Ukubaluleka kweZixhobo eziNcedisayo kwiNkqubo yokuzoba ngocingo

Enye yezona zinto zibalulekileyo zezixhobo ezincedisayo kwi-wire drawing yi-wire straightener. Njengoko ucingo lutsalwa ngokufa, lunokugotywa okanye lujijeke, olunokuchaphazela umgangatho wemveliso yokugqibela. I-wire straightener isetyenziselwa ukususa nayiphi na i-bends okanye i-twist kwi-wire, iqinisekisa ukuba ihlala ithe tye kwaye ifana nayo yonke inkqubo yokudweba. Oku akuphuculi kuphela umgangatho wocingo kodwa kunceda ukuthintela umonakalo kwi-dies and other equipment.

Elinye iqhekeza elibalulekileyo lentsimbi yokususa ibrashi yokususa inkqubo yokuzoba yinkqubo yokuthambisa. Njengoko ucingo lutsalwa kwindawo yokufa, ukukhuhlana kunokwakheka, kubangele ubushushu kwaye kuguge kuzo zombini ucingo kwaye lufe. Inkqubo yokuthambisa isetyenziselwa ukunciphisa ukukhuhlana kunye nobushushu, ukuvumela ucingo ukuba luhambe kakuhle ngokufa kunye nokunciphisa ukuguga kwezixhobo. Oku akuphuculi nje ukusebenza kakuhle kwenkqubo yokuzoba kodwa kunceda ekwandiseni ubomi bokufa kunye namanye amacandelo.

Ukongeza kwiinkqubo zokulungisa ucingo kunye neenkqubo zokuthambisa, kukho ezinye iindidi zezixhobo ezincedisayo ezisetyenziswa ngokuqhelekileyo ekuzobeni ucingo. . Ezi zibandakanya i-spoolers, ezisetyenziselwa ukujikelezisa ucingo olutsalweyo kwi-spools yokugcina kunye nokuthutha, kunye neenkqubo zokulawula ukuxinana, ezinceda ukugcina ukuxinana okungaguqukiyo kucingo njengoko lutsalwa kwiifa. Ezi ziqwenga zezixhobo ezincedisayo zisebenza kunye ukuze kuqinisekiswe ukuba inkqubo yokudweba ucingo ihamba kakuhle kwaye isebenze kakuhle, ivelisa iimveliso zocingo eziphezulu.

Ukubaluleka kwezixhobo ezincedisayo kwinkqubo yokudweba ucingo ayikwazi ukugqithiswa. Ngaphandle kwezi ziqwenga zibalulekileyo zezixhobo, umgangatho weemveliso zocingo eziveliswayo uya kuthotywa, kwaye ukusebenza kakuhle kwenkqubo kuya kuncitshiswa kakhulu. Ngokutyala imali kwizixhobo ezincedisayo ezikumgangatho ophezulu kunye nokuqinisekisa ukuba zigcinwe ngokufanelekileyo kwaye zisebenza, abavelisi banokuphucula umgangatho weemveliso zabo zocingo, ukunciphisa ixesha lokunciphisa kunye neendleko zokugcina, kunye nokwandisa imveliso yonke.

Ekuqukumbeleni, izixhobo ezincedisayo zidlala indima ebalulekileyo. kwinkqubo yokudweba ucingo, inceda ukuqinisekisa ukusebenza kakuhle kunye nomgangatho wemveliso yokugqibela. Iingcingo zoluleko, iinkqubo zokuthambisa, izitshixo, kunye neenkqubo zokulawula ukuxinezeleka yimizekelo nje embalwa yezixhobo ezincedisayo ezisetyenziswayo ekuzobeni ucingo. Ngokwenza utyalo-mali kwizixhobo ezincedisayo ezikumgangatho ophezulu kunye nokuqinisekisa ukuba zigcinwa kwaye zisebenza ngokufanelekileyo, abavelisi banokuwuphucula umgangatho weemveliso zabo zocingo, banciphise ixesha lokuphumla kunye neendleko zokuyigcina, kwaye bandise imveliso ngokubanzi.

