Table of Contents

Izinto eziluncedo zokuSebenzisa umatshini wokuzoba ngocingo olubandayo kwi-Metal Processing

Indlela yokuGcina ngokuchanekileyo kunye nokuQothulwa kweNgxaki kumatshini wokuzoba ngocingo olubandayo

Ukongezelela ekugcinweni rhoqo, kubalulekile ukujongana nayo nayiphi na imiba enokuthi ivele ngomatshini wokudweba ucingo olubandayo. Umba omnye oqhelekileyo onokuthi udibane nabaqhubi kukuqhawula ucingo ngexesha lokuzoba. Oku kunokubangelwa zizinto ezahlukeneyo, ezifana nokulungelelaniswa kweefa okungafanelekanga, ukuxinezeleka okugqithisileyo kucingo, okanye ukufa okugugileyo. Ukusombulula lo mba, abaqhubi kufuneka baqale bajonge ukulungelelaniswa kwee-dies kwaye bahlengahlengise ukuba kukho imfuneko. Kufuneka kwakhona bajonge ukunyanzeliswa kocingo kwaye balungise ukuya kwinqanaba elifanelekileyo. Ukuba iintsizi zigugile, kufuneka zitshintshwe ukuze kuthintelwe ukuqhawuka ngakumbi kocingo. Oku kunokubangelwa kukunxitywa kokufa okungalinganiyo, ukulungelelaniswa kwefa okungafanelekanga, okanye ukutsaleka okungachanekanga kocingo. Ukusombulula lo mba, abaqhubi kufuneka baqale bajonge ukulungelelaniswa kwee-dies kwaye bahlengahlengise ukuba kukho imfuneko. Kufuneka kwakhona bahlole iifayibhile ukuba bakhangele naziphi na iimpawu zokuguga kwaye bazibuyisele xa kukho imfuneko. Ukongeza, abaqhubi kufuneka bajonge ukuxinana kwecingo kwaye bahlengahlengise ukuqinisekisa ukuba i-diameter efanayo.

Ukugcinwa okuchanekileyo kunye nokusombulula ingxaki kumatshini wokuzoba ucingo olubandayo lunokunceda ukukhusela ukuchithwa kweendleko kunye nexesha lokunciphisa. Ngokulandela la macebiso, abaqhubi banokuqinisekisa ukuba umatshini wabo usebenza ngokufanelekileyo nangokufanelekileyo, uvelisa ucingo oluphezulu kwiimfuno zabo zokuvelisa. Ukugcinwa rhoqo, okufana nokuthambisa iindawo ezihambayo kunye nokuhlola ukunxiba, kubalulekile ukuthintela ukusilela kwamalungu kwangaphambi kwexesha. Ukuxazulula iingxaki eziqhelekileyo, ezifana nokuqhawula ucingo kunye nobubanzi bocingo olungalinganiyo, kunokunceda abaqhubi bachonge kwaye basombulule iingxaki ngokukhawuleza ukunciphisa ixesha lokuphumla.

Ekuqukunjelweni, ukugcinwa okufanelekileyo kunye nokucombulula ingxaki yomshini wokudweba ucingo olubandayo kubalulekile ukuqinisekisa ukusebenza kakuhle kunye nokuphila ixesha elide. Ngokulandela la macebiso, abaqhubi banokuthintela ukuchithwa kweendleko kunye nexesha lokunciphisa, kwaye baqinisekise ukuba umatshini wabo uvelisa ucingo oluphezulu kwiimfuno zabo zokuvelisa. Ukugcinwa rhoqo, okufana nokuthambisa amalungu ashukumayo kunye nokuhlola ukunxiba, kubalulekile ukunqanda ukusilela kwamalungu kwangaphambi kwexesha. Ukuxazulula iingxaki eziqhelekileyo, ezifana nokuqhawula ucingo kunye nokungalingani kwe-diameter, kunokunceda abaqhubi bachonge kwaye basombulule iingxaki ngokukhawuleza ukunciphisa ixesha lokunciphisa. Ngokulungiswa okufanelekileyo kunye nokusombulula ingxaki, abaqhubi banokugcina umatshini wabo wokuzoba ngocingo olubandayo usebenza ngokutyibilikayo nangokufanelekileyo kwiminyaka ezayo.

