Table of Contents

Izinto eziluncedo zokuSebenzisa iiNkqubo zeNtlawulo ezithe nkqo koomatshini bokuzoba ngocingo

Indlela Iinkqubo zokuHlawula ngokuNgqongileyo ziPhucula iNdlela yokuSebenza kunye neMveliso kwiMisebenzi yokuDla iiNcingo

Enye inzuzo yeesistim zokuhlawula ngokuthe nkqo kukukwazi kwazo ukufaka iispools ezinkulu zocingo. Ngee-spools ezibekwe ngokuthe nkqo, akukho mda kubungakanani be-spool enokuthi isetyenziswe, ivumela ukuqhuba imveliso ixesha elide kunye nokuphazamiseka okumbalwa kweenguqu ze-spool. Oku kunenzuzo ngokukodwa kwimisebenzi yokuzoba ngocingo oluphezulu, apho ukwandisa ixesha lokuphumla kubalulekile ekuhlangabezaneni nokujoliswe kuko kwemveliso.

Ngokukwazi ukulungelelanisa ngokulula ukuphakama kwee-spools zocingo, abaqhubi banokwenza ngokwezifiso i-angle yokutya ukuze ihambelane neemfuno ezithile zenkqubo yokudweba ucingo. Lo mgangatho wokwenza ngokwezifiso unokunceda ukukhulisa inkqubo yokuzoba, okukhokelela kwiimveliso zocingo ezikumgangatho ophezulu.

Ikonke, iinkqubo zokuhlawula ngokuthe nkqo zimela ukuqhubela phambili okubonakalayo kubuchwepheshe bokuzoba ngocingo, ukunika uluhlu lweenzuzo ezinokuphucula ukusebenza kakuhle kunye nemveliso kumzobo wocingo. imisebenzi. Ukusuka kugcino lwendawo kunye nokufikeleleka okuphuculweyo ukuya kwimpumelelo eyongeziweyo kunye nokuguquguquka, ezi nkqubo zibonelela ngesisombululo esinyanzelisayo kubavelisi abafuna ukukhulisa iinkqubo zabo zokuzoba ngocingo. Njengoko ishishini liqhubeka nokuvela, iinkqubo zokuhlawula ngokuthe nkqo zinokuba lukhetho oluqhelekileyo lwemisebenzi yokuzoba ngocingo efuna ukwandisa imveliso kunye nokunciphisa ixesha lokuphumla.

How Vertical Pay-off Systems Improve Efficiency and Productivity in Wire Drawing Operations

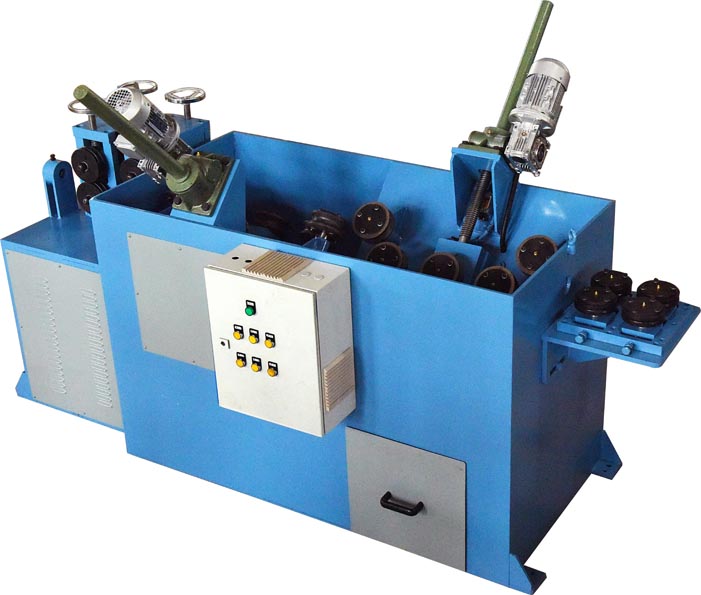

Wire drawing is a process used in various industries to reduce the diameter of wire by pulling it through a series of dies. This process is essential for producing wire of different sizes and shapes, which are used in a wide range of applications, from construction to electronics. One critical component of the wire drawing process is the Overhead Payoff system, which feeds the wire into the drawing machine.

Traditionally, pay-off systems have been designed with a horizontal orientation, where the wire spools are placed on a horizontal axis. However, in recent years, there has been a shift towards vertical pay-off systems, which offer several advantages over their horizontal counterparts.

One of the primary benefits of vertical pay-off systems is their space-saving design. By orienting the wire spools vertically, these systems take up less floor space compared to horizontal pay-off systems. This is particularly advantageous in facilities where space is limited, allowing for more efficient use of the available area.

In addition to space savings, vertical pay-off systems also offer improved accessibility. With the wire spools positioned vertically, operators can easily access and change out spools without having to navigate around a horizontal axis. This not only saves time but also reduces the risk of injury by minimizing the need for awkward bending and reaching.

Furthermore, vertical pay-off systems can enhance the overall efficiency of wire drawing operations. By eliminating the need for complex wire guiding mechanisms, these systems simplify the wire feeding process, reducing the likelihood of jams and other issues that can disrupt production. This results in smoother operation and higher productivity, ultimately leading to cost savings for the manufacturer.

Another advantage of vertical pay-off systems is their ability to accommodate larger wire spools. With the spools positioned vertically, there is no limit to the size of spool that can be used, allowing for longer production runs and fewer interruptions for spool changes. This is particularly beneficial for high-volume wire drawing operations, where maximizing uptime is crucial for meeting production targets.

Additionally, vertical pay-off systems offer greater flexibility in terms of wire handling. With the ability to easily adjust the height of the wire spools, operators can customize the feeding angle to suit the specific requirements of the wire drawing process. This level of customization can help optimize the drawing process, resulting in higher quality wire products.

Overall, vertical pay-off systems represent a significant advancement in wire drawing technology, offering a range of benefits that can improve efficiency and productivity in wire drawing operations. From space savings and improved accessibility to enhanced efficiency and flexibility, these systems provide a compelling solution for manufacturers looking to optimize their wire drawing processes. As the industry continues to evolve, vertical pay-off systems are likely to become the standard choice for wire drawing operations seeking to maximize their output and minimize downtime.