Table of Contents

IiNgcebiso zokuLondoloza koomatshini bokuzoba ooCwangci abaNgqo nkqo

Ukuthelekiswa kweeModeli ezahlukeneyo zoomatshini abaNxibelela abaNxibeleyo bokuzoba oomatshini

Umatshini wokuzoba umzobo othe nkqo kwibhloko enye zizixhobo ezibalulekileyo kushishino lokuvelisa ucingo. Aba matshini basetyenziselwa ukutsala ucingo ngothotho lweefa ukuze kuncitshiswe ubukhulu balo kunye nokuphucula umgangatho walo. Kukho iimodeli ezininzi zoomatshini bokuzoba ngocingo oluthe nkqo olukhoyo kwimarike, nganye ineempawu zayo ezizodwa kunye nesakhono. Kweli nqaku, siza kuthelekisa iimodeli ezahlukeneyo zoomatshini bokuzoba ngocingo oluthe nkqo ukukunceda wenze isigqibo esinolwazi xa ukhetha umatshini ochanekileyo kwiimfuno zakho zokuzoba ngocingo.

Ekuqukumbeleni, oomatshini bokuzoba becingo oluthe nkqo zizixhobo ezibalulekileyo kushishino lokwenziwa kweengcingo. Ngokuthelekisa iimodeli ezahlukeneyo ngokusekwe kwizinto ezinje ngenani lokufa, isantya sokuzoba, umgangatho wokwakha, kunye neempawu ezizenzekelayo, unokukhetha umatshini ohlangabezana neemfuno zakho zemveliso kwaye kukunceda ukuba ufezekise ukusebenza ngokufanelekileyo nangokuthembekileyo komzobo wocingo.

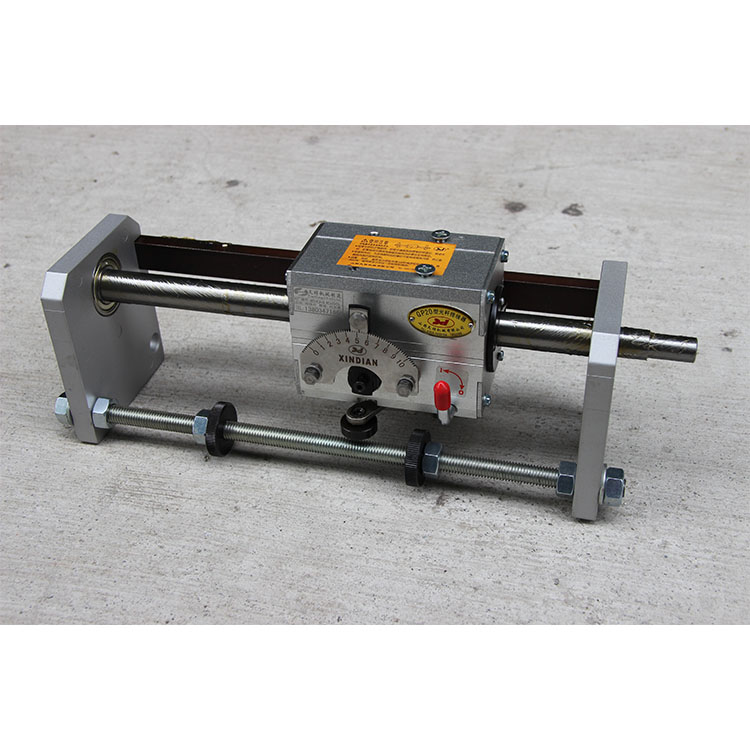

Inverted Vertical Single Block Wire Drawing Machine are essential equipment in the wire manufacturing industry. These machines are used to draw wire through a series of dies to reduce its diameter and improve its quality. There are several models of inverted vertical wire drawing machines available on the market, each with its own unique features and capabilities. In this article, we will compare different models of inverted vertical wire drawing machines to help you make an informed decision when choosing the right machine for your wire drawing needs.

One of the key factors to consider when comparing different models of inverted vertical wire drawing machines is the number of dies that the machine can accommodate. Machines with a higher number of dies are capable of drawing wire to a smaller diameter in a single pass, which can improve efficiency and reduce production time. However, machines with fewer dies may be more suitable for drawing thicker wire or for applications where a high level of precision is required.

Another important factor to consider is the speed at which the machine can draw wire. Machines with a higher drawing speed can increase productivity and reduce production costs. However, it is important to balance speed with quality, as drawing wire too quickly can result in a lower quality end product. Some models of inverted vertical wire drawing machines are equipped with variable speed controls, allowing operators to adjust the drawing speed to meet specific production requirements.

In addition to the number of dies and drawing speed, it is also important to consider the overall design and construction of the machine. Machines with a sturdy and durable construction are more likely to withstand the rigors of continuous use and provide reliable performance over time. Look for machines that are made from high-quality materials and feature precision engineering to ensure consistent and accurate wire drawing.

When comparing different models of inverted vertical wire drawing machines, it is also important to consider the level of automation and control features available. Machines with advanced automation features, such as programmable logic controllers (PLCs) and touch screen interfaces, can improve efficiency and reduce the risk of human error. Additionally, machines with built-in safety features, such as emergency stop buttons and overload protection, can help to ensure a safe working environment for operators.

Ultimately, the best model of inverted vertical wire drawing machine for your needs will depend on a variety of factors, including the type of wire you are drawing, the desired diameter of the end product, and your production requirements. By carefully considering the number of dies, drawing speed, construction quality, and automation features of different models, you can choose a machine that meets your specific requirements and helps you achieve your production goals.

In conclusion, inverted vertical wire drawing machines are essential equipment for the wire manufacturing industry. By comparing different models based on factors such as the number of dies, drawing speed, construction quality, and automation features, you can choose a machine that meets your specific production requirements and helps you achieve efficient and reliable wire drawing operations.