How to Properly Maintain and Troubleshoot Cold Wire Drawing Machine

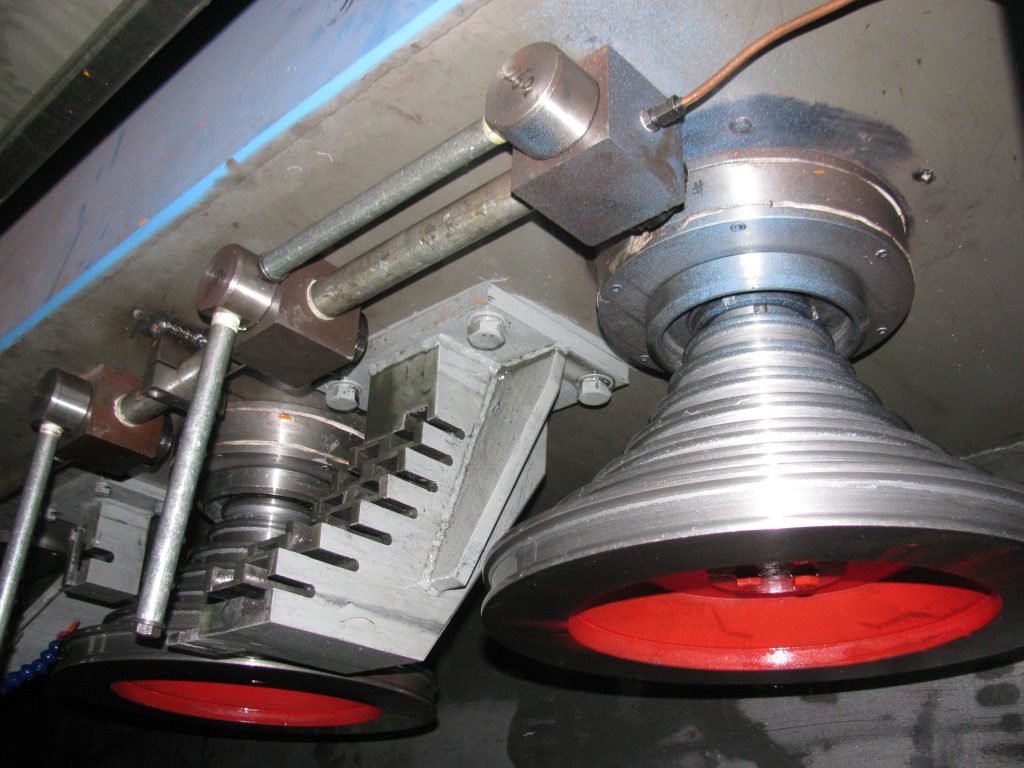

Cold wire drawing machines are essential tools in the manufacturing industry for producing wire of various diameters and lengths. These machines operate by pulling a wire through a series of dies to reduce its diameter, resulting in a smoother and more uniform wire. Proper maintenance and troubleshooting of a cold wire drawing machine are crucial to ensure its optimal performance and longevity.

Regular maintenance of a cold wire drawing machine is essential to prevent breakdowns and ensure smooth operation. One of the most important maintenance tasks is to regularly lubricate the machine’s moving parts to reduce friction and wear. This can help prevent overheating and premature failure of components. It is also important to regularly inspect the machine for any signs of wear or damage, such as worn-out dies or broken parts, and replace them as needed.

In addition to regular maintenance, it is important to troubleshoot any issues that may arise with the cold wire drawing machine. One common issue that operators may encounter is wire breakage during the drawing process. This can be caused by a variety of factors, such as improper die alignment, excessive tension on the wire, or worn-out dies. To troubleshoot this issue, operators should first check the alignment of the dies and adjust them if necessary. They should also check the tension on the wire and adjust it to the proper level. If the dies are worn out, they should be replaced to prevent further wire breakage.

Another common issue with cold wire drawing machines is uneven wire diameter. This can be caused by uneven die wear, improper die alignment, or incorrect tension on the wire. To troubleshoot this issue, operators should first check the alignment of the dies and adjust them if necessary. They should also inspect the dies for any signs of wear and replace them if needed. Additionally, operators should check the tension on the wire and adjust it to ensure a uniform diameter.

Proper maintenance and troubleshooting of a cold wire drawing machine can help prevent costly breakdowns and downtime. By following these tips, operators can ensure that their machine operates smoothly and efficiently, producing high-quality wire for their manufacturing needs. Regular maintenance, such as lubricating moving parts and inspecting for wear, is essential to prevent premature failure of components. Troubleshooting common issues, such as wire breakage and uneven wire diameter, can help operators identify and resolve problems quickly to minimize downtime.

In conclusion, proper maintenance and troubleshooting of a cold wire drawing machine are essential to ensure its optimal performance and longevity. By following these tips, operators can prevent costly breakdowns and downtime, and ensure that their machine produces high-quality wire for their manufacturing needs. Regular maintenance, such as lubricating moving parts and inspecting for wear, is crucial to prevent premature failure of components. Troubleshooting common issues, such as wire breakage and uneven wire diameter, can help operators identify and resolve problems quickly to minimize downtime. With proper maintenance and troubleshooting, operators can keep their cold wire drawing machine running smoothly and efficiently for years to come.