Table of Contents

Iingcebiso eziPhakamileyo zokuGcina ngokufanelekileyo kunye nokusebenzisa i-Steel Brush Descaler

IiNzuzo zokuSebenzisa i-Steel Brush Descaler kuLondolozo lweziXhobo zeShishini

Indlela yokukhetha i-Eright Steel Brush Descaler kwiimfuno zakho

Enye yezinto zokuqala ekufuneka ziqwalaselwe xa ukhetha i-descaler yebrashi yensimbi ubukhulu kunye namandla omatshini. Iidesika zebrashi yentsimbi ziza ngobukhulu obahlukeneyo, ukusuka kwiimodeli ezincinci eziphathwa ngesandla ukuya koomatshini abakhulu bemizi-mveliso. Ubungakanani bomatshini owukhethayo buya kuxhomekeka kubungakanani bemigangatho oyifunayo ukuyicoca kunye nomthamo wamandla owufunayo ukususa i-debris ngokufanelekileyo. Kwimisebenzi emincinci, i-handheld okanye i-portable steel brush descaler inokwanela, ngelixa izicelo ezinkulu zemizi-mveliso zinokufuna umatshini omkhulu, onamandla ngakumbi.

Enye into ebalulekileyo ekufuneka uyiqwalasele xa ukhetha i-brashi yentsimbi ye-descaler luhlobo lweebhrashi oluzisebenzisayo. Iibrashi zeebrashi zentsimbi ziza neentlobo ngeentlobo zebrashi, kubandakanywa iibrashi zocingo, iibrashi zenayiloni, kunye neebrashi ezirhabaxa. Uhlobo lwebrashi oyikhethayo luya kuxhomekeka kuhlobo lomphezulu owufunayo ukuba uhlambuluke kunye nezinga lokuqina elifunekayo. Iibhrashi zocingo zilungele ukususa umhlwa onzima kunye nesikali kumphezulu wesinyithi, ngelixa iibhrashi zenayiloni zithambile kwaye zifanele umphezulu oethe-ethe ngakumbi. Iibrashi eziqhotsayo zezona zinamandla kwaye zilungele ukususa inkunkuma eyomeleleyo kumphezulu wentsimbi.

Ukongeza kubungakanani kunye nodidi lwebrashi, kubalulekile kwakhona ukuqwalasela isantya kunye namandla esixhobo sokususa ibrashi yentsimbi. Isantya somatshini siya kugqiba ukuba unokucoca ngokukhawuleza kangakanani umphezulu, ngelixa amandla aya kugqiba ukuba unokususa njani inkunkuma. Izantya eziphezulu kunye nemigangatho yamandla ngokuqhelekileyo ingcono kwinkunkuma enkulu, enenkani ngakumbi, ngelixa isantya esisezantsi kunye namanqanaba ombane afanelekile kwi-debris encinci, engaphantsi kwenkani. Kubalulekile ukukhetha umatshini onomlinganiselo ochanekileyo wesantya kunye namandla kwiimfuno zakho ezithile zokuqinisekisa ukucoca ngokufanelekileyo nangokufanelekileyo.

Xa ukhetha i-descaler yebrashi yensimbi, kubalulekile ukuqwalasela ukuqina kunye nokuthembeka komatshini. Khangela umatshini owenziwe kwizinto eziphezulu ezinokumelana nokusetyenziswa kanzima kunye nokubonelela ngokusebenza okuhambelanayo ngexesha. Ikwangumbono olungileyo ukukhetha umatshini kumvelisi othembekileyo onerekhodi yokuvelisa iimveliso ezithembekileyo, ezikumgangatho ophezulu. Ukufunda ukuphononongwa kunye nobungqina obuvela kwabanye abathengi nabo banokukunceda ukuba ubone ukuqina kunye nokuthembeka komatshini othile. Cinga izinto ezifana nobukhulu, uhlobo lwebrashi, isantya, amandla, ukuqina, kunye nokuthembeka xa ukhetha umatshini wokuqinisekisa ukuba ufumana iziphumo ezilungileyo kwiimfuno zakho ezithile. Ngokuthatha ixesha lokuphanda kwaye uthelekise iinketho ezahlukeneyo, ungafumana isixhobo sokususa ibrashi yentsimbi ehlangabezana neemfuno zakho kwaye sikuncede ufezekise imigangatho yentsimbi ecocekileyo, engenankunkuma.

