Table of Contents

Indlela yokwandisa ukusebenza kakuhle kunye nomgangatho ngesantya esiphezulu seCopper-Coating Line kwi-CO2 Welding Wire

I-Copper-coating linyathelo elibalulekileyo kwinkqubo yokuvelisa kunye ne-nbsp;

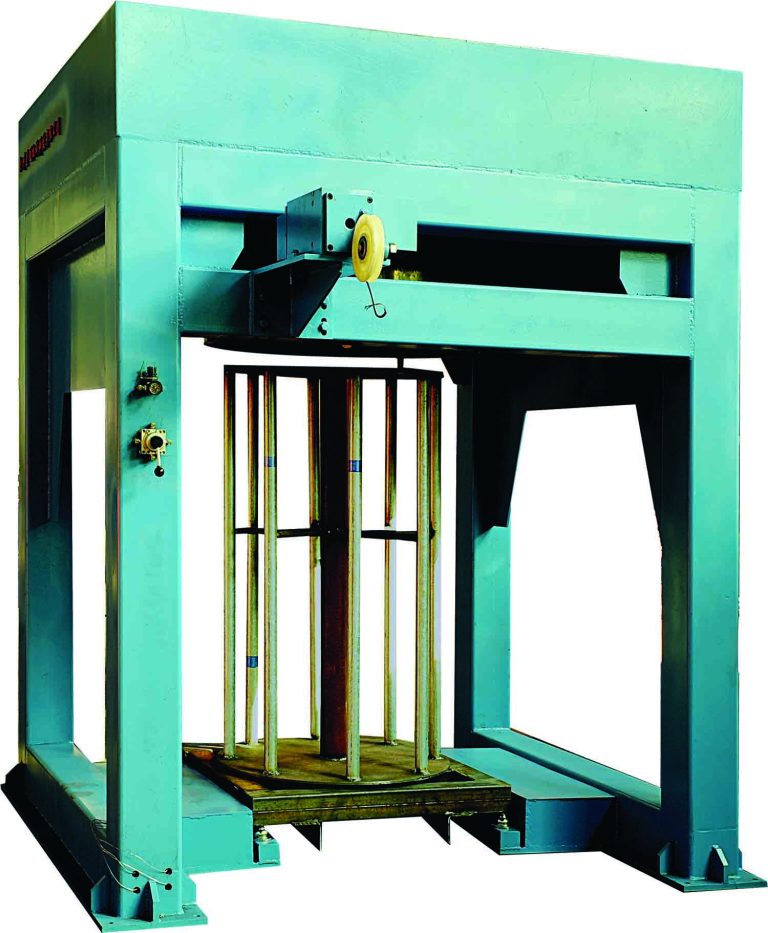

Umgca weMveliso yeCopper yesantya esiphezulu kwi-CO2 Welding Wire LineNgaphezu koko, a kunye ne-nbsp;umgca we-copper-coating high-speed

kunye ne-nbsp; inokunceda ukunciphisa inkunkuma kunye nokuphucula ukusebenza kakuhle kweendleko. Ngokwandisa ukusebenza kakuhle kwenkqubo yokugubungela, abavelisi banokunciphisa inani lezinto ezichithwayo ngexesha lokuvelisa. Oku akugcini nje kuphela kongi imali kodwa kwakhona kunciphisa impembelelo yokusingqongileyo yenkqubo yokuvelisa.

Ukuqonda Ukusebenzisa i-Speed High Copper Coating Line kwi-CO2 Welding Wire

Ehlabathini lokuvelisa, ukusebenza kakuhle kunye nomgangatho zizinto eziphambili ekuqinisekiseni impumelelo yemveliso. Xa kufikwa kwi-CO2 yokuwelda ucingo, ukuba ne-a kunye ne-nbsp;Isantya esiphezulu seCopper-Coating Line For CO2 Welding WireUkongezelela, umgca we-copper-coating high-speed uvumela ukunyuka kwamandla okuvelisa. Ngokugquma ucingo ngesantya esikhawulezayo, abavelisi banokuvelisa ngakumbi ucingo lwe-welding ngexesha elifutshane. Oku akuphuculi nje ukusebenza kakuhle kodwa kukwavumela imveliso enkulu, ukuhlangabezana neemfuno zommandla wokuvelisa okhawulezayo.

