Table of Contents

IiNzuzo zokuSebenzisa uMtshini wokuThatha i-Spool kwiMveliso yeLaphu

Indlela yokuGcina ngokuchanekileyo kunye nokuXoxa iSpool yokuThatha umatshini

Ekuqukumbeleni, umatshini wokuthatha i-spool yinxalenye ebalulekileyo yesixhobo esifuna ukugcinwa okufanelekileyo kunye nokusombulula iingxaki ukuqinisekisa ukusebenza kwayo ngokupheleleyo. Ngokuhlola rhoqo kunye nokucoca umatshini, kunye nokujongana nayo nayiphi na imiba ngokukhawuleza, unokwandisa ixesha lokuphila kunye nokwandisa ukusebenza kwayo. Khumbula ukulandela izikhokelo zomenzi zolungiso kunye nokusombulula ingxaki ukugcina i-spool yakho ithatha umatshini ukwimeko ephezulu.

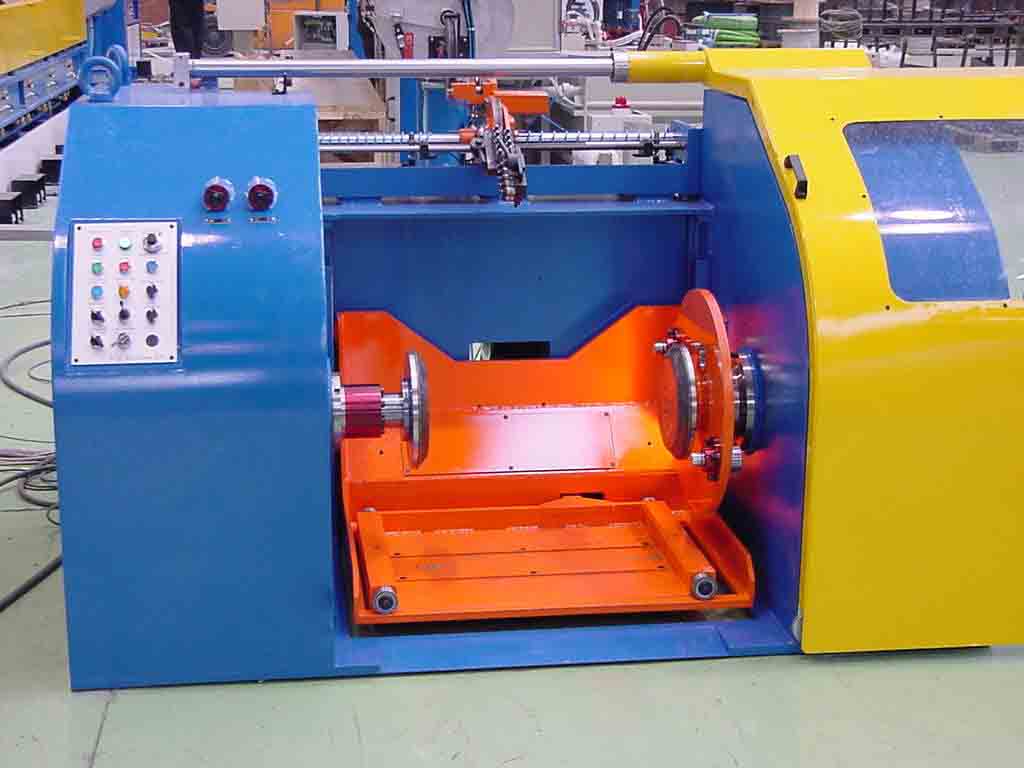

Spool take up machines are essential equipment in various industries, including textile, wire and cable, and packaging. These machines are used to wind materials onto spools or reels, ensuring efficient production processes. Proper maintenance and troubleshooting of a spool take up machine are crucial to ensure its optimal performance and longevity.

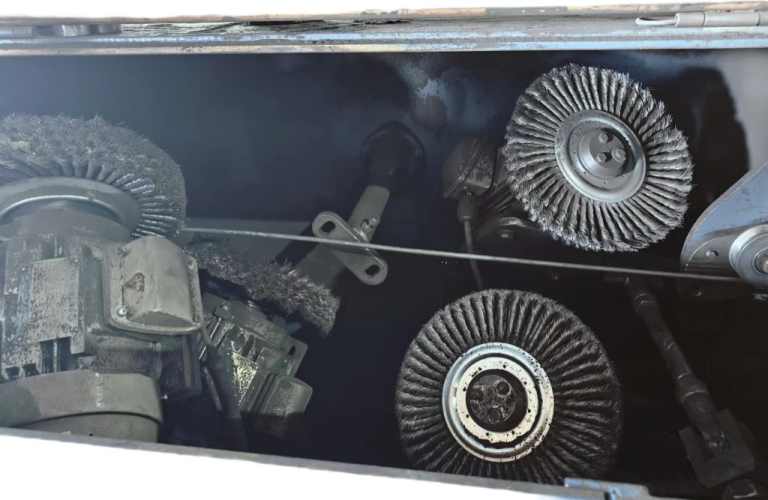

Regular maintenance of a spool take up machine is essential to prevent breakdowns and ensure smooth operation. One of the key maintenance tasks is to regularly inspect the machine for any signs of wear and tear. Check for loose or damaged parts, such as belts, bearings, and gears, and replace them as needed. Lubricate moving parts to reduce friction and prevent premature wear.

Another important maintenance task is to clean the machine regularly to remove dust, dirt, and debris that can accumulate and affect its performance. Use a soft brush or cloth to clean the machine thoroughly, paying special attention to the spool winding mechanism and the tension control system. Avoid using harsh chemicals or abrasive materials that can damage the machine.

In addition to regular maintenance, it is important to troubleshoot any issues that may arise with a spool take up machine promptly. One common issue is uneven winding, which can result in spools that are not properly wound and can cause production delays. To troubleshoot this issue, check the tension control system and adjust it as needed to ensure even winding.

Another common issue is spool slippage, where the spool does not rotate properly on the winding shaft. This can be caused by a loose or worn winding shaft, or a malfunctioning clutch mechanism. Inspect the winding shaft and clutch mechanism for any signs of damage and replace them if necessary to resolve the issue.

If the machine is making unusual noises or vibrations during operation, it may indicate a problem with the bearings or gears. Inspect these components for any signs of wear or damage and replace them if needed. It is also important to check the alignment of the machine to ensure that all components are properly aligned and functioning correctly.

Properly maintaining and troubleshooting a spool take up machine requires attention to detail and regular monitoring of its performance. By following these maintenance tips and addressing any issues promptly, you can ensure that your machine operates efficiently and reliably, reducing downtime and increasing productivity.

In conclusion, a spool take up machine is a valuable piece of equipment that requires proper maintenance and troubleshooting to ensure its optimal performance. By regularly inspecting and cleaning the machine, as well as addressing any issues promptly, you can extend its lifespan and maximize its efficiency. Remember to follow the manufacturer’s guidelines for maintenance and troubleshooting to keep your spool take up machine in top condition.