Table of Contents

Step-by-Step na Gabay sa Paano Wastong Gumamit ng Steel Brush Descaler

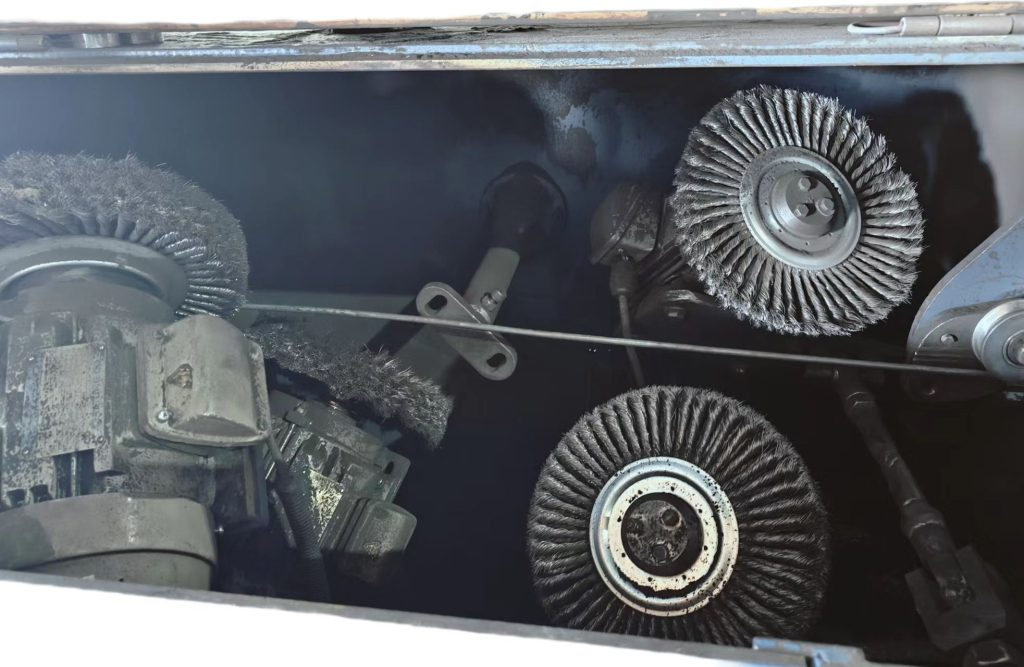

Steel brush descaler para sa proseso ng pagguhit ng wire ay mahahalagang tool para sa pag-alis ng kalawang, pintura, at iba pang mga debris mula sa mga metal na ibabaw. Propesyonal mang welder ka man o mahilig sa DIY, ang pag-alam kung paano wastong gumamit ng steel brush descaler ay napakahalaga para sa pagkamit ng pinakamahusay na mga resulta. Sa step-by-step na gabay na ito, gagabayan ka namin sa proseso ng paggamit ng steel brush descaler nang epektibo.

Una sa lahat, mahalagang tiyakin na mayroon kang tamang gamit sa kaligtasan bago gamitin isang steel brush descaler. Kabilang dito ang pagsusuot ng guwantes, salaming pangkaligtasan, at isang dust mask upang protektahan ang iyong sarili mula sa lumilipad na mga labi at mapaminsalang usok. Kapag naisuot mo na ang iyong kagamitang pangkaligtasan, maaari mong simulan ang proseso ng paggamit ng steel brush descaler.

Ang unang hakbang ay ihanda ang ibabaw na iyong aalisin ng pagkakascale. Maaaring kabilang dito ang pag-alis ng anumang maluwag na mga labi o kalawang gamit ang Wire Brush Descaler Machine o papel de liha. Kapag malinis at tuyo na ang ibabaw, maaari mong simulan ang paggamit ng steel brush descaler.

Kapag gumagamit ng steel brush descaler, mahalagang magsimula sa mababang bilis at unti-unting taasan ang bilis kung kinakailangan. Makakatulong ito na maiwasan ang pinsala sa ibabaw ng metal at matiyak ang mas pantay na pagtatapos. Mahalaga rin na panatilihing pabalik-balik ang paggalaw ng descaler upang maiwasan ang paggawa ng mga uka o gasgas sa metal.

Habang nagtatrabaho ka, tiyaking pana-panahong suriin ang pag-usad ng proseso ng descaling. Makakatulong ito sa iyo na matukoy kung ang ibabaw ay malinis at walang kalawang, pintura, o iba pang mga labi. Kung kinakailangan, maaari ka ring mag-apply ng rust inhibitor o primer upang maprotektahan ang ibabaw ng metal mula sa hinaharap na kaagnasan.

Kapag natapos mo na ang pag-descale sa ibabaw, mahalagang linisin nang lubusan ang steel brush descaler. Makakatulong ito na maiwasan ang pagtatayo ng mga debris at matiyak na ang descaler ay nananatiling nasa mabuting kondisyon sa pagtatrabaho. Maaari kang gumamit ng wire brush o compressed air upang alisin ang anumang mga debris mula sa mga bristles ng descaler.

Sa wakas, mahalagang itabi nang maayos ang steel brush descaler upang maiwasan ang pinsala at matiyak ang mahabang buhay nito. Maaaring kabilang dito ang pag-iimbak ng descaler sa isang tuyo, malamig na lugar na malayo sa moisture at matinding temperatura. Mahalaga rin na regular na suriin ang descaler para sa anumang senyales ng pagkasira o pagkasira at palitan ang anumang pagod o nasirang bahagi kung kinakailangan.

