Table of Contents

Tips for Maintaining and Optimizing straight line wire drawing machine For Low Carbon Steel Wire Production

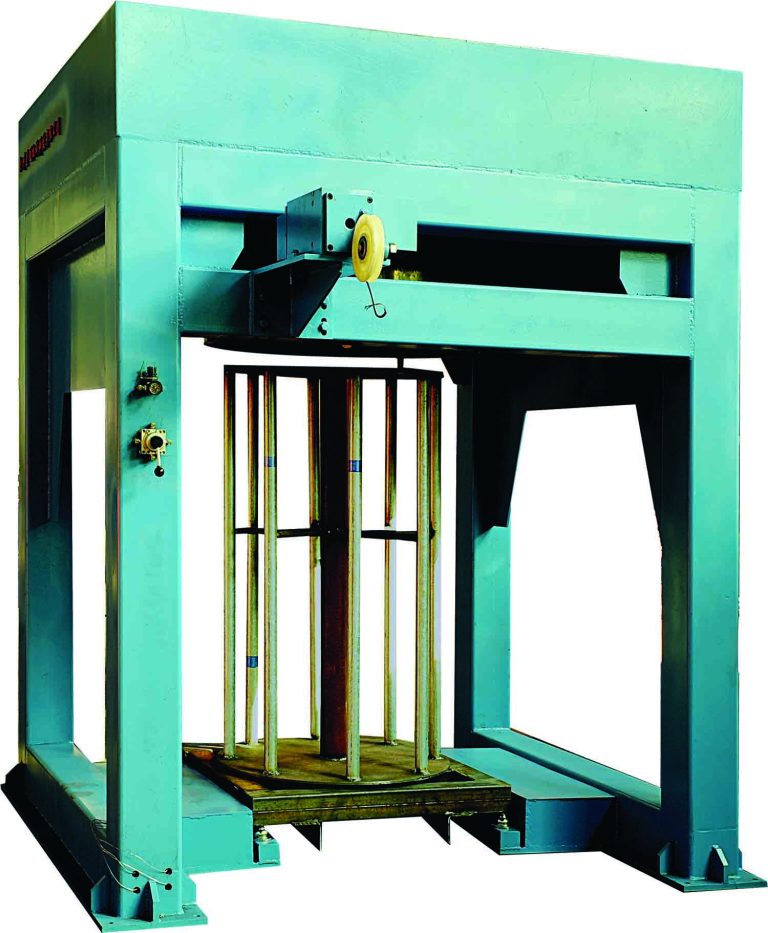

Straight line wire drawing machines are essential equipment in the production of low carbon steel wire. These machines are designed to pull wire through a series of dies to reduce its diameter and improve its quality. To ensure the efficient operation of straight line wire drawing machines, proper maintenance and optimization are crucial. In this article, we will discuss some tips for maintaining and optimizing straight line wire drawing machine for low carbon steel wire production.

Regular cleaning and lubrication are key to keeping straight line wire drawing machines in optimal condition. Dirt, dust, and debris can accumulate on the machine’s components, leading to increased friction and wear. Regularly cleaning the machine with a soft brush and compressed air can help prevent these issues. Additionally, lubricating the machine’s moving parts with a high-quality lubricant will reduce friction and prolong the life of the machine.

Inspecting the machine’s dies and rollers is another important maintenance task. Over time, these components can wear out or become damaged, leading to poor wire quality and reduced production efficiency. Regularly inspecting the dies and rollers for signs of wear or damage and replacing them as needed will help ensure the machine operates smoothly and produces high-quality wire.

Calibrating the machine’s speed and tension settings is essential for optimizing its performance. Properly calibrated speed and tension settings will ensure that the wire is drawn through the dies at the correct rate and with the right amount of tension. This will help prevent wire breakage and ensure consistent wire quality. Regularly checking and adjusting the machine’s speed and tension settings will help optimize its performance and improve production efficiency.

Monitoring the machine’s power consumption is another important aspect of maintaining and optimizing straight line wire drawing machines. High power consumption can indicate inefficiencies in the machine’s operation, such as excessive friction or improper calibration. By monitoring the machine’s power consumption and identifying any abnormalities, operators can take corrective action to improve the machine’s efficiency and reduce energy costs.

Regularly inspecting the machine’s electrical components is also crucial for maintaining its performance. Faulty electrical components can cause the machine to malfunction or operate inefficiently. Regularly inspecting the machine’s electrical components for signs of wear or damage and replacing them as needed will help ensure the machine operates safely and efficiently.

In conclusion, maintaining and optimizing straight line wire drawing machines for low carbon steel wire production is essential for ensuring efficient operation and high-quality wire output. By following the tips outlined in this article, operators can keep their machines in optimal condition and maximize production efficiency. Regular cleaning and lubrication, inspecting and replacing worn components, calibrating speed and tension settings, monitoring power consumption, and inspecting electrical components are all important aspects of maintaining and optimizing straight line wire drawing machines. By taking these steps, operators can ensure that their machines operate smoothly and produce high-quality wire for various applications.

Benefits of Using Straight Line Wire Drawing Machines for Low Carbon Steel Wire

Wire drawing is a process used to reduce the diameter of a wire by pulling it through a series of dies. This process is commonly used in the manufacturing of various types of wires, including low carbon steel wire. Straight line wire drawing machines are a popular choice for this application due to their efficiency and effectiveness in producing high-quality wire products.

One of the key benefits of using Dry Type Wire Drawing Machine for low carbon steel wire is their ability to produce consistent and uniform wire. These machines are designed to pull the wire through a series of dies in a straight line, ensuring that the diameter of the wire is reduced evenly across its entire length. This results in a high-quality wire product that meets the required specifications for strength and durability.

In addition to producing uniform wire, straight line wire drawing machines also offer a high level of precision in the wire drawing process. These machines are equipped with advanced controls that allow operators to adjust the speed and tension of the wire as it passes through the dies. This level of control ensures that the wire is drawn to the exact diameter required, resulting in a precise and accurate finished product.

Another benefit of using straight line wire drawing machines for low carbon steel wire is their efficiency in the production process. These machines are capable of drawing wire at high speeds, allowing manufacturers to produce large quantities of wire in a short amount of time. This can help to reduce production costs and increase overall productivity, making straight line wire drawing machines a cost-effective solution for wire manufacturers.

Furthermore, straight line wire drawing machines are designed to be durable and reliable, ensuring consistent performance over time. These machines are built to withstand the rigors of continuous operation, making them a long-lasting investment for wire manufacturers. With proper maintenance and care, straight line wire drawing machines can provide years of reliable service, helping manufacturers to meet their production goals and deliver high-quality wire products to their customers.

In conclusion, straight line wire drawing machines offer a range of benefits for manufacturers of low carbon steel wire. From producing uniform and precise wire products to increasing efficiency and productivity in the production process, these machines are a valuable asset for wire manufacturers looking to improve their operations. With their durability and reliability, straight line wire drawing machines are a smart investment for any manufacturer looking to enhance their wire drawing capabilities and deliver high-quality products to their customers.