Ukuthelekiswa kohlobo olumanzi lweVs kunye ne-nbsp;Umatshini wokudweba weMicimbi eyomileyo kunye ne-nbsp;Ngocingo lweAluminium

Nangona kunjalo,

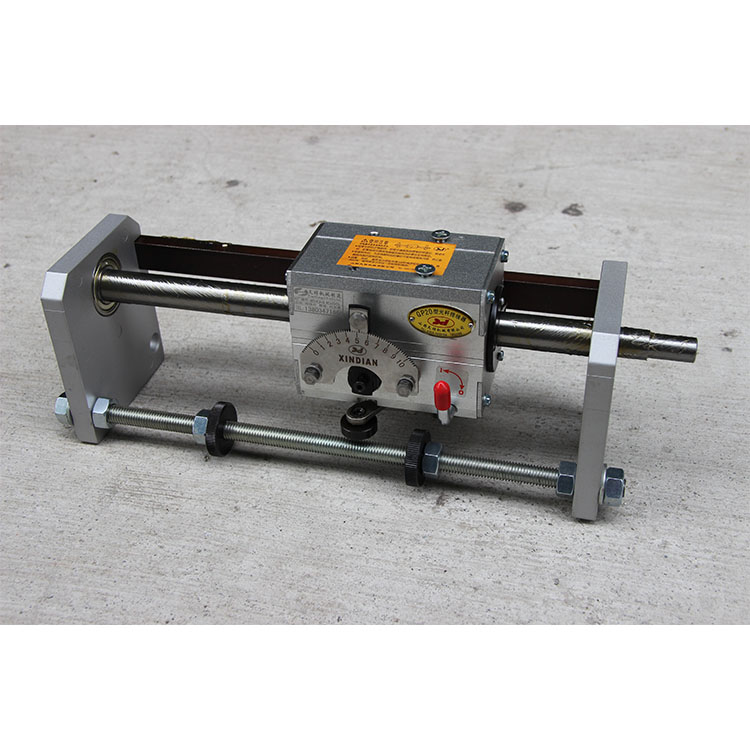

Umatshini wokuzoba woHlulo lweeNgcali

Ekugqibeleni, ukhetho phakathi kohlobo olumanzi kunye nomatshini wokudweba ucingo olomileyo luya kuxhomekeka kwiimfuno ezithile zenkqubo yokuvelisa kunye nomgangatho ofunwayo wemveliso yokugqibela. Abavelisi kufuneka baqwalasele ngononophelo iinzuzo kunye neengozi zohlobo ngalunye lomatshini phambi kokuba benze isigqibo

However, Wire Breakdown Machine Drawing Machine also has some disadvantages. The use of a lubricant can be messy and require additional cleaning and maintenance of the machine. Additionally, the cost of the lubricant can add to the overall operating expenses of the machine.

On the other hand, Dry Type Wire Drawing Machines do not require the use of a lubricant during the drawing process. Instead, the wire is drawn through a series of dies without any additional lubrication. This can result in a simpler and cleaner drawing process, with less maintenance required.

One of the main advantages of dry type wire drawing machines is their lower operating costs. Without the need for a lubricant, manufacturers can save on the cost of purchasing and disposing of lubricants. Additionally, the absence of a lubricant can result in a cleaner working environment, reducing the risk of contamination and improving worker safety.

However, dry type wire drawing machines may not be suitable for all applications. The lack of lubrication can result in increased friction between the wire and the dies, potentially leading to surface defects and reduced wire quality. Additionally, the absence of a lubricant can result in higher operating temperatures, which may affect the overall performance of the machine.

In conclusion, both wet type and dry type wires drawing machines have their own advantages and disadvantages when it comes to drawing aluminium wire. Wet type machines offer high-quality wire with a smooth surface finish, but may require additional maintenance and operating costs. Dry type machines, on the other hand, offer lower operating costs and a cleaner working environment, but may result in lower wire quality.

Ultimately, the choice between wet type and dry type wire drawing machines will depend on the specific requirements of the manufacturing process and the desired quality of the final product. Manufacturers should carefully consider the pros and cons of each type of machine before making a decision.