Table of Contents

Indlela yokukhetha uMshini oLungileyo wokuGcisa-Ukususa igrisi kwiMisebenzi ye-Welding

IiNzuzo zokuSebenzisa iFlux Cored Welding Wire kwi-Industrial Applications

Ekuqukunjelweni, i-flux cored welding wire surface-removing machines ziyi-asethi exabisekileyo kumaziko oshishino axhomekeke kwi-flux cored welding wire kwiimfuno zabo ze-welding. Ngokususa igrisi engaphezulu kwi-welding wire, aba matshini banceda ukuphucula umgangatho we-weld, ukwandisa imveliso, kunye nokubonelela ngesisombululo esinexabiso elisebenzayo kwizicelo zamashishini. Ngeenzuzo zabo ezininzi, oomatshini bokususa igrisi be-flux cored cored wire basisisixhobo ekufuneka ubenaso kuso nasiphi na isixhobo somzi-mveliso esijonge ukufikelela kwiiwelds ezikumgangatho ophezulu ngexesha nangendlela efanelekileyo.

When choosing a surface grease-removing machine for welding operations, it is also important to consider the ease of use and maintenance of the machine. The machine should be user-friendly, with clear instructions and controls that are easy to understand. It should also be easy to clean and maintain, with accessible parts and components that can be easily replaced or repaired if necessary.

In conclusion, choosing the right surface grease-removing machine for welding operations is essential for achieving clean and efficient welding processes. By considering factors such as the type of contaminants to be removed, the size and capacity of the machine, its efficiency and effectiveness, cost, and ease of use and maintenance, welding operations can select a machine that meets their specific needs and requirements. Investing in a high-quality surface grease-removing machine can help to improve the quality and integrity of welding operations, leading to better results and increased productivity.

Benefits of Using Flux Cored Welding Wire for Industrial Applications

Flux cored welding wire is a popular choice for industrial applications due to its many benefits. One of the key advantages of using flux cored welding wire is its ability to produce high-quality welds in a variety of conditions. This type of welding wire is designed to create strong, durable welds that can withstand the rigors of industrial use.

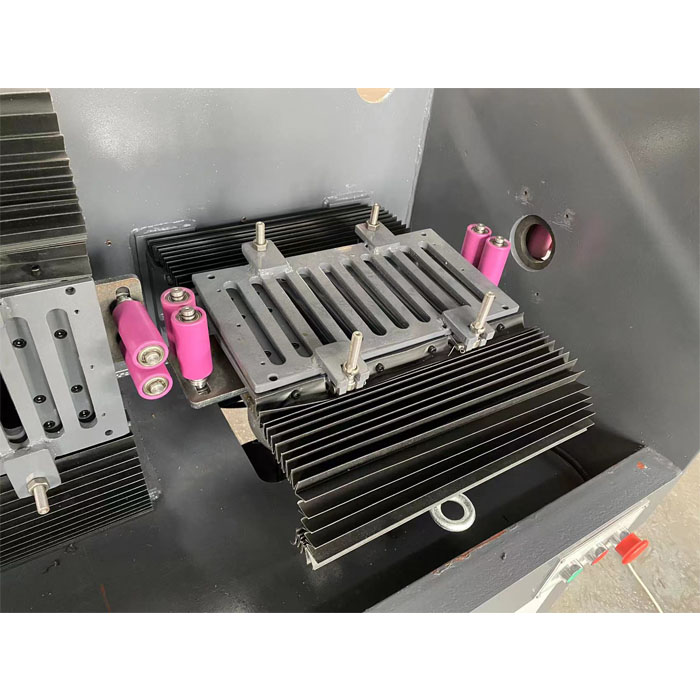

One of the challenges of using flux cored welding wire is the presence of surface grease on the wire. This grease can interfere with the welding process, leading to poor weld quality and potentially compromising the integrity of the finished product. To address this issue, many industrial facilities use Flux Cored Welding Wire Surface Grease-Removing Machines.

These machines are specifically designed to remove surface grease from flux cored welding wire, ensuring that the wire is clean and ready for use in the welding process. By removing surface grease, these machines help to improve the quality of the welds produced, resulting in stronger, more reliable finished products.

In addition to improving weld quality, flux cored welding wire surface grease-removing machines also help to increase productivity in industrial settings. By automating the process of removing surface grease from welding wire, these machines save time and labor, allowing workers to focus on other tasks.

Furthermore, flux cored welding wire surface grease-removing machines are easy to use and maintain, making them a cost-effective solution for industrial facilities. These machines are designed to be durable and reliable, ensuring that they can withstand the demands of a busy industrial environment.

Overall, flux cored welding wire surface grease-removing machines offer a number of benefits for industrial applications. By improving weld quality, increasing productivity, and providing a cost-effective solution for removing surface grease from welding wire, these machines are an essential tool for any industrial facility looking to achieve high-quality welds in a timely and efficient manner.

In conclusion, flux cored welding wire surface grease-removing machines are a valuable asset for industrial facilities that rely on flux cored welding wire for their welding needs. By removing surface grease from welding wire, these machines help to improve weld quality, increase productivity, and provide a cost-effective solution for industrial applications. With their many benefits, flux cored welding wire surface grease-removing machines are a must-have tool for any industrial facility looking to achieve high-quality welds in a timely and efficient manner.