Table of Contents

IiNzuzo zokuSebenzisa umatshini wokuzoba ngocingo olumanzi lweCopper kwii-Industrial Applications

Indlela yokukhetha umatshini wokuzoba weCopper oLungileyo kwiShishini lakho

Ekuqukumbeleni, ukukhetha umatshini wokuzoba ngocingo lobhedu olufanelekileyo kwishishini lakho kubalulekile ukuqinisekisa imveliso esebenzayo kunye nemveliso ephezulu. Qwalasela izinto ezifana nobukhulu bocingo, amandla okuvelisa, isantya kunye nokusebenza kakuhle, umgangatho kunye nokuqina, ukuzenzekelayo kunye neempawu zokulawula, iimpawu zokhuseleko kunye neendleko xa ukhetha umatshini. Ngokuvavanya ngononophelo ezi zinto kwaye ukhethe umatshini ohlangabezana neemfuno zakho ezithile, unokuphucula imveliso kunye nenzuzo yeshishini lakho.

How to Choose the Right Copper Wire Drawing Machine for Your Business

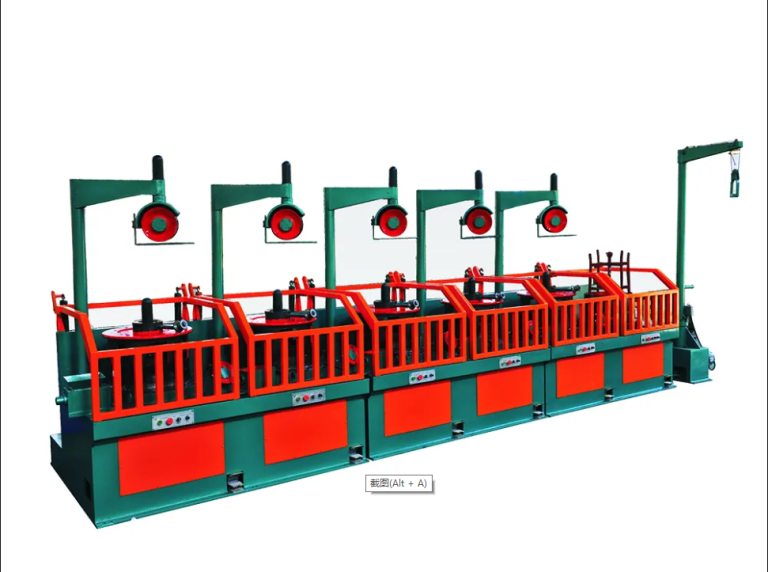

Copper Wire Breakdown Machine Drawing Machine is essential equipment for businesses involved in the production of copper wires. These machines are used to reduce the diameter of copper rods or wires by pulling them through a series of dies, resulting in a smoother and more uniform wire. Choosing the right copper wire drawing machine for your business is crucial to ensure efficient production and high-quality output.

When selecting a copper wire drawing machine, there are several factors to consider. The first consideration is the size and type of copper wire you will be producing. Different machines are designed to handle different wire sizes and types, so it is important to choose a machine that is suitable for your specific production needs. Additionally, consider the production capacity of the machine. If you have a high volume of wire production, you will need a machine that can handle the workload efficiently.

Another important factor to consider is the speed and efficiency of the machine. Look for a machine that can draw wire at a consistent speed and with minimal downtime. This will help to maximize productivity and reduce production costs. Additionally, consider the power consumption of the machine. Choose a machine that is energy-efficient to help reduce operating costs and minimize environmental impact.

It is also important to consider the quality and durability of the machine. Look for a machine that is made from high-quality materials and is built to last. A durable machine will require less maintenance and repair, saving you time and money in the long run. Additionally, consider the reputation of the manufacturer. Choose a machine from a reputable manufacturer with a track record of producing high-quality equipment.

When choosing a copper wire drawing machine, it is also important to consider the level of automation and control features. Some machines come with advanced automation features that allow for precise control over the drawing process. These features can help to improve the quality and consistency of the wire produced. Additionally, consider the safety features of the machine. Look for a machine that is equipped with safety guards and emergency stop buttons to protect operators from accidents.

Finally, consider the cost of the machine. While it is important to choose a machine that meets your production needs, it is also important to consider your budget. Compare prices from different manufacturers and choose a machine that offers the best value for your money. Keep in mind that investing in a high-quality machine may cost more upfront but can save you money in the long run by reducing maintenance and repair costs.

In conclusion, choosing the right copper wire drawing machine for your business is essential to ensure efficient production and high-quality output. Consider factors such as wire size, production capacity, speed and efficiency, quality and durability, automation and control features, safety features, and cost when selecting a machine. By carefully evaluating these factors and choosing a machine that meets your specific needs, you can improve the productivity and profitability of your business.