Table of Contents

Indlela yokuphucula ukusebenza kakuhle kunye nomgangatho kunye nesantya esiphezulu seCopper-Coating Line ye-CO2 Welding Wire

Iinzuzo zokuSebenzisa i-Speed High Copper Coating Line ye-CO2 Welding Wire

Ukongezelela kwisantya, umgca we-copper-speed high-speed copper uqinisekisa ukuba ubukhulu obufanayo kunye nobukhulu obufanayo. Oku kubalulekile ekuveliseni i-welding wire ekumgangatho ophezulu ehlangabezana nemigangatho yoshishino kunye neenkcukacha. Ngokuphelisa ukuhluka kobuninzi bokugquma, abavelisi banokuphepha iziphene kunye nokungahambelani kwimveliso yokugqibela, okubangela ukuba kuphuculwe umgangatho we-weld kunye nokusebenza.

Ngaphezu koko, ukusetyenziswa komgca we-copper wesantya esiphezulu kunokukhokelela ekugcinweni kweendleko kubakhiqizi. Ngokwandisa ukusebenza kakuhle kwemveliso kunye nokunciphisa inkunkuma, abavelisi banokuthoba iindleko zabo zokuvelisa kunye nokuphucula umgca wabo ophantsi. Ukongezelela, ukuzenzekelayo kwenkqubo yokugubungela kunciphisa imfuno yomsebenzi wezandla, ukugcinwa kweendleko zabasebenzi kunye nokunciphisa umngcipheko wephutha lomntu.

Enye inzuzo yokusebenzisa umgca we-copper high-speed yikhono lokwenza ngokwezifiso inkqubo yokugqoka ukuhlangabezana nayo. iimfuno ezithile. Abavelisi banokuhlengahlengisa isantya, ubushushu, kunye nezinye iiparitha zomgca wokugquma ukufezekisa ubungakanani obufunwayo bokwambatha kunye nomgangatho. Oku kuguquguquka kuvumela abavelisi ukuba balungelelanise inkqubo yabo yokuvelisa ukuhlangabezana neemfuno ezizodwa zabathengi babo kwaye baqinisekise umgangatho ophezulu wokusebenza kwemveliso.

Ukongezelela, umgca we-copper high-speed copper unokuphucula ukhuseleko lomsebenzi ngokunciphisa ukuvezwa kwabasebenzi kwiikhemikhali ezinobungozi. kunye nomsi. Ubume obuzenzekelayo benkqubo yokwaleka kunciphisa imfuno yokuphathwa kweekhemikhali ngesandla, ukunciphisa umngcipheko weengozi kunye nokulimala. Oku akugcini nje ukudala indawo ekhuselekileyo yokusebenza kodwa kunceda abavelisi ukuba bahambelane nemithetho yezempilo kunye nokhuseleko.

Ngokupheleleyo, izibonelelo zokusebenzisa umgca we-copper we-high-speed copper we-CO2 welding wire icacile. Ukusuka kwisantya esongeziweyo semveliso kunye nokusebenza kakuhle ukuya kuphuculo lomgangatho wemveliso kunye nokonga iindleko, obu buchwephesha obuphezulu bubonelela ngeenzuzo ezininzi kubavelisi kwishishini le-welding. Ngotyalo-mali kumgca wokugquma wobhedu onesantya esiphezulu, abavelisi banokuphucula amandla abo emveliso, bahlangabezane neemfuno zabathengi, kwaye bahlale bekhuphisana kwimarike.

Overall, investing in a high-speed copper coating line is a smart decision for manufacturers looking to improve efficiency and quality in the production of CO2 welding wire. By increasing production output, ensuring consistent coating quality, and enhancing workplace safety, these machines offer a range of benefits that can help companies stay competitive in today’s fast-paced manufacturing environment.

In conclusion, a high-speed copper coating line is a valuable tool for manufacturers seeking to optimize their welding wire production process. By leveraging the speed, versatility, and safety features of these machines, companies can achieve higher efficiency, better quality, and increased competitiveness in the market. With the demand for welding wire on the rise, investing in a high-speed copper coating line is a strategic move that can pay off in the long run.

