Table of Contents

Iinzuzo zokuSebenzisa i-Speed High Copper Coating Line ye-CO2 Welding Wire

Indlela yokukhetha umgca weCopper oLungileyo oPhezulu weCopper kwi-CO2 Welding Wire Production

Okokuqala kunye neyona nto iphambili, kubalulekile ukuqwalasela isantya kunye nomthamo womgca wokugubungela ubhedu. Imigca enesantya esiphezulu iyakwazi ukugquma imiqulu emikhulu yocingo ngexesha elifutshane, nto leyo enokunceda ukwandisa imveliso kunye nokusebenza kakuhle ekusebenzeni kwakho. Ukongezelela, uya kufuna ukuqinisekisa ukuba umgca unamandla okuphatha umthamo wocingo oza kuvelisa rhoqo.

Enye into ebalulekileyo ekufuneka uyiqwalasele ngumgangatho wengubo ekwazi ukuvelisa umgca. Ingubo yobhedu ephezulu ibalulekile ekuqinisekiseni ukuba ucingo lwe-welding lusebenza njengoko lulindelwe kwaye luhlangabezana nemigangatho yoshishino. Khangela umgca wokugquma okwaziyo ukuvelisa i-coating ehambelanayo kunye neyomfaniswano kwintambo nganye, njengoko oku kuya kunceda ukunciphisa iziphene kunye nokuqinisekisa umgangatho opheleleyo wemveliso yakho.

Ngaphezu kwesantya kunye nomgangatho, kubalulekile ukuqwalasela. ukuthembeka ngokubanzi kunye nokuqina komgca wokugquma ubhedu. Khangela umatshini owakhiwe ukuba uhlale kwaye unokumelana nobunzima bokusetyenziswa kwansuku zonke kwindawo yokuvelisa. Umatshini othembekileyo uya kunceda ukunciphisa ixesha lokunciphisa kunye neendleko zokulondoloza, ukuqinisekisa ukuba umsebenzi wakho uqhuba kakuhle kwaye ngokufanelekileyo.

Xa ukhetha umgca we-copper high-speed copper, kubalulekile ukuqwalasela inqanaba lokuzenzekelayo kunye nolawulo olunikezwa ngumatshini. Iimpawu ezizenzekelayo zinokunceda ukulungelelanisa inkqubo yokuvelisa kunye nokunciphisa imfuno yokungenelela ngesandla, ngelixa iinkqubo zokulawula eziphambili zinokunceda ekuqinisekiseni ukuba inkqubo yokugubungela iyahambelana kwaye iphinda iphindwe.

Ekugqibeleni, kubalulekile ukuqwalasela iindleko ezipheleleyo zokugubungela ubhedu. line, kubandakanywa zombini utyalo-mali lokuqala kunye neendleko zokusebenza eziqhubekayo. Nangona kunokuba nzima ukukhetha umatshini onexabiso eliphantsi, kubalulekile ukuqwalasela iziphumo zexesha elide zesi sigqibo. Utyalo-mali kumatshini okumgangatho ophezulu, othembekileyo unokubiza ngakumbi ngaphambili, kodwa unokunceda ukugcina imali ngexesha elide ngokunciphisa iindleko zokugcinwa kunye nexesha lokunciphisa.

Ekuqukumbeleni, ukhetha umgca we-copper ochanekileyo wesantya esiphezulu kwi-CO2 welding yakho. imveliso yocingo ibalulekile ekuqinisekiseni iziphumo ezikumgangatho ophezulu kunye nokwandisa ukusebenza kakuhle ekusebenzeni kwakho. Ngokuqwalasela izinto ezinje ngesantya, umgangatho, ukuthembeka, ukuzenzela, kunye neendleko, unokukhetha umatshini ohlangabezana neemfuno zakho ezithile kwaye uncede ukuqhuba impumelelo kwishishini lakho.

Overall, the benefits of using a high-speed copper coating line for CO2 welding wire are clear. From increased production speed and efficiency to improved quality control and safety, this advanced technology offers numerous advantages to manufacturers in the welding industry. By investing in a high-speed copper coating line, manufacturers can position themselves for success in a competitive market and drive continued growth and innovation in their operations.

