Table of Contents

Iingcebiso zoLondolozo lweGubu lokuPakisha oomatshini bocingo lwe-Welding

Uomatshini bokupakisha i-Drum sisixhobo esibalulekileyo kwishishini le-welding wire, njengoko livumela ukupakishwa okusebenzayo kunye nokuchanekileyo kwe-welding wire kwi-drums. Ukugcinwa ngokufanelekileyo koomatshini bokupakisha igubu kubalulekile ukuze kuqinisekiswe ubomi obude kunye nokusebenza kakuhle. Kweli nqaku, siza kuxoxa ngezinye iingcebiso zogcino koomatshini bokupakisha igubu locingo lwe-welding.

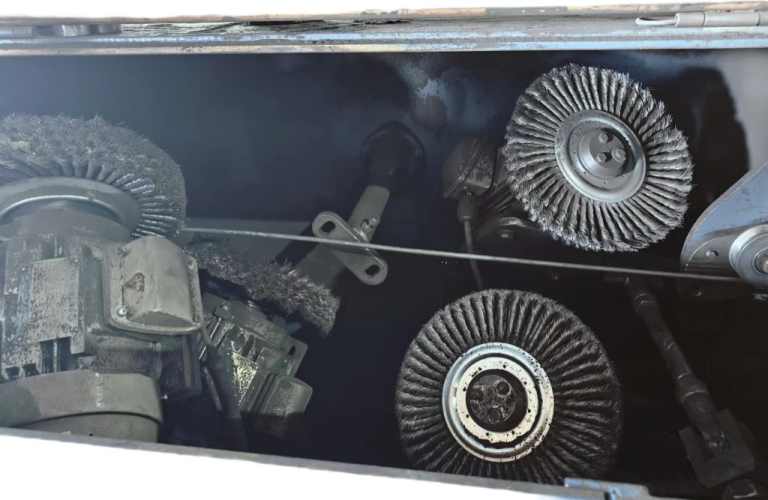

Omnye weyona misebenzi ibalulekileyo yokulondolozwa koomatshini bokupakisha igubu kukucoca rhoqo. Uthuli, inkunkuma, kunye nolunye ungcoliseko lunokwakhelana koomatshini ekuhambeni kwexesha, nto leyo ekhokelela ekucuthekeni kokusebenza kunye nomonakalo onokwenzeka. Kucetyiswa ukuba ucoce oomatshini emva kokusetyenziswa ngakunye, usebenzisa ibhrashi ethambileyo okanye ilaphu ukususa nayiphi na into eyakhiweyo. Ukongeza, kubalulekile ukubahlola rhoqo oomatshini ukuba kukho naziphi na iimpawu zokuguga okanye ukonakaliswa, okufana neebholiti ezixegayo okanye iindawo ezigugileyo.

Enye ingcebiso engundoqo yokulondolozwa koomatshini bokupakisha igubu kukuthambisa rhoqo iindawo ezihambayo. Ukuthambisa okufanelekileyo kunceda ukunciphisa ukukhuhlana kunye nokunxiba koomatshini, ukwandisa ixesha lokuphila kunye nokuqinisekisa ukusebenza kakuhle. Kubalulekile ukusebenzisa uhlobo oluchanekileyo lwesithambiso kwindawo nganye yomatshini, njengoko ukusebenzisa uhlobo olungalunganga kunokubangela umonakalo. Ukongeza, kuyacetyiswa ukuba ulandele izikhokelo zomenzi malunga nobuninzi bokuthambisa kunye nobungakanani.

Ukongeza ekucoceni nasekuthambiseni, kubalulekile ukuhlola rhoqo kunye nokutshintsha iindawo ezigugileyo koomatshini bokupakisha amagubu. Ngokuhamba kwexesha, iinxalenye ezinjengamabhanti, amatyathanga, neebheringi zinokuguga kwaye zifuna ukutshintshwa. Ukuhlola la malungu rhoqo kunye nokuwatshintsha njengoko kufuneka kunokunceda ukuthintela ukophuka kunye nokuqinisekisa ukuba oomatshini bayaqhubeka nokusebenza kakuhle.

Ukulinganiswa ngokufanelekileyo koomatshini bokupakisha igubu nako kubalulekile ekusebenzeni ngokupheleleyo. Ulungelelwaniso luqinisekisa ukuba oomatshini balinganisa ngokuchanekileyo kwaye bapakisha ucingo lwe-welding kumagubhu. Kucetyiswa ukulinganisa oomatshini rhoqo, ngokulandela izikhokelo zomenzi kwiinkqubo zokulinganisa. Ukongeza, kubalulekile ukugcina iirekhodi ezichanekileyo zemihla yokulinganisa kunye neziphumo zokukhangela kwixesha elizayo.