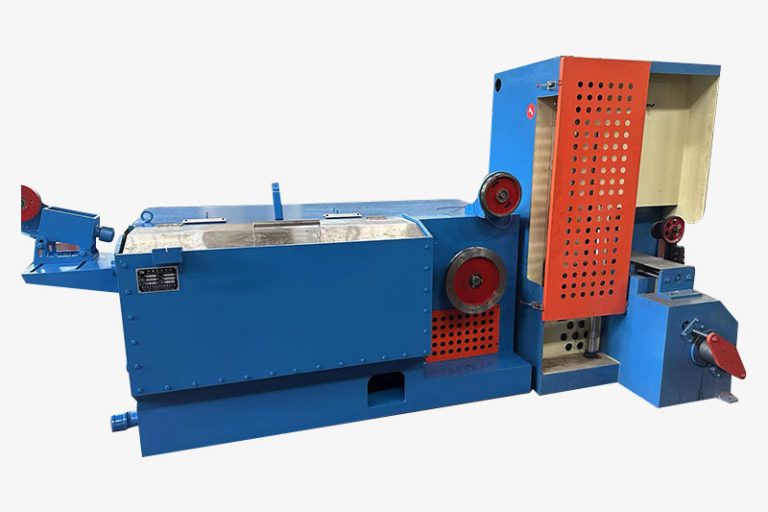

One of the most important pieces of auxiliary equipment in wire drawing is the wire straightener. As the wire is pulled through the dies, it can become bent or twisted, which can affect the quality of the final product. The wire straightener is used to remove any bends or twists in the wire, ensuring that it remains straight and uniform throughout the drawing process. This not only improves the quality of the wire but also helps to prevent damage to the dies and other equipment.

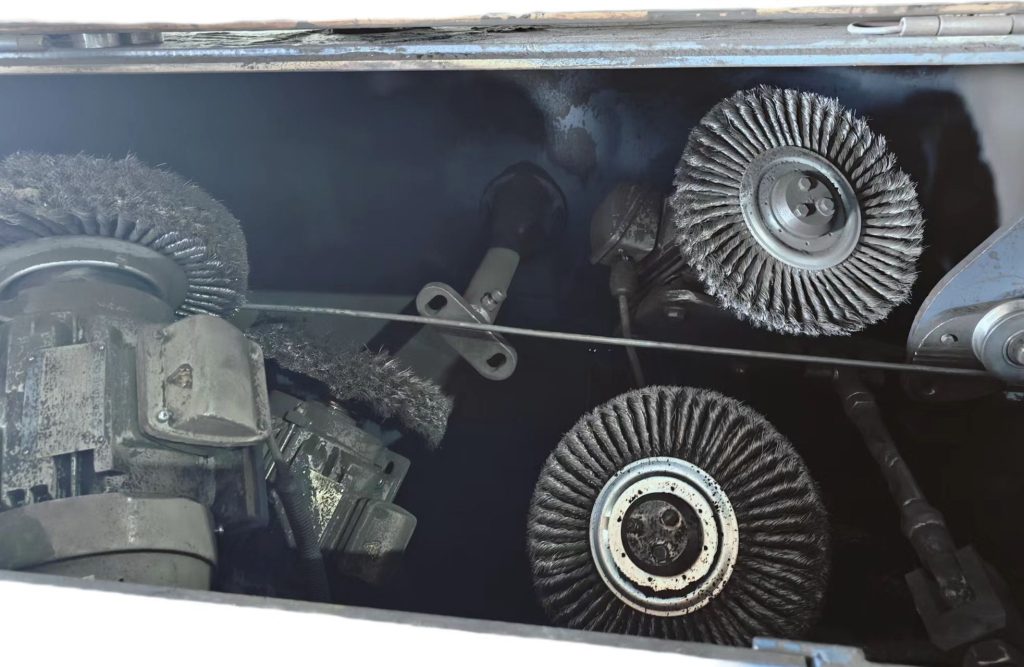

Another essential piece of Steel Brush Descaler for Wire Drawing Process is the lubrication system. As the wire is pulled through the dies, friction can build up, causing heat and wear on both the wire and the dies. A lubrication system is used to reduce friction and heat, allowing the wire to move more smoothly through the dies and reducing wear on the equipment. This not only improves the efficiency of the drawing process but also helps to extend the life of the dies and other components.

In addition to wire straighteners and lubrication systems, there are several other types of auxiliary equipment that are commonly used in wire drawing. These include spoolers, which are used to wind the drawn wire onto spools for storage and transportation, and tension control systems, which help to maintain a consistent tension on the wire as it is drawn through the dies. These auxiliary equipment pieces work together to ensure that the wire drawing process runs smoothly and efficiently, producing high-quality wire products.

The importance of auxiliary equipment in the wire drawing process cannot be overstated. Without these essential pieces of equipment, the quality of the wire products produced would be compromised, and the efficiency of the process would be greatly reduced. By investing in high-quality auxiliary equipment and ensuring that it is properly maintained and operated, manufacturers can improve the quality of their wire products, reduce downtime and maintenance costs, and increase overall productivity.

In conclusion, auxiliary equipment plays a crucial role in the wire drawing process, helping to ensure the efficiency and quality of the final product. Wire straighteners, lubrication systems, spoolers, and tension control systems are just a few examples of the essential auxiliary equipment used in wire drawing. By investing in high-quality auxiliary equipment and ensuring that it is properly maintained and operated, manufacturers can improve the quality of their wire products, reduce downtime and maintenance costs, and increase overall productivity.