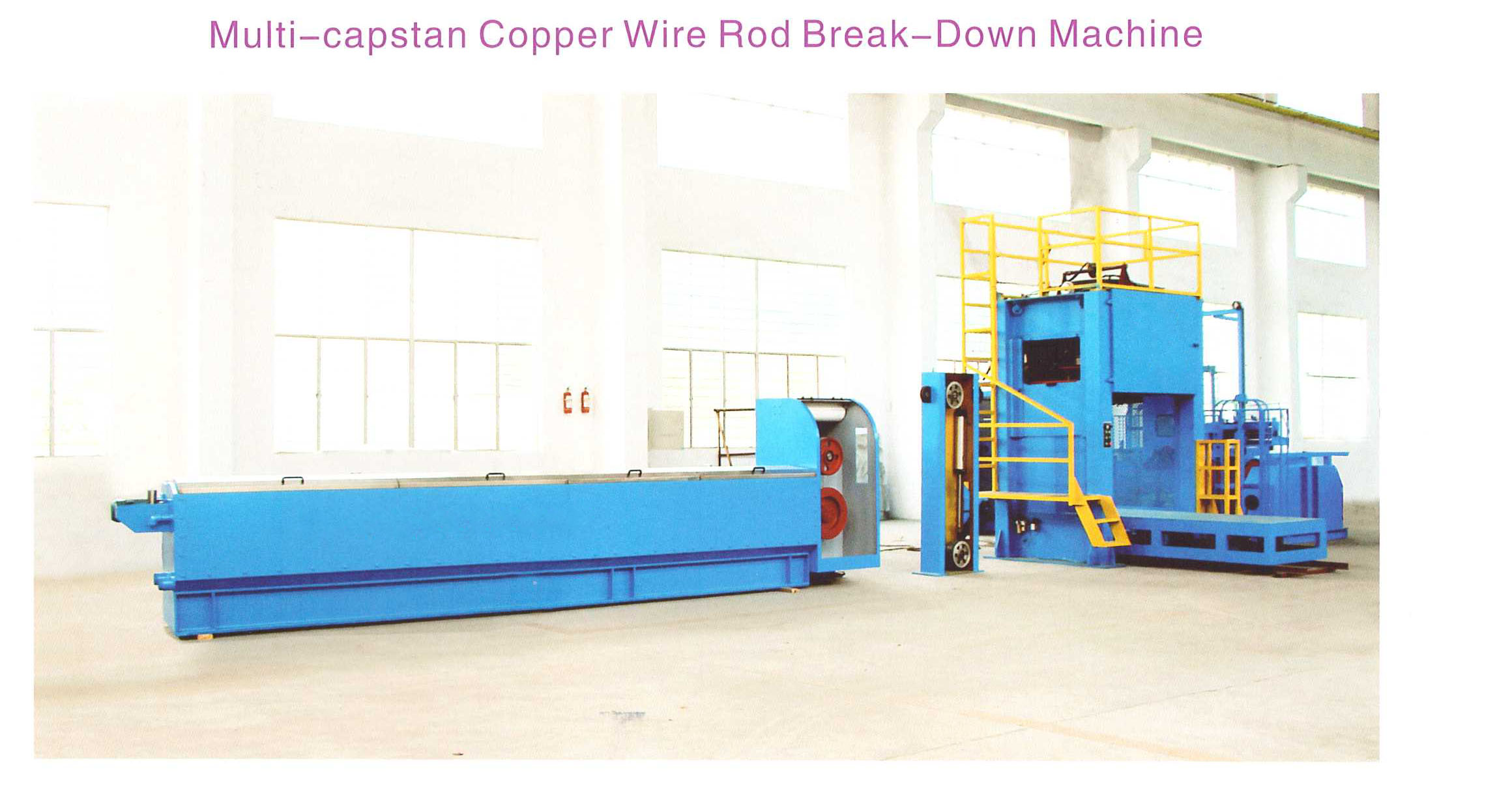

wet wire drawing machine For Copper Wire,Wet Wire Drawing Machine

It is used to drawing and annealing copper rod. In addition, it is applied to making electric wire. Our company will provide a series of production equipment to meet our customers’ need, concluding drawing machine, rigid frame stranding machine and extruder.

•Wet type drawing machines are best suited for breaking down copper and aluminium wires, and drawing iron and steel wires.

•Worm gear or spiral bevel gear capstan drive system reduces transmission noise and vibration.

•Take your choice of spooler, non-stop coiler, or bending coiler take-up systems.

| Machine type | LHT400/13 | LHT400/11 | LHT400/9 | LHT400/8 | ||

| Power control | Double inverter control | |||||

| Inlet Dia.(mm) | 8 | |||||

| Outlet Dia.(mm) | 1.2~3.2 | 1.7~3.2 | 2.3~3.2 | 2.6~3.2 | ||

| Drawing Drum Dia.(mm) | 400 | |||||

| Fix speed capstan Dia.(mm) | 400 | |||||

| Max.Die No. | 13 | 11 | 9 | 8 | ||

| Drawing Speed(Max.)(m/s) | 15 | 12 | 12 | 11 | ||

| Main Motor (KW) | 160(AC/DC) | 132(AC/DC) | ||||

| Drum arrangement | Horizontal type | |||||

| Drawing drum | Coated by tungsten | |||||

| Drum lubrication type | Immersed type | |||||

| Gear,bearing lubrication | By special pump,spray type | |||||

| Online Continuous Annealer | ||||||

| Machine structure | Horizontal type | |||||

| Annealing wheel dia,(mm) | 350 | |||||

| Max annealing voltage(V) | 65V(DC) | 60V(DC) | ||||

| Max annealing current(A) | 4500 | 4000 | ||||

| Take-up type(optional) | Double Take-up/Single Take-up/Colier | |||||

| Optional equipment | Horizontal continuous annealer online | |||||

| Optional function | Fast change die | |||||

Packing&Shipping

According to customer requirements