Table of Contents

Ukuphucula ukusebenza kakuhle kunye noMgangatho nge-Speed High Speed Copper-Coating Line ye-CO2 Welding Wire

Ngaphezu koko, umgca we-copper high-speed copper unokuphucula ukhuseleko lwasemsebenzini. Ngokuzenzekelayo inkqubo yokugquma, abavelisi banokunciphisa umngcipheko weengozi kunye nokulimala okuhambelana neendlela zokugqoka ngesandla. Oku akukhuseli kuphela abasebenzi ebungozini kodwa kunciphisa ixesha lokuphumla kunye nokulahleka kwemveliso ngenxa yeziganeko zasemsebenzini. Ngokudala indawo ekhuselekileyo yokusebenza, abavelisi banokuphucula ukuziphatha kwabasebenzi kunye nokugcinwa, okukhokelela kubasebenzi abavelisayo kunye nabasebenzayo.

Kuko konke, ukutyalomali kumgca wokugubungela ubhedu olukhawulezayo kwimveliso ye-CO2 welding wire unokuba nefuthe elibalulekileyo kumenzi. ukusebenza kakuhle kunye nomgangatho. Ngokunyusa isantya semveliso, ukuphucula umgangatho wemveliso, ukunciphisa iindleko, kunye nokuphucula ukhuseleko kwindawo yokusebenza, abavelisi banokufezekisa iinjongo zabo zokuvelisa kwaye bahlale bekhuphisana kwimarike. Ngezixhobo ezifanelekileyo kunye neenkqubo ezikhoyo, abavelisi banokuhlengahlengisa imisebenzi yabo kwaye banikeze iimveliso ezikumgangatho ophezulu kubathengi babo rhoqo. Ukuqukumbela, umgca we-copper wesantya esiphezulu utyalo-mali oluxabisekileyo kunoma yimuphi umenzi ojonge ukuphucula ukusebenza kunye nomgangatho kwimveliso ye-CO2 ye-welding wire.

Iinzuzo zokuSebenzisa i-Speed Speed Copper Coating Line ye-CO2 Welding Wire

Ngaphezu koko, umgca we-copper-speed high-speed copper unokuphucula ukuqina kunye nokuphila ixesha elide kwi-welding wire. Ingubo yobhedu isebenza njengesithintelo sokukhusela, ukuthintela ukubola kunye nokwandisa ixesha lokuphila kocingo. Oku kubaluleke kakhulu kwizicelo ze-welding kwiindawo ezinzima okanye iimeko zokushisa okuphezulu, apho ucingo lubonakaliswe kwiimeko ezinzima.

Ekuqukunjelweni, iinzuzo zokusebenzisa umgca we-copper we-high-speed copper we-CO2 welding wire icacile. Ukusuka kwisantya esongeziweyo semveliso kunye nokusebenza kakuhle ukuya ekuphuculweni komgangatho wemveliso kunye neenketho zokwenza ngokwezifiso, obu buchwephesha obuphezulu bubonelela ngeenzuzo ezininzi kubavelisi kwishishini le-welding. Ngokwenza utyalo-mali kumgca wokugquma wobhedu onesantya esiphezulu, abavelisi banokwandisa amandla abo okuvelisa, banciphise iindleko, kwaye banikezele ngocingo olukwizinga eliphezulu lokuwelda oluhlangabezana neemfuno zemarike yanamhlanje ekhuphisanayo.

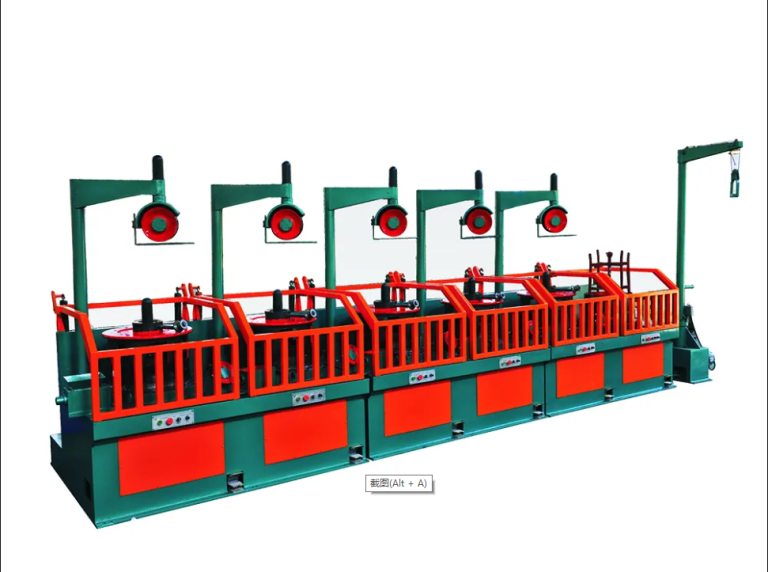

A High Speed Copper-Coating Line For CO2 Welding Wire offers numerous benefits for manufacturers in the welding industry. This advanced technology allows for faster and more efficient production of welding wire, resulting in cost savings and improved product quality.

One of the key advantages of using a high-speed copper coating line is the increased production speed. By automating the process of applying copper coating to the welding wire, manufacturers can significantly reduce the time it takes to produce a batch of wire. This not only allows for higher output levels but also enables manufacturers to meet tight production deadlines and customer demands.

In addition to speed, a high-speed copper coating line also ensures consistent and uniform coating thickness on the welding wire. This is crucial for ensuring the quality and performance of the wire in welding applications. By eliminating variations in coating thickness, manufacturers can produce high-quality welding wire that meets industry standards and customer expectations.

Furthermore, the use of a high-speed copper coating line can help reduce material waste and improve overall efficiency in the production process. By precisely controlling the amount of copper coating applied to the wire, manufacturers can minimize excess material usage and reduce costs. This not only benefits the bottom line but also contributes to a more sustainable and environmentally friendly manufacturing process.

Another advantage of using a high-speed copper coating line is the ability to customize the coating thickness and composition to meet specific requirements. This flexibility allows manufacturers to produce welding wire that is tailored to the needs of different applications and industries. Whether it’s for automotive, construction, or industrial welding, manufacturers can adjust the coating parameters to achieve the desired performance characteristics.

Moreover, a high-speed copper coating line can improve the overall durability and longevity of the welding wire. The copper coating acts as a protective barrier, preventing corrosion and extending the lifespan of the wire. This is particularly important for welding applications in harsh environments or high-temperature conditions, where the wire is exposed to extreme conditions.

In conclusion, the benefits of using a high-speed copper coating line for CO2 welding wire are clear. From increased production speed and efficiency to improved product quality and customization options, this advanced technology offers numerous advantages for manufacturers in the welding industry. By investing in a high-speed copper coating line, manufacturers can enhance their production capabilities, reduce costs, and deliver high-quality welding wire that meets the demands of today’s competitive market.