Ukuphonononga kwe kusebenzisa Flux Cored Welding Wire Surface Grease-Removing Machine

Flux cored kunye nbsp;Umatshini wokuzoba ngocingo lwe-WeldingLilonke, izibonelelo zokusebenzisa i-flux cored welding wire surface-removal machine zicacile. Ukuphuculwa komgangatho we-weld, ukunyuka kwemveliso, kunye nokugcinwa kweendleko zimbalwa zeenzuzo ezinokufunyanwa ngabashicileli ngokubandakanya lo matshini kwinkqubo yabo ye-welding. Nokuba ungumchweli ochwepheshile okanye ungumntu othanda izinto zokuzilibazisa, ukutyala imali kumatshini wokususa igrisi we-flux cored welding kunokukunceda ukuba ufikelele kwiziphumo ezingcono kwaye ulungelelanise imisebenzi yakho yokuwelda.

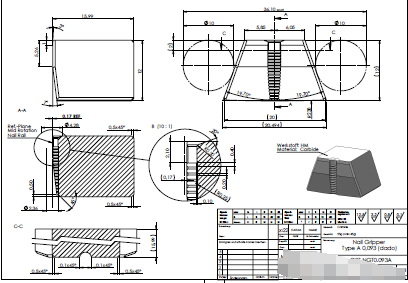

These machines are specifically designed to remove grease and other contaminants from the surface of flux cored welding wire, ensuring a clean and smooth welding process. There are several benefits to using a flux cored welding wire surface grease-removing machine, including improved weld quality, increased productivity, and cost savings.

One of the primary benefits of using a flux cored welding wire surface grease-removing machine is the improved weld quality. Grease and other contaminants on the surface of the welding wire can lead to poor weld penetration, incomplete fusion, and other defects in the finished weld. By removing these contaminants with a grease-removing machine, welders can ensure a clean and strong weld that meets industry standards.

In addition to improving weld quality, using a flux cored welding wire surface grease-removing machine can also increase productivity. Contaminated welding wire can cause interruptions in the welding process, leading to downtime and lost production time. By removing grease and other contaminants from the wire, welders can work more efficiently and complete their projects in a timely manner.

Furthermore, using a flux cored welding wire surface grease-removing machine can result in cost savings for welders. Welding wire is a significant expense for many welding operations, and using contaminated wire can lead to wasted material and increased costs. By ensuring that the welding wire is clean and free of grease, welders can reduce waste and save money on materials.

Overall, the benefits of using a flux cored welding wire surface grease-removing machine are clear. Improved weld quality, increased productivity, and cost savings are just a few of the advantages that welders can experience by incorporating this machine into their welding process. Whether you are a professional welder or a hobbyist, investing in a flux cored welding wire surface grease-removing machine can help you achieve better results and streamline your welding operations.