Indlela yokukhetha uMshini wokuPakisha iGubu eliLungileyo locingo lwe-Welding

Enye into ebalulekileyo ekufuneka iqwalaselwe xa ukhetha igubu lokupakisha oomatshini bocingo lwe-welding sisantya sokupakisha esifunwayo. Isantya sokupakisha soomatshini bokupakisha igubu sinokwahluka kakhulu, ngoomatshini abathile abakwaziyo ukupakisha amakhulu emigqomo ngeyure. Kubalulekile ukuqwalasela umthamo wocingo lwe-welding olufuna ukupakishwa kwaye ukhethe oomatshini onokuhlangabezana nesantya esifunekayo sokupakisha. Ukukhetha oomatshini abacothayo kakhulu kunokukhokelela kwimiqobo kwimveliso, ngelixa ukukhetha oomatshini abakhawuleza kakhulu kunokungeyomfuneko kwaye kubize kakhulu.

Ngaphezu kohlobo locingo lwe-welding kunye nesantya sokupakisha, uhlahlo lwabiwo-mali lukwayingqwalasela ebalulekileyo xa ukhetha ukupakisha igubu. oomatshini bocingo lwe-welding. Oomatshini bokupakisha igubu banokwahluka kakhulu kwixabiso, ngokuxhomekeke kwizinto ezifana nophawu, ubungakanani, kunye neempawu zomatshini. Kubalulekile ukuseta uhlahlo lwabiwo-mali kwaye ukhethe oomatshini abangena ngaphakathi kohlahlo lwabiwo-mali ngelixa behlangabezana neemfuno eziyimfuneko zokupakisha ucingo lwe-welding. Kunokuba luncedo ukuthelekisa amaxabiso kunye neempawu zeendlela ezahlukeneyo zoomatshini bokupakisha igubu ukufumana elona xabiso lilungileyo lemali.

Xa ukhetha umatshini wokupakisha igubu locingo lwe-welding, kukwabalulekile ukuqwalasela ukuthembeka kunye nokuqina komatshini. Oomatshini bokupakisha igubu lutyalo-mali olubalulekileyo, kwaye kubalulekile ukukhetha oomatshini abakhelwe ukuhlala kwaye banokumelana nobunzima bokusetyenziswa kwemihla ngemihla. Kuluncedo ukuphanda isidima somenzi nokufunda uphononongo oluvela kwabanye abasebenzisi ukuqinisekisa ukuba oomatshini bathembekile kwaye bahlala ixesha elide.

Ekuqukumbeleni, ukukhetha umatshini wokupakisha igubu elifanelekileyo locingo lwewelding kubalulekile ekuqinisekiseni ukupakishwa okusebenzayo kunye nokuthuthwa kwewelding. ucingo. Izinto ekufuneka ziqwalaselwe xa ukhetha oomatshini bokupakisha igubu ziquka uhlobo locingo lwe-welding olupakishwayo, isantya esifunwayo sokupakisha, uhlahlo lwabiwo-mali, kunye nokuthembeka kunye nokuqina komatshini. Ngokuqwalasela ngononophelo ezi zinto kunye nokukhetha oomatshini abahlangabezana neemfuno eziyimfuneko, abavelisi becingo lokuwelda banokwandisa imveliso kwaye balungelelanise imisebenzi yabo.

Drum packing machinery plays a crucial role in the welding wire industry, as it helps to efficiently package and transport welding wire in large quantities. Choosing the right Welding Wire Drum Packer machinery is essential for ensuring smooth operations and maximizing productivity. There are several factors to consider when selecting Drum Packing Machinery For Welding Wire, including the type of welding wire being packaged, the desired packaging speed, and the available budget.

One of the first things to consider when choosing drum packing machinery for welding wire is the type of welding wire being packaged. Different types of welding wire may require different packaging methods and machinery. For example, solid welding wire may require a different type of drum packing machinery than flux-cored welding wire. It is important to choose machinery that is specifically designed to handle the type of welding wire being packaged to ensure optimal performance and efficiency.

Another important factor to consider when selecting drum packing machinery for welding wire is the desired packaging speed. The packaging speed of drum packing machinery can vary greatly, with some machines capable of packaging hundreds of drums per hour. It is important to consider the volume of welding wire that needs to be packaged and choose machinery that can meet the required packaging speed. Choosing machinery that is too slow can lead to bottlenecks in production, while choosing machinery that is too fast may be unnecessary and costly.

In addition to the type of welding wire and packaging speed, budget is also an important consideration when choosing drum packing machinery for welding wire. Drum packing machinery can vary greatly in price, depending on factors such as the brand, size, and features of the machine. It is important to set a budget and choose machinery that fits within that budget while still meeting the necessary requirements for packaging welding wire. It may be helpful to compare prices and features of different drum packing machinery options to find the best value for money.

When choosing drum packing machinery for welding wire, it is also important to consider the reliability and durability of the machine. Drum packing machinery is a significant investment, and it is important to choose machinery that is built to last and can withstand the rigors of daily use. It is helpful to research the reputation of the manufacturer and read reviews from other users to ensure that the machinery is reliable and durable.

In conclusion, choosing the right drum packing machinery for welding wire is essential for ensuring efficient packaging and transportation of welding wire. Factors to consider when selecting drum packing machinery include the type of welding wire being packaged, the desired packaging speed, budget, and the reliability and durability of the machine. By carefully considering these factors and choosing machinery that meets the necessary requirements, welding wire manufacturers can maximize productivity and streamline their operations.