Table of Contents

How to Optimize Efficiency in Multi-line Copper-coating Production Line for CO2 Welding Wire

In the manufacturing industry, efficiency is key to success. This is especially true in the production of CO2 welding wire, where every step in the process must be optimized to ensure a high-quality end product. One crucial aspect of this process is the copper-coating production line, which plays a vital role in enhancing the conductivity and corrosion resistance of the welding wire.

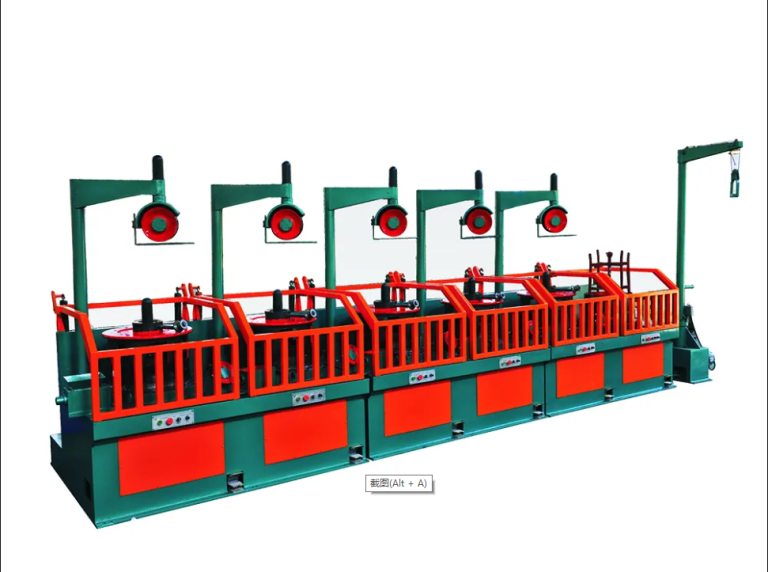

To optimize efficiency in a High Speed Copper-Coating Line For CO2 Welding Wire, several factors must be taken into consideration. One of the most important aspects is the design of the production line itself. The layout of the line should be carefully planned to minimize the distance between each stage of the process, reducing the time it takes for the wire to move from one station to the next. This can help to increase the overall throughput of the line and reduce the risk of bottlenecks occurring.

Another key factor in optimizing efficiency is the use of automation and robotics in the production process. By automating certain tasks, such as the application of the copper coating or the inspection of the finished wire, manufacturers can significantly reduce the amount of time and labor required to produce each batch of welding wire. This not only helps to increase efficiency but also improves the consistency and quality of the end product.

In addition to automation, the use of advanced monitoring and control systems can also help to optimize efficiency in a multi-line copper-coating production line. By closely monitoring key parameters such as wire diameter, coating thickness, and line speed, manufacturers can quickly identify any issues that may arise during the production process and take corrective action before they escalate. This can help to minimize downtime and reduce the risk of producing defective welding wire.

Furthermore, the use of high-quality materials and equipment is essential for optimizing efficiency in a multi-line copper-coating production line. By investing in top-of-the-line machinery and tools, manufacturers can ensure that their production line operates at peak performance and produces welding wire of the highest quality. This can help to reduce waste, improve productivity, and ultimately increase profitability.

Finally, regular maintenance and calibration of the production line are crucial for optimizing efficiency. By keeping equipment in good working order and ensuring that all components are properly calibrated, manufacturers can prevent breakdowns and ensure that the line operates smoothly and efficiently. This can help to minimize downtime and maximize the overall output of the production line.

In conclusion, optimizing efficiency in a multi-line copper-coating production line for CO2 welding wire requires careful planning, the use of automation and advanced monitoring systems, the use of high-quality materials and equipment, and regular maintenance and calibration. By focusing on these key areas, manufacturers can improve the productivity and profitability of their production line while also ensuring that they produce welding wire of the highest quality.

Benefits of Using Multi-line Copper-coating Production Line for CO2 Welding Wire

CO2 welding wire is a crucial component in the welding industry, used in various applications such as automotive, construction, and manufacturing. To ensure the quality and performance of CO2 welding wire, it is essential to have a reliable and efficient production line. One of the most advanced and effective production lines for CO2 welding wire is the multi-line copper-coating production line.

The High Speed Copper Coating Production Line For CO2 Welding Wire Line is designed to increase productivity and efficiency in the manufacturing process of CO2 welding wire. By incorporating multiple lines within the production system, manufacturers can produce a higher volume of welding wire in a shorter amount of time. This not only helps to meet the demands of the market but also reduces production costs and increases profitability.

One of the key benefits of using a multi-line copper-coating production line for CO2 welding wire is the improved quality of the final product. The copper coating plays a crucial role in enhancing the performance and durability of the welding wire. By using a multi-line production system, manufacturers can ensure a consistent and uniform coating on each wire, resulting in a higher quality product that meets industry standards.

In addition to improving product quality, the multi-line copper-coating production line also offers increased flexibility and versatility in the manufacturing process. Manufacturers can easily adjust the production speed and output of each line to meet changing market demands. This flexibility allows for quick response to customer orders and ensures timely delivery of welding wire products.

Furthermore, the multi-line copper-coating production line is equipped with advanced technology and automation systems that help to streamline the manufacturing process. Automated controls and monitoring systems ensure precise coating thickness and uniformity, reducing the risk of defects and inconsistencies in the final product. This not only improves product quality but also reduces waste and rework, leading to cost savings for manufacturers.

Another significant benefit of using a multi-line copper-coating production line for CO2 welding wire is the increased production capacity. With multiple lines running simultaneously, manufacturers can significantly increase their output and meet the growing demand for welding wire in the market. This scalability allows for business growth and expansion, as manufacturers can easily ramp up production to meet the needs of their customers.

Overall, the multi-line copper-coating production line offers numerous benefits for manufacturers in the welding industry. From improved product quality and flexibility to increased production capacity and cost savings, this advanced production system is a valuable investment for any welding wire manufacturer. By incorporating a multi-line copper-coating production line into their manufacturing process, companies can enhance their competitiveness in the market and achieve greater success in the industry.