Benefits of Using Steel Brush Descaler for Industrial Equipment Maintenance

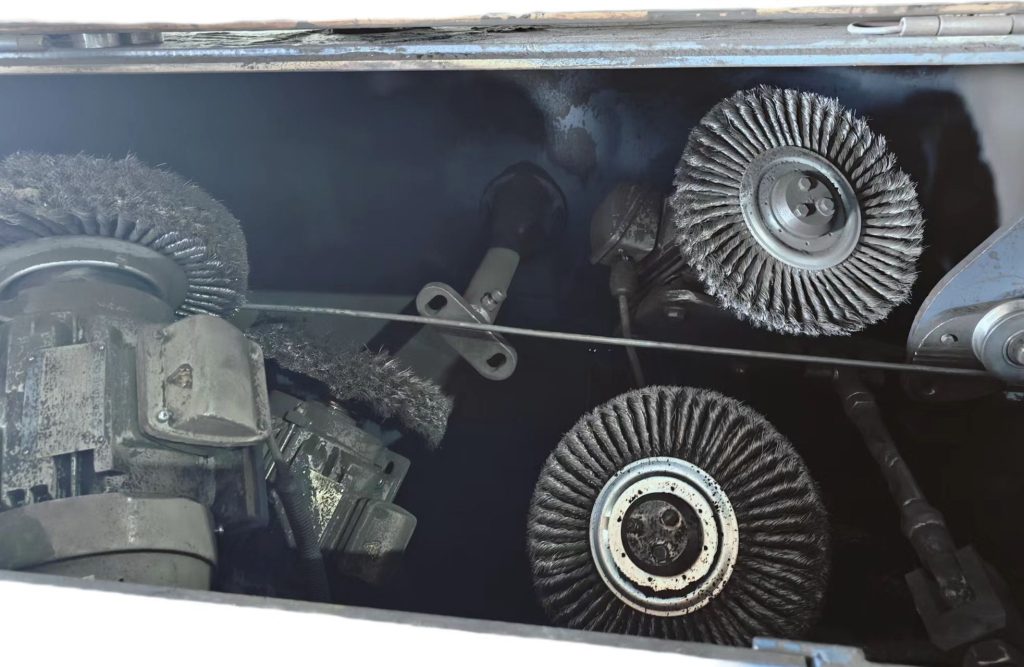

Steel brush descalers are essential tools for maintaining industrial equipment and machinery. These powerful tools are designed to remove rust, scale, and other debris from metal surfaces, ensuring that equipment operates efficiently and safely. In this article, we will explore the benefits of using a steel brush descaler for industrial equipment maintenance.

One of the primary benefits of using a steel brush descaler is its ability to effectively remove rust and scale from metal surfaces. Over time, metal equipment can become corroded and degraded due to exposure to moisture and other environmental factors. Rust and scale can weaken metal structures, leading to equipment failure and safety hazards. By using a steel brush descaler, you can easily remove these corrosive materials and restore metal surfaces to their original condition.

In addition to removing rust and scale,Mechanical Wire Descaler for wire drawing process are also effective at cleaning metal surfaces. Dirt, grease, and other contaminants can build up on industrial equipment, affecting its performance and longevity. A steel brush descaler can quickly and efficiently remove these contaminants, leaving metal surfaces clean and ready for use. This not only improves the appearance of equipment but also helps to prevent corrosion and other damage.

Another benefit of using a steel brush descaler is its versatility. These tools come in a variety of sizes and configurations, making them suitable for a wide range of industrial applications. Whether you need to clean large machinery or small components, there is a steel brush descaler that is right for the job. Additionally, steel brush descalers can be used on a variety of metal surfaces, including steel, aluminum, and copper, making them a versatile tool for industrial maintenance.

Using a steel brush descaler is also a cost-effective way to maintain industrial equipment. Regular maintenance and cleaning can help to extend the life of machinery, reducing the need for costly repairs or replacements. By investing in a steel brush descaler, you can keep your equipment in top condition and avoid the expenses associated with neglecting maintenance.

Furthermore, using a steel brush descaler is a safe and environmentally friendly way to clean metal surfaces. Unlike harsh chemicals and abrasive materials, steel brush descalers do not produce harmful fumes or residues that can be harmful to workers or the environment. This makes them a preferred choice for industrial maintenance professionals who are committed to safety and sustainability.

In conclusion, steel brush descalers are essential tools for maintaining industrial equipment and machinery. These versatile tools are effective at removing rust, scale, and other contaminants from metal surfaces, improving equipment performance and longevity. By investing in a steel brush descaler, you can keep your industrial equipment in top condition, reduce maintenance costs, and promote a safe and environmentally friendly work environment.

How to Choose the Right Steel Brush Descaler for Your Needs

When it comes to removing rust, scale, and other debris from metal surfaces, a Mechanical brush descaler is an essential tool. These powerful machines use abrasive brushes to quickly and efficiently clean metal surfaces, making them ideal for a wide range of applications, from industrial cleaning to automotive restoration. If you’re in the market for a steel brush descaler, there are a few key factors to consider to ensure you choose the right machine for your needs.

One of the first things to consider when choosing a steel brush descaler is the size and power of the machine. Steel brush descalers come in a variety of sizes, from small handheld models to large industrial machines. The size of the machine you choose will depend on the size of the surfaces you need to clean and the amount of power you need to remove debris effectively. For smaller jobs, a handheld or portable steel brush descaler may be sufficient, while larger industrial applications may require a larger, more powerful machine.

Another important factor to consider when choosing a steel brush descaler is the type of brushes it uses. Steel brush descalers come with a variety of brush types, including wire brushes, nylon brushes, and abrasive brushes. The type of brush you choose will depend on the type of surface you need to clean and the level of abrasiveness required. Wire brushes are ideal for removing heavy rust and scale from metal surfaces, while nylon brushes are gentler and are suitable for more delicate surfaces. Abrasive brushes are the most powerful option and are ideal for removing tough debris from metal surfaces.

In addition to size and brush type, it’s also important to consider the speed and power of the steel brush descaler. The speed of the machine will determine how quickly it can clean a surface, while the power will determine how effectively it can remove debris. Higher speeds and power levels are generally better for larger, more stubborn debris, while lower speeds and power levels are suitable for smaller, less stubborn debris. It’s important to choose a machine with the right balance of speed and power for your specific needs to ensure efficient and effective cleaning.

When choosing a steel brush descaler, it’s also important to consider the durability and reliability of the machine. Look for a machine made from high-quality materials that can withstand heavy use and provide consistent performance over time. It’s also a good idea to choose a machine from a reputable manufacturer with a track record of producing reliable, high-quality products. Reading reviews and testimonials from other customers can also help you determine the durability and reliability of a particular machine.

In conclusion, choosing the right steel brush descaler is essential for effective metal surface cleaning. Consider factors such as size, brush type, speed, power, durability, and reliability when choosing a machine to ensure you get the best results for your specific needs. By taking the time to research and compare different options, you can find a steel brush descaler that meets your requirements and helps you achieve clean, debris-free metal surfaces.