Table of Contents

Indlela yokukhetha umatshini wokuzoba weCopper oLungileyo kunye ne-Annealer kwiimfuno zakho

Iingcebiso zoLondolozo zokuqinisekisa uBomi obude bomatshini wakho wokuzoba wocingo lweCopper kunye ne-Annealer

Enye ingcebiso engundoqo yokulungisa umatshini wakho wokuzoba ngocingo lobhedu onomshini wokuthunga amanzi kukuhlola amalungu omatshini rhoqo ukubona iimpawu zokuguga okanye ukonakala. Jonga umzobo wocingo uyafa, iirola, kunye neziko lokutshisa ukuba kukho iintanda, izibonda, okanye ezinye iziphene ezinokuchaphazela ukusebenza komatshini. Faka endaweni yazo naziphi na iindawo ezigugileyo okanye ezonakeleyo ngoko nangoko ukuze uthintele umonakalo ongakumbi kumatshini.

Ngaphezu kokucoca nokuhlola rhoqo, kubalulekile ukulungelelanisa umatshini wakho wokuzoba ngocingo lobhedu nge-annealer rhoqo. Ukulinganisa kuqinisekisa ukuba umatshini usebenza ngokufanelekileyo kwaye uvelisa ucingo oluphezulu. Qhagamshelana nezikhokelo zomenzi malunga neshedyuli ecetyiswayo yolungelelwaniso kwaye uyilandele ngenkuthalo ukugcina ukusebenza komatshini.

Ugcino olululo lomatshini wakho wokuzoba ngocingo lobhedu olunomatshini wokuhambisa i-anneal nalo lubalulekile ekuqinisekiseni ukuba luhlala ixesha elide. Gcina umatshini kwindawo ecocekileyo, eyomileyo, nengena umoya ukuze uthintele umhlwa kunye nomhlwa. Gquma umatshini ngethaphu yokukhusela okanye ishidi xa ungasetyenziswanga ukuwukhusela eluthulini nakumanzi. Ukongezelela, qwalasela ukutyala imali kwi-dehumidifier ukugcina umgangatho ofanelekileyo wokufuma kwindawo yokugcina.

Ukugcinwa rhoqo komatshini wakho wokudweba ucingo lobhedu kunye ne-annealer akugcini nje ukwandisa ixesha lokuphila kodwa kuqinisekisa ukuveliswa kocingo olungaguqukiyo kunye nomgangatho ophezulu. Ngokulandela ezi ngcebiso zokulondoloza, unokugcina umatshini wakho ukwimeko ephezulu kwaye ugweme ukulungiswa kweendleko okanye ukutshintshwa.

Ekuqukunjelweni, ukulungiswa okufanelekileyo ngundoqo ekuqinisekiseni ixesha elide lomatshini wakho wokudweba ucingo lobhedu kunye ne-annealer. Ukucoca rhoqo, ukuhlolwa, ukulinganisa, kunye nokugcinwa yimisebenzi ebalulekileyo yokulondoloza ekufuneka yenziwe ngenkuthalo. Ngokukhathalela umatshini wakho, unokwandisa ixesha lokuphila kunye nemveliso, ekugqibeleni uzuze imisebenzi yakho yokuvelisa ucingo.

Maintenance Tips for Ensuring Longevity of Your Copper Wire Drawing Machine With Annealer

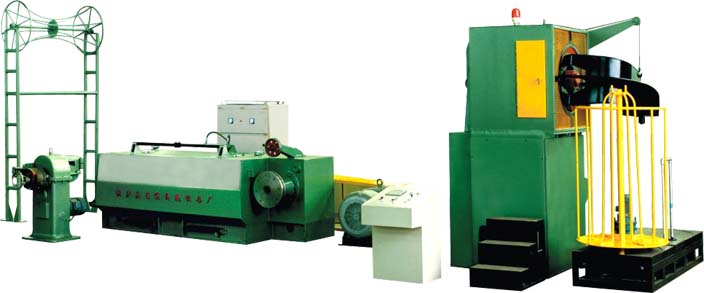

Copper wire drawing machines with annealers are essential equipment in the wire manufacturing industry. These machines are used to draw copper wire to the desired diameter and anneal it to improve its ductility and conductivity. To ensure the longevity of your copper wire drawing machine with annealer, proper maintenance is crucial.

One of the most important maintenance tasks for your copper Wet Type Wire Drawing Machine with annealer is regular cleaning. Dust, dirt, and debris can accumulate on the machine’s components, leading to increased wear and tear. It is recommended to clean the machine regularly using a soft brush or cloth to remove any buildup. Additionally, lubricating the moving parts of the machine with a suitable lubricant can help reduce friction and prevent premature wear.

Another key maintenance tip for your copper wire drawing machine with annealer is to inspect the machine’s components regularly for signs of wear or damage. Check the wire drawing dies, rollers, and annealing furnace for any cracks, dents, or other defects that may affect the machine’s performance. Replace any worn or damaged parts immediately to prevent further damage to the machine.

In addition to regular cleaning and inspection, it is important to calibrate your copper wire drawing machine with annealer regularly. Calibration ensures that the machine is operating at optimal efficiency and producing high-quality wire. Consult the manufacturer’s guidelines for the recommended calibration schedule and follow it diligently to maintain the machine’s performance.

Proper storage of your copper wire drawing machine with annealer is also essential for ensuring its longevity. Store the machine in a clean, dry, and well-ventilated area to prevent rust and corrosion. Cover the machine with a protective tarp or sheet when not in use to shield it from dust and moisture. Additionally, consider investing in a dehumidifier to maintain the ideal humidity level in the storage area.

Regular maintenance of your copper wire drawing machine with annealer not only prolongs its lifespan but also ensures consistent and high-quality wire production. By following these maintenance tips, you can keep your machine in top condition and avoid costly repairs or replacements.

In conclusion, proper maintenance is key to ensuring the longevity of your copper wire drawing machine with annealer. Regular cleaning, inspection, calibration, and storage are essential maintenance tasks that should be performed diligently. By taking care of your machine, you can maximize its lifespan and productivity, ultimately benefiting your wire manufacturing operations.