Table of Contents

IiNzuzo zokuSebenzisa oomatshini bokuPakisha iGubu loNxibelelwano lwe-Welding

Indlela yokukhetha uMshini wokuPakisha iGubu eliLungileyo kwi-Welding Wire

Ivolumu yokuvelisa yenye into ebalulekileyo ekufuneka iqwalaselwe xa ukhetha umatshini wokupakisha igubu kwi-welding wire. Umthamo wemveliso uya kugqiba ubungakanani kunye namandla oomatshini abafunekayo ukuhlangabezana nemfuno. Ukuveliswa kwevolumu ephezulu, umatshini omkhulu kunye nomatshini wokupakisha owenziwe ngokuzenzekelayo unokufuneka ukuze kuqinisekiswe ukupakishwa okusebenzayo kunye nokunciphisa ixesha lokuphumla. Ngakolunye uhlangothi, kwimiqulu emincinci yokuvelisa, umatshini omncinci kunye nangaphezulu wokupakisha igubu unokwanela.

Imithintelo yohlahlo lwabiwo-mali nayo iyingqwalasela ephambili xa ukhetha umatshini wokupakisha umgqomo wocingo lwe-welding. Iindleko zoomatshini bokupakisha igubu zinokuhluka ngokubanzi ngokuxhomekeke kubungakanani, umthamo, kunye neempawu zomatshini. Kubalulekile ukuqwalasela ngononophelo imiqobo yohlahlo lwabiwo-mali kwaye ulinganise iindleko zoomatshini ngokuchasene noncedo oluza kubonelela. Kwezinye iimeko, ukutyala imali koomatshini abakumgangatho ophezulu kunokubangela ukongiwa kweendleko zexesha elide ngokwandisa ukusebenza kakuhle kunye nokunciphisa ixesha lokuphumla.

Xa ukhetha oomatshini bokupakisha igubu locingo lwe-welding, kubalulekile ukuqwalasela ukusebenza kakuhle kunye nokuthembeka komatshini. Khangela oomatshini ekulula ukusebenza kunye nokugcina, kunye nerekhodi eqinisekisiweyo yokuthembeka. Qwalasela igama lomenzi kwaye ufunde uphononongo oluvela kwabanye abasebenzisi ukuqinisekisa ukuba oomatshini baya kuhlangabezana neemfuno zakho kunye nezinto ozilindeleyo.

Ekuqukumbeleni, ukukhetha umatshini ofanelekileyo wokupakisha igubu locingo lwewelding kubalulekile ukuqinisekisa ukupakishwa okusebenzayo kunye nokuthuthwa kocingo lwe-welding. Qwalasela uhlobo locingo lwe-welding olupakishwayo, umthamo wemveliso, imiqobo yebhajethi, kunye nokusebenza kakuhle kunye nokuthembeka xa ukhetha oomatshini bokupakisha igubu. Ngokuqwalasela ngononophelo ezi zinto kunye nokukhetha oomatshini abakumgangatho ophezulu, unokuqinisekisa ukusebenza okugudileyo kunye nokupakishwa okukumgangatho ophezulu kwiimveliso zakho zocingo lokuwelda.

How to Choose the Right Drum Packing Machinery For Welding Wire

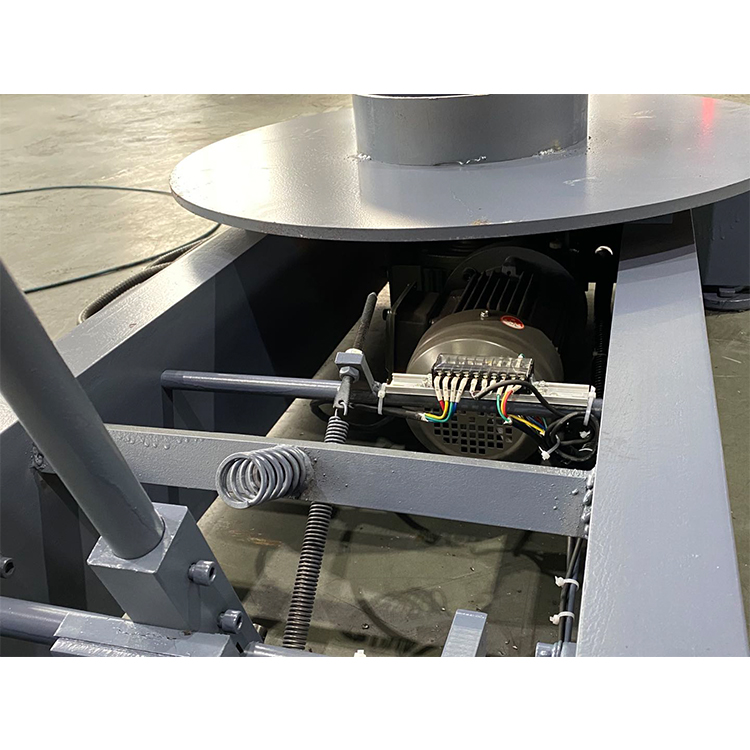

Drum packing machinery plays a crucial role in the welding wire industry, as it helps to efficiently package and transport welding wire in large quantities. Choosing the right drum packing machinery is essential to ensure smooth operations and high-quality packaging. There are several factors to consider when selecting drum packing machinery for welding wire, including the type of welding wire being packaged, production volume, and budget constraints.

One of the first considerations when choosing drum packing machinery for welding wire is the type of welding wire being packaged. Different types of welding wire may require different packaging materials and machinery. For example, some welding wires may be more prone to tangling or breaking during packaging, requiring specialized machinery to handle them properly. It is important to consider the specific requirements of the welding wire being packaged to ensure that the drum packing machinery can meet these needs.

Production volume is another important factor to consider when choosing drum packing machinery for welding wire. The production volume will determine the size and capacity of the machinery needed to meet demand. For high-volume production, a larger and more automated drum packing machine may be necessary to ensure efficient packaging and minimize downtime. On the other hand, for smaller production volumes, a smaller and more manual drum packing machine may be sufficient.

Budget constraints are also a key consideration when selecting drum packing machinery for welding wire. The cost of drum packing machinery can vary widely depending on the size, capacity, and features of the machine. It is important to carefully consider budget constraints and weigh the cost of the machinery against the benefits it will provide. In some cases, investing in higher-quality machinery may result in long-term cost savings through increased efficiency and reduced downtime.

When choosing drum packing machinery for welding wire, it is important to consider the overall efficiency and reliability of the machine. Look for machinery that is easy to operate and maintain, with a proven track record of reliability. Consider the reputation of the manufacturer and read reviews from other users to ensure that the machinery will meet your needs and expectations.

In conclusion, choosing the right drum packing machinery for welding wire is essential to ensure efficient packaging and transportation of welding wire. Consider the type of welding wire being packaged, production volume, budget constraints, and overall efficiency and reliability when selecting drum packing machinery. By carefully considering these factors and choosing high-quality machinery, you can ensure smooth operations and high-quality packaging for your welding wire products.