the level of automation and control offered by the machine. Look for a line that features advanced technology and user-friendly controls to streamline the coating process and improve overall efficiency. Automation can help to reduce human error and ensure consistent results, leading to higher quality products.

In conclusion, selecting the right high-speed copper-coating line is essential for achieving success in CO2 welding wire production. Consider factors such as speed, quality, reliability, and automation when making your decision. By choosing a machine that meets your specific manufacturing needs, you can improve efficiency, increase production output, and deliver high-quality welding wire to your customers. Invest in the right equipment today to take your manufacturing operation to the next level.

Benefits of Using a High Speed Copper-Coating Line For CO2 Welding Wire

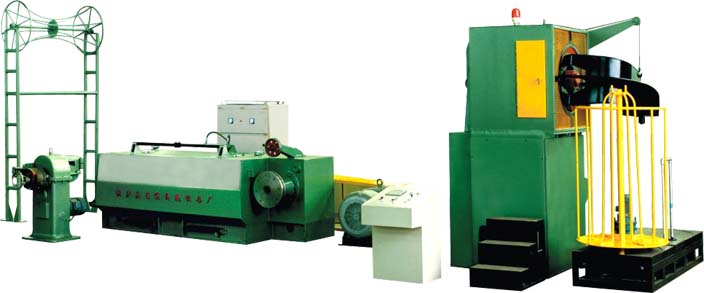

In the world of welding, efficiency and quality are paramount. One key component in the welding process is the welding wire, which plays a crucial role in ensuring a strong and reliable weld. CO2 welding wire is a popular choice for many welding applications due to its versatility and cost-effectiveness. To enhance the performance of CO2 welding wire, many manufacturers are turning to High Speed Copper Coating Production Line For CO2 Welding Wire Line.

Copper-coating is a process in which a thin layer of copper is applied to the surface of the welding wire. This coating serves several important purposes. First and foremost, copper-coating helps to improve the conductivity of the wire, which in turn enhances the welding process. The copper coating also provides a protective barrier against corrosion, ensuring that the wire remains in optimal condition for longer periods of time.

One of the key benefits of using a high-speed copper-coating line for CO2 welding wire is the increased production efficiency it offers. By automating the copper-coating process, manufacturers can significantly reduce the time and labor required to produce large quantities of welding wire. This not only helps to streamline the manufacturing process but also allows for greater output and faster turnaround times.

Furthermore, the use of a high-speed copper-coating line can also lead to cost savings for manufacturers. By increasing production efficiency and reducing labor costs, manufacturers can produce welding wire at a lower cost per unit. This cost savings can then be passed on to customers, making the welding wire more affordable and competitive in the market.

In addition to the economic benefits, a high-speed copper-coating line also helps to improve the quality of the welding wire. The automated nature of the coating process ensures a consistent and uniform coating thickness, which is essential for achieving high-quality welds. This consistency helps to reduce the risk of defects and inconsistencies in the weld, resulting in stronger and more reliable welds.

Another advantage of using a high-speed copper-coating line for CO2 welding wire is the environmental benefits it offers. The copper-coating process is typically more environmentally friendly than other coating methods, as it produces less waste and consumes fewer resources. This can help manufacturers reduce their carbon footprint and operate in a more sustainable manner.

Overall, the benefits of using a high-speed copper-coating line for CO2 welding wire are clear. From increased production efficiency and cost savings to improved quality and environmental sustainability, this technology offers a range of advantages for manufacturers and welders alike. By investing in a high-speed copper-coating line, manufacturers can enhance the performance of their welding wire and stay ahead of the competition in the ever-evolving welding industry.