Table of Contents

Imiba eQhelekileyo kunye neeNgcebiso zoNxibelelwano lweAluminiyam yoHlulo ngocingo loMshini wokuzoba umatshini

Indlela yokuGcina ngokufanelekileyo kunye nokuKhathalela uMshini woMzobo we-Aluminiyam woKuqhekeka kweeNcingo ze-Aluminiyam

Ukuhlola umatshini ukubona iimpawu zokuguga nokonakala ngomnye umba obalulekileyo wolondolozo. Jonga iindawo ezikhululekileyo okanye ezonakeleyo, ezigugileyo ziyafa, kunye nayo nayiphi na eminye imiba enokuchaphazela ukusebenza komatshini. Ukujongana nale miba ngokukhawuleza kunokuthintela umonakalo owongezelelekileyo kunye nokulungiswa kweendleko.

Ukulinganiswa rhoqo komatshini nako kubalulekile ukuqinisekisa ukucuthwa kocingo oluchanekileyo. Ukulinganisa okungafanelekanga kunokubangela ukungahambelani kobunzima bocingo kunye nemiba yomgangatho. Landela izikhokelo zomenzi wolungelelwaniso kwaye wenze uhlengahlengiso njengoko lufuneka ukugcina ukuchaneka komatshini.

Ugcino olululo lomatshini xa ungasetyenziswa luyimfuneko ukunqanda umonakalo kunye nokwandisa ubomi bawo. Gcina umatshini kwindawo ecocekileyo, eyomileyo, nengena umoya kakuhle kude nokufuma kunye namaqondo obushushu agqithisileyo. Gquma umatshini ngetarp okanye ishiti elikhuselayo ukuthintela uthuli kunye nobutyobo ekuqokeleleni kwizinto zalo.

Ukuqeqesha abasebenzi bakho ngendlela efanelekileyo yokusebenza kunye nokugcinwa komatshini wokuzoba umatshini we-aluminiyam wokuqhawula ucingo kubalulekile ukuqinisekisa ukuhlala ixesha elide kunye nokusebenza kakuhle. Ukubonelela ngoqeqesho olubanzi malunga nendlela yokusebenzisa umatshini ngokukhuselekileyo nangempumelelo, kwakunye nendlela yokwenza imisebenzi yesiqhelo yokuwugcina. Khuthaza abasebenzi bakho ukuba baxele nayiphi na imiba okanye izinto ezixhalabisayo ngomatshini ngokukhawuleza.

Ekuqukunjelweni, ukugcinwa okufanelekileyo kunye nokhathalelo lomatshini wokuzoba umatshini wokuqhawula ucingo lwe-aluminiyam kubalulekile ukuqinisekisa ukusebenza kwawo ngokupheleleyo kunye nokuphila ixesha elide. Ukucoca rhoqo, ukuthambisa, ukuhlolwa, ukulinganisa, kunye nokugcinwa kwezinto eziphambili zokugcina umatshini. Ukuqeqesha abasebenzi bakho ngendlela eyiyo yokusebenza nokugcinwa komatshini nako kubalulekile. Ngokulandela ezi zikhokelo, unokwandisa ubomi bomatshini wakho kwaye uqinisekise ukungaguquguquki, ukuveliswa kocingo olukumgangatho ophezulu.

How to Properly Maintain and Care for Aluminum Wire Breakdown Machine Drawing Machine

