Izinto eziluncedo zokuSebenzisa kunye ne-nbsp;Ithe nkqo kunye ne-nbsp;Yehlisa iCoiler kunye ne-nbsp; YokuThatha-Up High Carbon Steel Ucingo

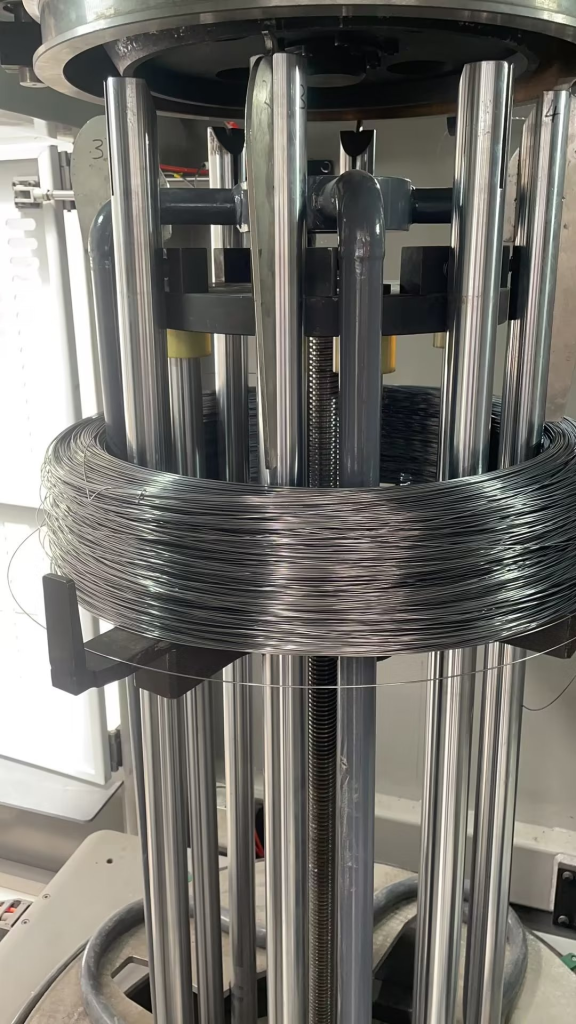

Enye yeenzuzo eziphambili zokusebenzisa i-a kunye ne-nbsp;

Ikhoyila yokuLahla ucingo oluthe nkqoEkuqukumbeleni, i-coiler yokulahla ethe nkqo inikezela ngeenzuzo ezininzi zokuthatha i-carbon steel high wire, kubandakanywa uyilo olugcina indawo, ukuphuculwa kokusebenza kakuhle, isantya esiphezulu, ukuguquguquka, kunye nokhuseleko lomsebenzisi. Ngokwenza utyalo-mali kwi-coiler eyehlayo ethe nkqo, abavelisi banokuphucula umgangatho kunye nemveliso yemisebenzi yabo yokudibanisa, ekugqibeleni ikhokelele kwinkqubo yemveliso elungelelanisiweyo nengabizi kakhulu. for take-up high carbon steel wire is its space-saving design. Unlike horizontal coilers that require a large footprint, Vertical Drop Coilers can be installed in a compact space, making them ideal for facilities with limited floor space. This space-saving design not only helps optimize the use of available space but also allows for easier integration into existing production lines.

In addition to its space-saving design, a vertical drop coiler offers improved efficiency in the coiling process. The vertical orientation of the coiler allows for a more controlled and uniform winding of the high carbon steel wire, resulting in a neater and more organized coil.This high-speed capability is especially beneficial for industries with demanding production schedules and tight deadlines.

Another advantage of using a vertical drop coiler for take-up high carbon steel wire is its versatility. Vertical drop coilers can be easily customized to accommodate different wire diameters, coil sizes, and winding patterns, making them suitable for a wide range of applications. Whether you are coiling thin wire for electrical applications or thick wire for industrial purposes, a vertical drop coiler can be tailored to meet your specific requirements.

Additionally, vertical drop coilers are designed with operator safety in mind. The vertical orientation of the coiler minimizes the risk of injury during coil changes and maintenance tasks, as operators can access the coiling area from a safe distance. This enhanced safety feature helps create a more secure working environment and reduces the likelihood of accidents or injuries on the production floor.

In conclusion, the vertical drop coiler offers several advantages for take-up high carbon steel wire, including space-saving design, improved efficiency, high-speed capability, versatility, and operator safety. By investing in a vertical drop coiler, manufacturers can enhance the quality and productivity of their coiling operations, ultimately leading to a more streamlined and cost-effective production process.