Table of Contents

Step-by-Step Guide on How to Properly Use a Steel Brush Descaler for Effective Scale Removal

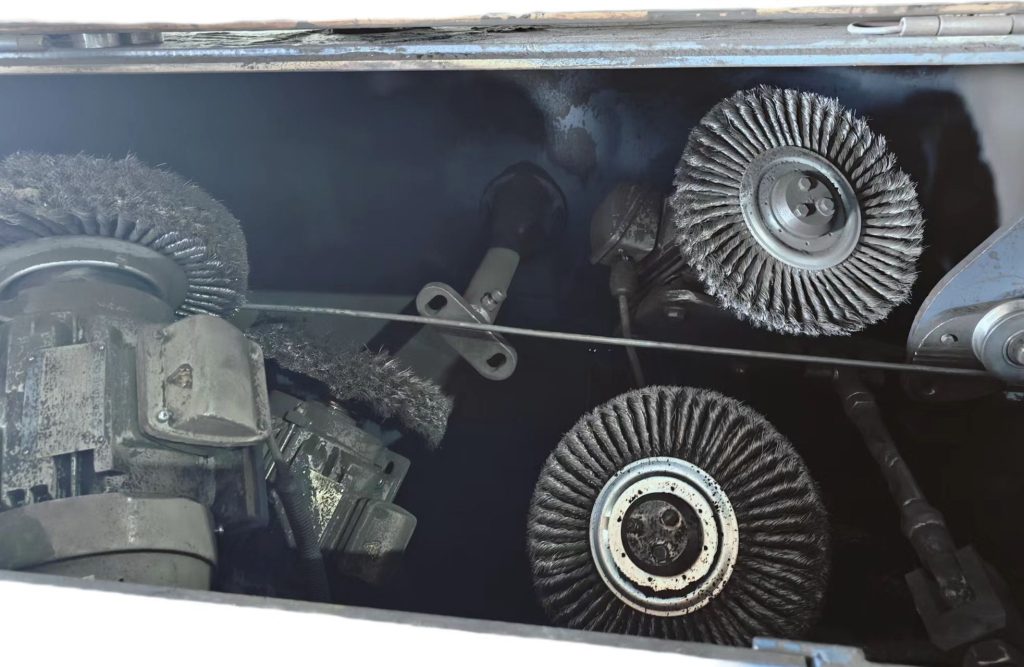

A steel Wire Brush Descaler Machine is a powerful tool used for removing scale and rust from metal surfaces. It is commonly used in industrial settings, such as manufacturing plants and construction sites, to clean and prepare metal surfaces for painting or welding. Using a steel brush descaler properly is essential to ensure effective scale removal and to prevent damage to the metal surface.

To begin using a steel brush descaler, it is important to first inspect the tool for any damage or wear. Check the bristles of the brush to make sure they are in good condition and securely attached to the handle. If any bristles are loose or damaged, replace the brush before using it to avoid scratching or damaging the metal surface.

Next, prepare the metal surface for descaling by removing any loose debris or dirt. Use a wire brush or a rag to clean the surface and ensure that it is free of any contaminants that could interfere with the descaling process. It is important to work in a well-ventilated area and wear appropriate safety gear, such as gloves and goggles, to protect yourself from flying debris and fumes.

Once the metal surface is clean and prepared, it is time to begin using the Mechanical brush descaler. Hold the tool firmly in your hand and apply gentle pressure to the metal surface. Move the brush back and forth in a sweeping motion, following the direction of the grain of the metal. Avoid using excessive force, as this can cause damage to the surface and wear out the bristles of the brush more quickly.

As you work, periodically check the progress of the descaling process to ensure that you are effectively removing the scale and rust from the metal surface. If necessary, apply a rust remover or lubricant to stubborn areas to help loosen the scale and make it easier to remove. Be patient and thorough in your work, taking care to cover all areas of the metal surface to achieve a uniform finish.

After you have finished descaling the metal surface, clean the area with a rag or brush to remove any remaining debris or residue. Inspect the surface to ensure that all scale and rust have been removed and that the metal is clean and ready for further treatment or finishing. If necessary, repeat the descaling process in areas where scale or rust remains.

In conclusion, using a steel brush descaler properly is essential for effective scale removal and for maintaining the integrity of the metal surface. By following these steps and taking care to work diligently and patiently, you can achieve a clean and smooth finish on your metal surfaces. Remember to always wear appropriate safety gear and to inspect your tools regularly to ensure that they are in good working condition. With proper care and attention, a steel brush descaler can be a valuable tool for maintaining and preparing metal surfaces in a variety of industrial settings.

How to Choose the Right Steel Brush Descaler for Your Specific Needs

When it comes to removing rust, paint, or other stubborn coatings from metal surfaces, a steel brush descaler can be a valuable tool. However, with so many options available on the market, choosing the right steel brush descaler for your specific needs can be a daunting task. In this article, we will discuss some key factors to consider when selecting a steel brush descaler to ensure that you get the best results for your project.

One of the first things to consider when choosing a Steel Brush Descaler for Wire Drawing Process is the type of surface you will be working on. Different surfaces may require different types of brushes or bristles to effectively remove the desired coatings. For example, if you are working on a delicate surface, such as a car body or a piece of furniture, you may want to choose a steel brush descaler with softer bristles to avoid damaging the surface. On the other hand, if you are working on a tougher surface, such as a metal beam or a concrete floor, you may need a steel brush descaler with more aggressive bristles to effectively remove the coatings.

Another important factor to consider when choosing a steel brush descaler is the size and shape of the brush head. The size and shape of the brush head will determine how effectively the descaler can reach and remove coatings from tight or hard-to-reach areas. For example, if you are working on a surface with intricate details or crevices, you may want to choose a steel brush descaler with a smaller, more compact brush head to ensure that you can effectively remove coatings from all areas of the surface.

In addition to the size and shape of the brush head, you should also consider the material of the bristles when choosing a steel brush descaler. Steel brush descalers are available with a variety of bristle materials, including steel, brass, and nylon. The material of the bristles will determine how effectively the descaler can remove coatings from the surface, as well as how long the bristles will last before needing to be replaced. Steel bristles are typically the most durable and effective for removing tough coatings, while brass or nylon bristles may be better suited for more delicate surfaces.

When choosing a steel brush descaler, it is also important to consider the power source of the tool. Steel brush descalers are available in both electric and pneumatic models, each with its own advantages and disadvantages. Electric steel brush descalers are typically more powerful and easier to use, but they may be limited by the length of the power cord. Pneumatic steel brush descalers, on the other hand, are more portable and can be used in areas without access to electricity, but they may require a separate air compressor to operate.

In conclusion, choosing the right steel brush descaler for your specific needs requires careful consideration of factors such as the type of surface you will be working on, the size and shape of the brush head, the material of the bristles, and the power source of the tool. By taking these factors into account, you can ensure that you select a steel brush descaler that will effectively remove coatings from your surfaces and provide you with the best results for your project.