Table of Contents

IiNzuzo zokuSebenzisa iFlux Cored Welding Wire kwi-Industrial Applications

Indlela yokuGcina ngokufanelekileyo kunye nokuCoca uMshini wokuGwamisa uMphezulu woMshini wokuzoba ngocingo

Ukugcinwa ngokufanelekileyo kunye nokucocwa komatshini wokususa igrisi kumphezulu womatshini wokudweba ucingo kubalulekile ekuveliseni i-welds ephezulu. Ngokulandela ezi ngcebiso kunye nezikhokelo, i-welders inokuqinisekisa ukuba izixhobo zabo zisebenza ngokufanelekileyo nangempumelelo. Khumbula ukucoca umatshini rhoqo, sebenzisa izisombululo zokucoca ezifanelekileyo, kwaye uhlole naziphi na iimpawu zokuguga okanye umonakalo. Ngokhathalelo olufanelekileyo kunye nokugcinwa okufanelekileyo, umatshini wokususa igrisi ongaphezulu unokuqhubeka nokuvelisa i-welds ephezulu kwiminyaka ezayo.

Flux cored welding wire is a popular choice for many welding applications due to its high efficiency and cost-effectiveness. However, in order to ensure the quality of the welds produced, it is important to properly maintain and clean the surface grease-removing machine used in the wire drawing process.

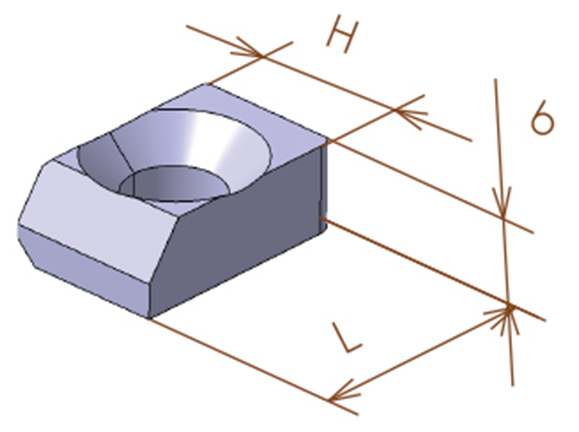

One of the key components of a surface grease-removing machine is the wire drawing machine. This machine is responsible for pulling the flux cored welding wire through a series of dies to reduce its diameter and improve its surface finish. In order for the wire drawing machine to operate efficiently, it is essential that the surface grease-removing machine is kept clean and well-maintained.

To properly maintain a surface grease-removing machine, it is important to regularly clean and inspect all components of the machine. This includes the wire drawing dies, rollers, and brushes. Any buildup of grease or debris on these components can negatively impact the performance of the machine and result in poor quality welds.

When cleaning the surface grease-removing machine, it is important to use the appropriate cleaning solution and tools. Avoid using harsh chemicals or abrasive materials that could damage the machine. Instead, opt for a mild detergent or solvent that is safe for use on metal surfaces.

Start by disconnecting the machine from power and removing any wire or components that may obstruct the cleaning process. Use a soft brush or cloth to gently scrub away any grease or debris from the surface of the machine. Pay close attention to areas where grease tends to accumulate, such as around the wire drawing dies and rollers.

After cleaning the surface grease-removing machine, it is important to thoroughly dry all components before reassembling the machine. Moisture left on the machine can lead to rust and corrosion, which can further impact the performance of the machine.

In addition to regular cleaning, it is also important to inspect the surface grease-removing machine for any signs of wear or damage. Check for loose or worn components, such as brushes or rollers, and replace them as needed. Keeping the machine in good working condition will help to prolong its lifespan and ensure consistent weld quality.

Proper maintenance and cleaning of a surface grease-removing machine for a wire drawing machine is essential for producing high-quality welds. By following these tips and guidelines, welders can ensure that their equipment operates efficiently and effectively. Remember to clean the machine regularly, use the appropriate cleaning solutions, and inspect for any signs of wear or damage. With proper care and maintenance, a surface grease-removing machine can continue to produce top-notch welds for years to come.