Low Carbon Steel Wire straight line wire drawing machine

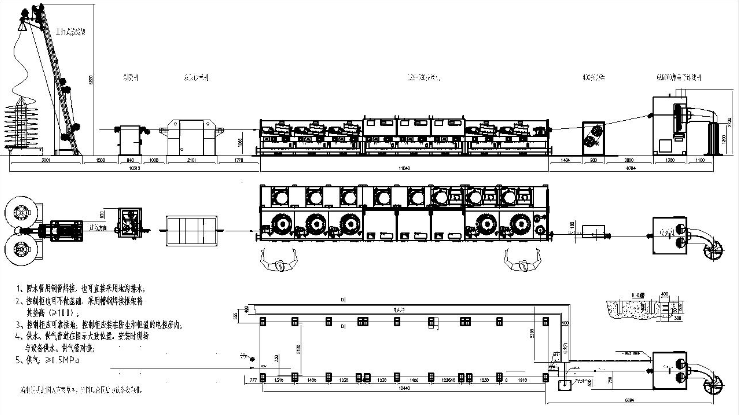

The complete wire drawing line composed of Wire rod payoff,Reversed Bending Descaler,Sand Belt Grinding Descaler,Straight line wire drawing machine,Wire Spooling Machine or Dead Block Coiler, or Vetical drop colier.

Wire rod payoff is for the wire rod decoiling

Reversed bending descaler:

The wire rod is bent through one or more sets of guide pulleys, and the outer edge of the wire rod produces a large amount of extension. Because the ductility of oxides is lower than that of carbide. Therefore, the oxide scale peels off the surface of the wire rod. Through the tensile test, it can be determined how much the various wire rods are stretched and the oxide scale will peel off. This can help determine an appropriate bending deformation parameter.

Sand Belt Grinding Descaler,

Descaling sandpaper machine

Material to treat: low carbon steel wire rod high carbon steel wire rod

Wire Dia. range:Φ5.5mm-Φ8.0mm

Max. speed:150m/min

Tensile strength:200mpa—2500mpa

Descaling device:4 descaling rollers for two directions

Straight line Wire Drawing Machine,

| Capstan Dia.-mm | 300 | 350 | 400 | 450 | 500 | 560 | 600 | 700 | 800 | 900 | 1000 | 1200 |

| Material Strength | ≤1250Mpa | |||||||||||

| Drawing No. | 2-11 | 2-11 | 2-11 | 2-12 | 2-12 | 2-12 | 2-12 | 2-9 | 2-9 | 2-9 | 2-9 | 2-9 |

| Max.Inlet.Dia.-mm | 2.8 | 3.5 | 4.2 | 5.0 | 5.5 | 6.5 | 8 | 10 | 12.7 | 13 | 13 | 14 |

| Min.Outlet.Dia..-mm | 0.5 | 0.6 | 0.75 | 1.0 | 1.2 | 1.4 | 1.6 | 2.2 | 2.6 | 3.0 | 3.5 | 4.0 |

| Max.Speed-m/s | 25 | 20 | 20 | 16 | 15 | 15 | 12 | 12 | 8 | 7 | 6 | 6 |

| Drawing Power-KW | 7.5-11 | 11-18.5 | 11-22 | 15-30 | 18.5-30 | 22-45 | 30-45 | 37-55 | 45-75 | 90-132 | 90-132 | 110-160 |

| Transmission | one-class belt transmission, Hardened gear reducer transmission | |||||||||||

| Electrical Control | PROFIBUS system with touch screen input and PLC control | |||||||||||

| Take-up By | Spooler, Dead Block Coiler or Vertical Drop Coiler | |||||||||||

| Features | Target weight presetting, Multiple choices for capstan option, Smart monitoring | |||||||||||

| Material to Draw | For low, mild, high carbon steel materials | |||||||||||

| Remarks | Details up to final product and production technology | |||||||||||

Dead block Coiler

Quality – even at the end of the drawing process. Our static coilers achieve high processing speeds. Lifeblock coilers function without torsion and enable high fill weights – when coiling thick wires, for instance.

Static Coiler With Horizontal Capstan, for high speed Mainly for low carbon steel wire

Integration of pattern laying system possible.

Inlet dia. lc (mm): 1.5 – 5.0

Inlet dia. hc (mm): 1.5 – 3.5

Capstan dia. (mm): 600

Drive power (kW): 37

Inlet speed (m/s): max. 30

The machine Elecrical control system

PROFIBUS or PROFINET system with touch screen input and PLC control for the complete line.

There are some opionals for the final user,

- 1, the aircon for the electrical cabinet

- 2, The electricity meters,

- 3,The main machine power on or off control switch.