Benefits of Using a High Speed Copper Coating Line for CO2 Welding Wire

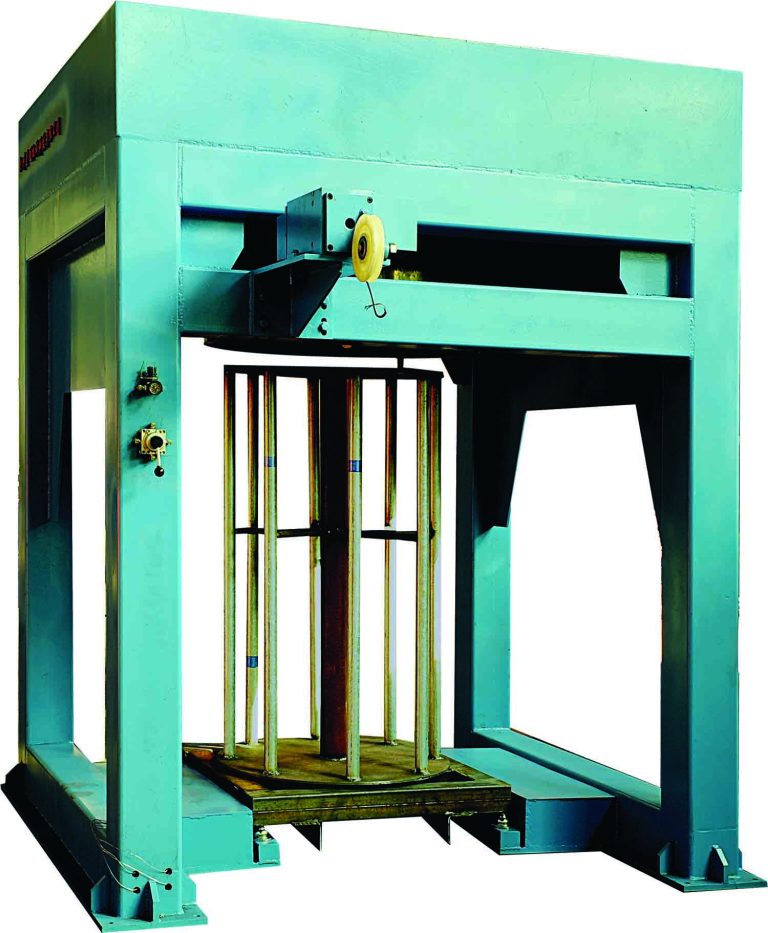

A high-speed copper coating line for CO2 welding wire offers numerous benefits for manufacturers in the welding industry. This advanced technology allows for faster and more efficient production of welding wire, resulting in cost savings and improved product quality.

One of the key advantages of using a high-speed copper coating line is the increased production speed. By automating the coating process, manufacturers can significantly reduce the time it takes to coat the welding wire with copper. This not only allows for higher output levels but also enables manufacturers to meet tight production deadlines and customer demands.

In addition to speed, a high-speed copper coating line also ensures consistent and uniform coating thickness. This is essential for producing high-quality welding wire that meets industry standards and specifications. By eliminating variations in coating thickness, manufacturers can avoid defects and inconsistencies in the final product, resulting in improved weld quality and performance.

Furthermore, the use of a high-speed copper coating line can lead to cost savings for manufacturers. By increasing production efficiency and reducing waste, manufacturers can lower their overall production costs and improve their bottom line. Additionally, the automation of the coating process reduces the need for manual labor, saving on labor costs and minimizing the risk of human error.

Another benefit of using a high-speed copper coating line is the ability to customize the coating process to meet specific requirements. Manufacturers can adjust the speed, temperature, and other parameters of the coating line to achieve the desired coating thickness and quality. This flexibility allows manufacturers to tailor their production process to meet the unique needs of their customers and ensure the highest level of product performance.

Additionally, a high-speed copper coating line can improve workplace safety by reducing the exposure of workers to hazardous chemicals and fumes. The automated nature of the coating process minimizes the need for manual handling of chemicals, reducing the risk of accidents and injuries. This not only creates a safer work environment but also helps manufacturers comply with health and safety regulations.

Overall, the benefits of using a high-speed copper coating line for CO2 welding wire are clear. From increased production speed and efficiency to improved product quality and cost savings, this advanced technology offers numerous advantages for manufacturers in the welding industry. By investing in a high-speed copper coating line, manufacturers can enhance their production capabilities, meet customer demands, and stay competitive in the market.