Enye inzuzo yokusebenzisa umgca we-high-speed copper-coating ngumgangatho ophuculweyo we-welding wire. Ukugqoka okufanayo okubonelelwa ngobuchwepheshe obuphambili buqinisekisa ukuba ucingo alunaziphene kunye nokungahambelani. Oku kuphumela kwimveliso ekumgangatho ophezulu ehlangabezana nemigangatho yoshishino kunye nolindelo lwabathengi.

Ekuqukunjelweni, ukusetyenziswa komgca we-copper-coating high-speed kwi-CO2 welding wire yi-investment exabisekileyo kubavelisi abafuna ukuphucula inkqubo yabo yokuvelisa. Ngokukwazi kwayo ukubonelela ngokuguquguqukayo kunye nokwaleka okufanayo, ukwandisa umthamo wemveliso, ukunciphisa iindleko, kunye nokuphucula umgangatho, obu buchwepheshe buqhubela phambili bubonelela ngoluhlu lweenzuzo ezinokuthi zibe nempembelelo ebalulekileyo kwimpumelelo yonke yemveliso. Ngokubandakanya umgca ohamba ngesantya esiphezulu kwinkqubo yabo yokuvelisa, iinkampani zinokuhlala phambi kokhuphiswano kwaye zihlangabezane neemfuno zeshishini elikhawulezayo.

Understanding Of Using A High Speed Copper Coating Line For CO2 Welding Wire

In the world of manufacturing, efficiency and quality are key factors in determining the success of a product. When it comes to CO2 welding wire, having a High Speed Copper-Coating Line For CO2 Welding Wire can make a significant difference in the overall production process. This advanced technology offers a range of benefits that can improve the quality of the welding wire and increase productivity.

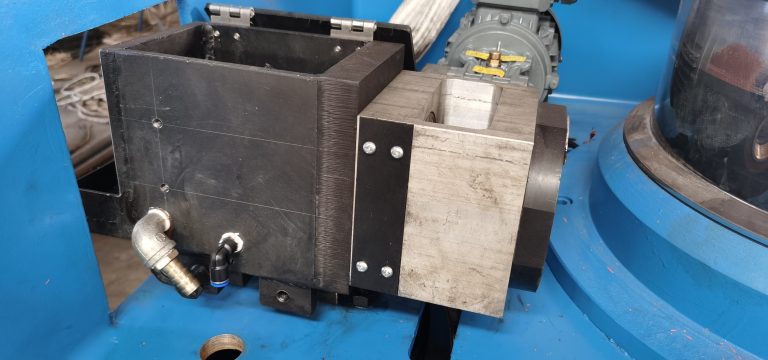

One of the main advantages of using a high-speed copper-coating line for CO2 welding wire is the ability to produce a consistent and uniform coating on the wire. This is essential for ensuring that the wire performs optimally during the welding process. With a high-speed line, the coating is applied quickly and evenly, resulting in a smooth and reliable finish on the wire.

Additionally, the high-speed copper-coating line allows for increased production capacity. By coating the wire at a faster rate, manufacturers can produce more welding wire in a shorter amount of time. This not only improves efficiency but also allows for greater output, meeting the demands of a fast-paced manufacturing environment.

Furthermore, the use of a high-speed copper-coating line can lead to cost savings for manufacturers. By increasing production capacity and efficiency, companies can reduce their overall production costs. This can result in higher profit margins and a competitive edge in the market.

Another benefit of using a high-speed copper-coating line is the improved quality of the welding wire. The uniform coating provided by the advanced technology ensures that the wire is free from defects and inconsistencies. This results in a higher quality product that meets industry standards and customer expectations.

In addition to quality, the high-speed copper-coating line also offers increased durability for the welding wire. The uniform coating helps to protect the wire from corrosion and other environmental factors, extending its lifespan and ensuring that it performs effectively during the welding process.

Overall, the benefits of using a high-speed copper-coating line for CO2 welding wire are clear. From improved efficiency and production capacity to cost savings and enhanced quality, this advanced technology offers a range of advantages for manufacturers. By investing in a high-speed line, companies can streamline their production process, increase output, and deliver a superior product to their customers.

In conclusion, the use of a high-speed copper-coating line for CO2 welding wire is a valuable investment for manufacturers looking to improve their production process. With its ability to provide a consistent and uniform coating, increase production capacity, reduce costs, and enhance quality, this advanced technology offers a range of benefits that can have a significant impact on the overall success of a product. By incorporating a high-speed line into their manufacturing process, companies can stay ahead of the competition and meet the demands of a fast-paced industry.