How to Choose the Right High Speed Copper Coating Line for CO2 Welding Wire Production

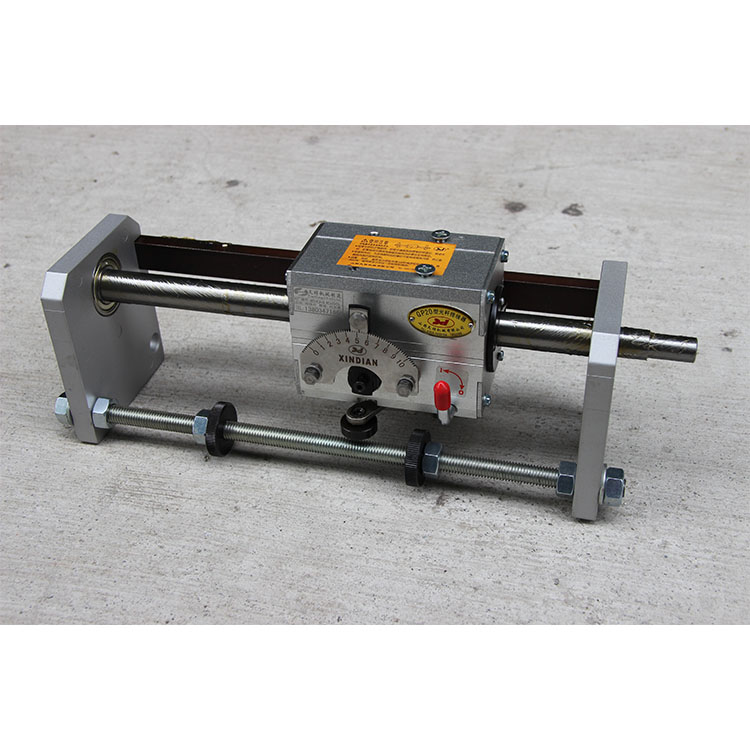

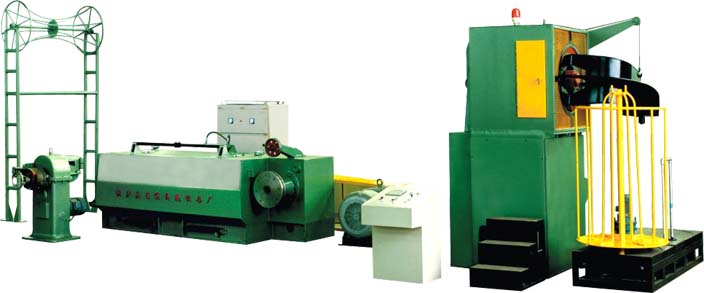

When it comes to CO2 welding wire production, having the right equipment is essential for ensuring high-quality results. One key piece of equipment that is crucial for this process is a high-speed copper coating line. This machine is responsible for applying a thin layer of copper to the surface of the welding wire, which helps to improve its conductivity and overall performance.

Choosing the right High Speed Copper-Coating Line For CO2 Welding Wire production can be a daunting task, as there are many factors to consider. In this article, we will discuss some key considerations to keep in mind when selecting a copper coating line for your operation.

First and foremost, it is important to consider the speed and capacity of the copper coating line. High-speed lines are capable of coating large volumes of wire in a short amount of time, which can help to increase productivity and efficiency in your operation. Additionally, you will want to ensure that the line has the capacity to handle the volume of wire that you will be producing on a regular basis.

Another important factor to consider is the quality of the coating that the line is capable of producing. A high-quality copper coating is essential for ensuring that the welding wire performs as expected and meets industry standards. Look for a coating line that is capable of producing a consistent and uniform coating on each wire, as this will help to minimize defects and ensure the overall quality of your product.

In addition to speed and quality, it is also important to consider the overall reliability and durability of the copper coating line. Look for a machine that is built to last and can withstand the rigors of daily use in a production environment. A reliable machine will help to minimize downtime and maintenance costs, ensuring that your operation runs smoothly and efficiently.

When selecting a high-speed copper coating line, it is also important to consider the level of automation and control that the machine offers. Automated features can help to streamline the production process and reduce the need for manual intervention, while advanced control systems can help to ensure that the coating process is consistent and repeatable.

Finally, it is important to consider the overall cost of the copper coating line, including both the initial investment and ongoing operating costs. While it may be tempting to opt for a lower-cost machine, it is important to consider the long-term implications of this decision. Investing in a high-quality, reliable machine may cost more upfront, but it can help to save money in the long run by reducing maintenance costs and downtime.

In conclusion, choosing the right high-speed copper coating line for your CO2 welding wire production is essential for ensuring high-quality results and maximizing efficiency in your operation. By considering factors such as speed, quality, reliability, automation, and cost, you can select a machine that meets your specific needs and helps to drive success in your business.