Sa konklusyon, ang paggamit ng steel brush descaler ay isang simple at epektibong paraan upang maalis ang kalawang, pintura, at iba pa. mga labi mula sa mga ibabaw ng metal. Sa pamamagitan ng pagsunod sa mga hakbang na nakabalangkas sa gabay na ito, maaari mong matiyak na ginagamit mo nang maayos ang descaler at nakakamit ang pinakamahusay na mga resulta. Tandaan na laging unahin ang kaligtasan, ihanda nang maayos ang ibabaw, at linisin at iimbak ang descaler nang tama upang mapanatili ang pagiging epektibo nito. Sa pag-iisip ng mga tip na ito, maaari mong kumpiyansa na matugunan ang anumang descaling na proyekto nang madali.

Mga Benepisyo ng Paggamit ng Steel Brush Descaler para sa Pag-alis ng kalawang

Ang kalawang ay isang pangkaraniwang problema na sumasalot sa maraming ibabaw ng metal, na nagiging sanhi ng pagkasira ng mga ito sa paglipas ng panahon. Kung ito man ay sa isang kotse, isang piraso ng makinarya, o isang appliance sa bahay, ang kalawang ay maaaring hindi magandang tingnan at nakakapinsala. Sa kabutihang palad, may mga tool na magagamit upang makatulong na labanan ang isyung ito, isa sa mga ito ay isang Mechanical brush descaler.

Ang steel brush descaler ay isang tool na partikular na idinisenyo upang alisin ang kalawang sa mga metal na ibabaw. Binubuo ito ng isang hawakan na nakakabit sa isang brush na gawa sa bakal na bristles. Ang mga bristles ay malakas at matibay, na ginagawang epektibo ang mga ito sa pagkayod ng kalawang at iba pang mga labi mula sa mga metal na ibabaw. Ang paggamit ng steel brush descaler ay makakatulong sa pagpapanumbalik ng hitsura ng mga metal na ibabaw at maiwasan ang karagdagang kaagnasan.

Isa sa mga pangunahing benepisyo ng paggamit ng steel brush descaler ay ang pagiging epektibo nito sa pag-alis ng kalawang. Ang mga bakal na bristles ay sapat na abrasive upang kuskusin kahit ang pinakamatinding mantsa ng kalawang, na nag-iiwan ng malinis at makinis na ibabaw. Makakatulong ito na pahabain ang buhay ng mga metal na bagay at maiwasan ang mga ito na lumala pa.

Bukod sa pag-alis ng kalawang, makakatulong din ang steel brush descaler sa paghahanda ng mga metal surface para sa pagpipinta o coating. Sa pamamagitan ng pag-alis ng kalawang at iba pang mga labi, ang ibabaw ay nagiging mas makinis at mas madaling tanggapin sa pintura o patong, na tinitiyak ang mas mahusay na pagdirikit at isang mas matagal na pagtatapos. Maaari itong maging partikular na kapaki-pakinabang para sa mga automotive o pang-industriya na aplikasyon kung saan ang isang makinis at matibay na ibabaw ay mahalaga.

Ang isa pang benepisyo ng paggamit ng steel brush descaler ay ang versatility nito. Maaari itong magamit sa isang malawak na hanay ng mga ibabaw ng metal, kabilang ang bakal, bakal, at aluminyo. Gumagawa ka man ng isang maliit na proyekto sa bahay o isang malaking pang-industriya na trabaho, ang isang steel brush descaler ay makakatulong sa iyo na harapin ang pag-alis ng kalawang nang madali.

Ang paggamit ng steel brush descaler ay isa ring cost-effective na solusyon para sa pag-alis ng kalawang. Sa halip na palitan ang mga metal na bagay na nasira ng kalawang, maaari mo lamang gamitin ang isang steel brush descaler upang linisin at ibalik ang mga ito. Makakatipid ito sa iyo ng oras at pera sa katagalan, dahil hindi mo na kailangang patuloy na palitan ang mga kinakalawang na item.

Higit pa rito, ang paggamit ng steel brush descaler ay isang ligtas at environment friendly na paraan upang alisin ang kalawang. Hindi tulad ng mga malupit na kemikal o acid, ang isang steel brush descaler ay hindi gumagawa ng mga mapaminsalang usok o residues na maaaring makasama sa iyong kalusugan o sa kapaligiran. Ito ay isang simple at epektibong tool na maaaring magamit nang may kaunting panganib.

Sa konklusyon, ang steel brush descaler ay isang mahalagang tool para sa pag-alis ng kalawang mula sa mga metal na ibabaw. Ang pagiging epektibo, versatility, cost-effectiveness, at kaligtasan nito ay ginagawa itong mainam na pagpipilian para sa sinumang naghahanap upang ibalik ang mga bagay na metal sa kanilang dating kaluwalhatian. Ikaw man ay isang DIY enthusiast o isang propesyonal na mangangalakal, ang isang steel brush descaler ay makakatulong sa iyo na harapin ang pag-alis ng kalawang nang madali. Kaya sa susunod na maharap ka sa kalawang na ibabaw ng metal, isaalang-alang ang paggamit ng steel brush descaler upang magawa ang trabaho nang mahusay at epektibo.