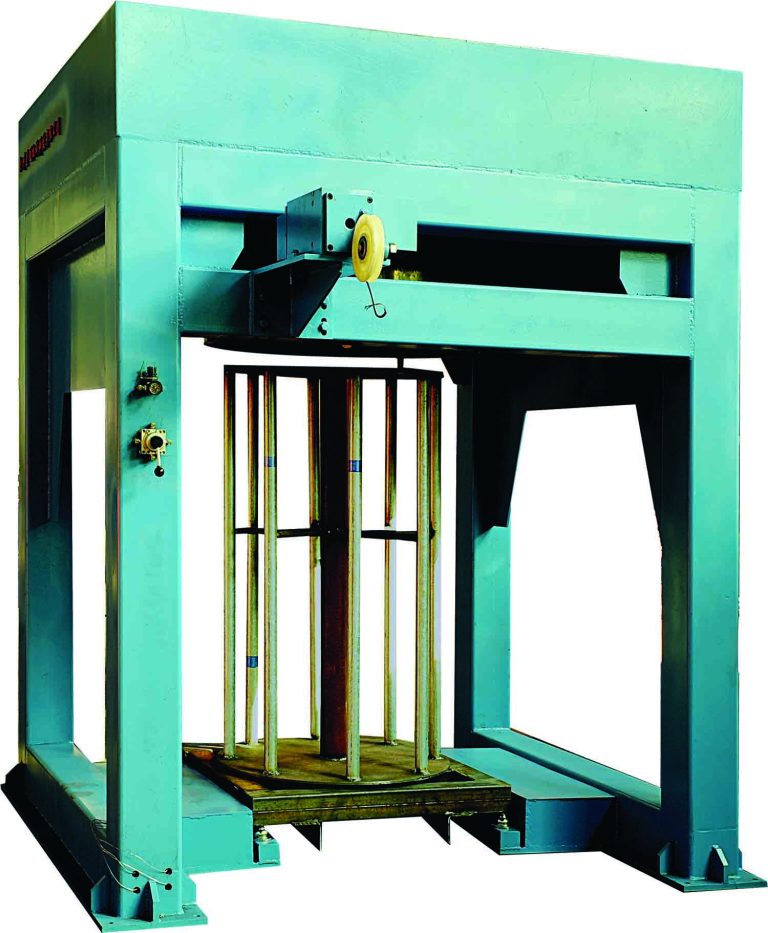

Aluminum wire breakdown machine drawing machines are essential equipment in the wire manufacturing industry. These machines are used to reduce the diameter of aluminum wire by pulling it through a series of dies. Proper maintenance and care of these machines are crucial to ensure their optimal performance and longevity.

One of the most important aspects of maintaining an aluminum wire breakdown machine drawing machine is regular cleaning. Dust, dirt, and debris can accumulate on the machine’s components, leading to decreased efficiency and potential damage. It is recommended to clean the machine after each use to prevent buildup and ensure smooth operation.

In addition to regular cleaning, it is essential to lubricate the machine’s moving parts to reduce friction and wear. Lubrication should be done according to the manufacturer’s recommendations using the appropriate type of lubricant. Over-lubrication can attract dust and debris, while under-lubrication can cause excessive wear on the machine’s components.

Inspecting the machine for signs of wear and damage is another crucial aspect of maintenance. Check for loose or damaged parts, worn-out dies, and any other issues that may affect the machine’s performance. Addressing these issues promptly can prevent further damage and costly repairs.

Regular calibration of the machine is also important to ensure accurate wire diameter reduction. Improper calibration can result in inconsistent wire thickness and quality issues. Follow the manufacturer’s guidelines for calibration and make adjustments as needed to maintain the machine’s accuracy.

Proper storage of the machine when not in use is essential to prevent damage and prolong its lifespan. Store the machine in a clean, dry, and well-ventilated area away from moisture and extreme temperatures. Cover the machine with a protective tarp or sheet to prevent dust and debris from accumulating on its components.

Training your staff on the proper operation and maintenance of the aluminum wire breakdown machine drawing machine is crucial to ensure its longevity and optimal performance. Provide comprehensive training on how to use the machine safely and effectively, as well as how to perform routine maintenance tasks. Encourage your staff to report any issues or concerns with the machine promptly.

In conclusion, proper maintenance and care of an aluminum wire breakdown machine drawing machine are essential to ensure its optimal performance and longevity. Regular cleaning, lubrication, inspection, calibration, and storage are key aspects of maintaining the machine. Training your staff on the proper operation and maintenance of the machine is also crucial. By following these guidelines, you can prolong the lifespan of your machine and ensure consistent, high-quality wire production.