Table of Contents

Indlela yokuGcina ngokuLungileyo kunye nokuCoca uMshini wokuGxisa uMphezulu oMphezulu

IiNzuzo zokuSebenzisa iFlux Cored Welding Wire kwi-Industrial Applications

Ekuqukumbeleni, i-flux cored welding wire lukhetho oludumileyo kwizicelo zamashishini ngenxa yeenzuzo ezininzi. Ngokusebenzisa umatshini wokususa igrisi we-cored cored welding, abasebenzi bamashishini banokufikelela umgangatho ongcono we-weld, banyuse imveliso, kwaye baphucule ukhuseleko lwabasebenzi. Lo matshini sisixhobo esibalulekileyo kuwo nawuphi na umsebenzi we-welding we-industrial kwaye unokunceda ukuqinisekisa ukuphumelela kwayo nayiphi na iprojekthi ye-welding

In conclusion, proper maintenance and cleaning of a Flux Cored Welding Wire Surface Grease-Removing Machine are essential for ensuring optimal performance and high-quality welds. By regularly cleaning the machine’s components, inspecting for wear or damage, and replacing the cleaning solution as needed, you can keep your machine in top condition and achieve the best results in your welding projects.

Benefits of Using Flux Cored Welding Wire for Industrial Applications

Flux cored welding wire is a popular choice for industrial applications due to its many benefits. One of the key advantages of using flux cored welding wire is its ability to produce high-quality welds with minimal spatter. This is achieved through the use of a flux core that creates a protective gas shield around the weld, preventing oxidation and contamination.

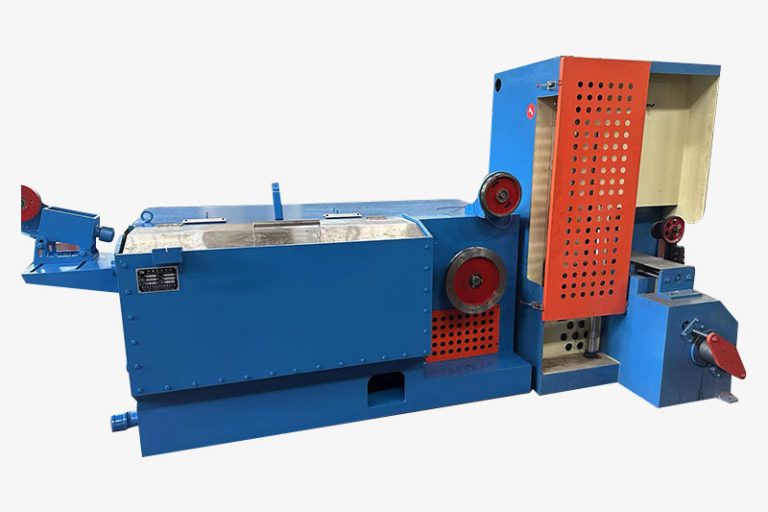

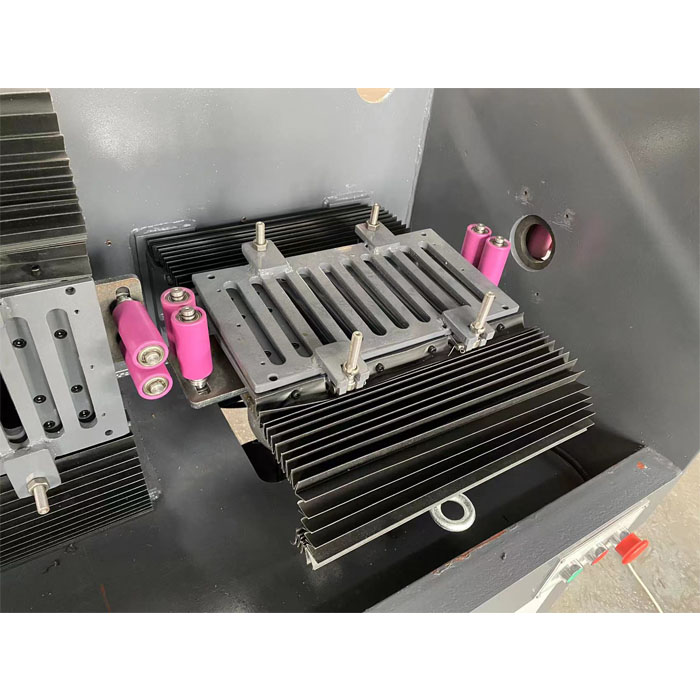

In order to ensure the best results when using flux cored welding wire, it is important to properly prepare the surface of the material being welded. This is where a flux cored welding wire surface grease-removing machine comes into play. This machine is specifically designed to remove any grease or contaminants from the surface of the material, ensuring a clean and smooth welding surface.

By using a flux cored welding wire surface grease-removing machine, industrial workers can achieve better weld quality and reduce the risk of defects in their finished products. This machine is easy to use and can be operated by workers with minimal training, making it a valuable tool for any industrial welding operation.

In addition to improving weld quality, using a flux cored welding wire surface grease-removing machine can also help to increase productivity. By removing grease and contaminants from the surface of the material, workers can achieve faster and more efficient welds, saving time and money in the long run.

Another benefit of using a flux cored welding wire surface grease-removing machine is its ability to improve worker safety. By removing grease and contaminants from the surface of the material, workers are less likely to be exposed to harmful fumes and gases during the welding process. This can help to create a safer work environment and reduce the risk of health problems for workers.

Overall, the use of a flux cored welding wire surface grease-removing machine offers a wide range of benefits for industrial applications. From improving weld quality and productivity to enhancing worker safety, this machine is a valuable tool for any industrial welding operation.

In conclusion, flux cored welding wire is a popular choice for industrial applications due to its many benefits. By using a flux cored welding wire surface grease-removing machine, industrial workers can achieve better weld quality, increase productivity, and improve worker safety. This machine is a valuable tool for any industrial welding operation and can help to ensure the success of any welding project.