Table of Contents

നിങ്ങളുടെ മെഷീന് ശരിയായ നെയിൽ ഡൈസ് എങ്ങനെ തിരഞ്ഞെടുക്കാം

മെഷീൻ നിർമ്മിക്കാൻ നെയിൽ ഡൈസ് ഉപയോഗിക്കുന്നതിൻ്റെ പ്രയോജനങ്ങൾ

അവസാനമായി, ഉയർന്ന നിലവാരമുള്ള നഖങ്ങളുടെ നിർമ്മാണത്തിൽ നെയിൽ ഡൈകൾ ഒരു പ്രധാന പങ്ക് വഹിക്കുന്നു, ഇത് നഖ നിർമ്മാണ യന്ത്രങ്ങളുടെ കാര്യക്ഷമതയ്ക്കും ഫലപ്രാപ്തിക്കും സംഭാവന നൽകുന്ന നിരവധി ആനുകൂല്യങ്ങൾ വാഗ്ദാനം ചെയ്യുന്നു. സ്ഥിരതയും ഏകതാനതയും ഉറപ്പാക്കുന്നത് മുതൽ ഉൽപ്പാദന വേഗതയും വൈവിധ്യവും വർദ്ധിപ്പിക്കുന്നത് വരെ, നെയിൽ ഡൈകൾ നഖ നിർമ്മാണത്തിൻ്റെ ഒരു പ്രധാന ഘടകമാണ്. ഗുണനിലവാരമുള്ള നെയിൽ ഡൈകളിൽ നിക്ഷേപിക്കുന്നതിലൂടെ, നിർമ്മാതാക്കൾക്ക് അവരുടെ ഉൽപ്പന്നങ്ങളുടെ ഗുണനിലവാരം മെച്ചപ്പെടുത്താനും അവരുടെ ഉൽപ്പാദന പ്രക്രിയകൾ കാര്യക്ഷമമാക്കാനും മത്സര വിപണിയുടെ ആവശ്യങ്ങൾ നിറവേറ്റാനും കഴിയും.

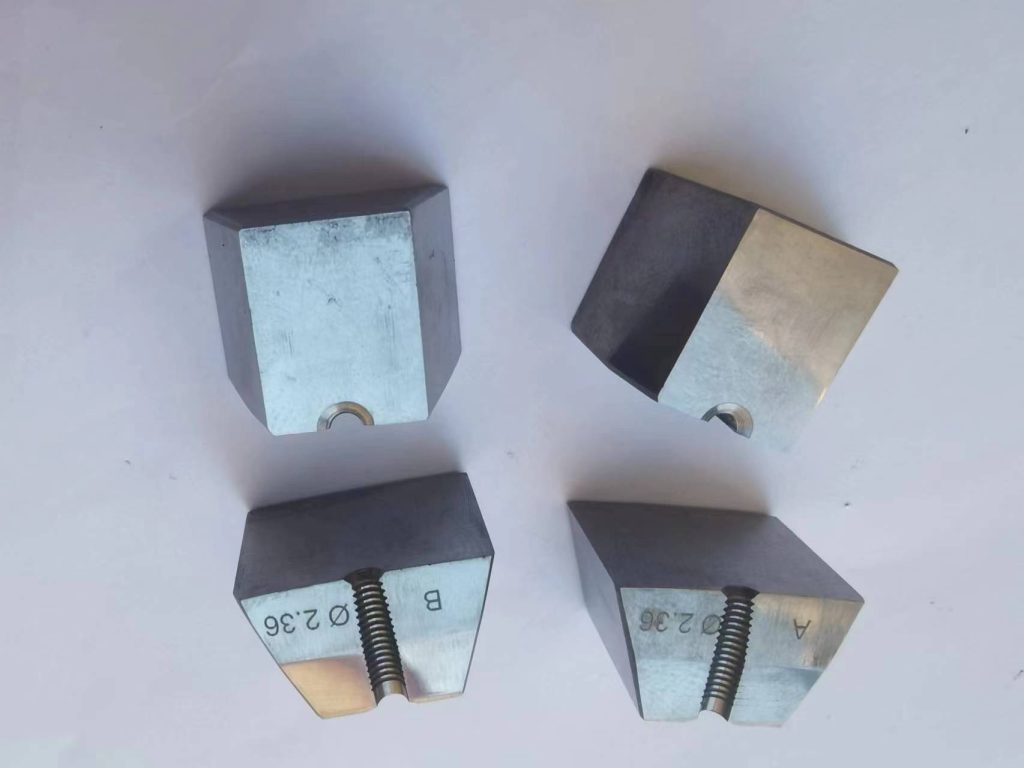

When choosing Nail Dies for your machine, it is essential to consider the type of nails you intend to produce. Different nail dies are designed for producing different types of nails, such as common nails, finishing nails, roofing nails, and spiral nails. It is crucial to select nail dies that are compatible with the type of nails you wish to produce to ensure optimal performance and quality nail production.

In conclusion, choosing the right nail dies for your machine is essential for producing high-quality nails efficiently. When selecting nail dies, it is crucial to consider factors such as material, design, size, and nail type. By choosing nail dies that are compatible with your machine and the type of nails you wish to produce, you can ensure optimal performance and quality nail production.

Benefits of Using Nail Dies for Making Machine

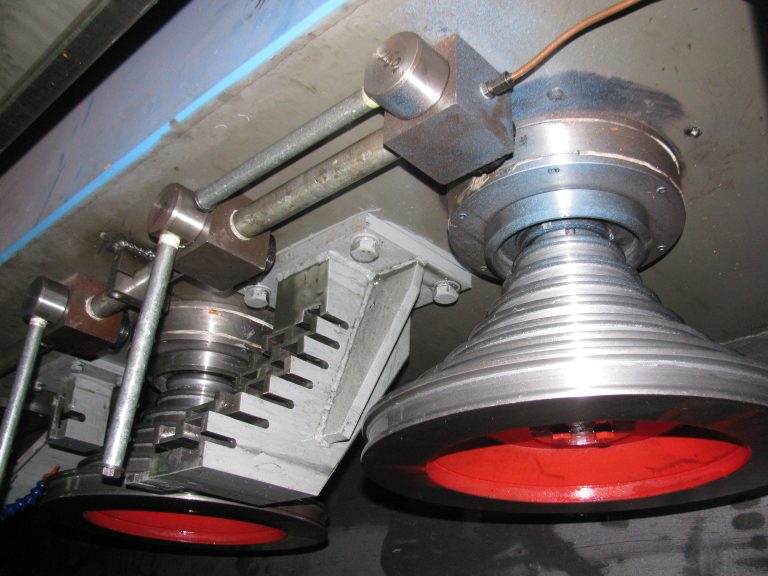

Nail dies are an essential component of Nail Making Machines, playing a crucial role in the production of high-quality nails. These dies are used to shape and cut the wire into the desired nail shape, ensuring precision and consistency in the manufacturing process. There are several benefits to using nail dies for making machines, which contribute to the efficiency and effectiveness of nail production.

One of the primary benefits of using nail dies is the ability to produce nails of consistent size and shape. The dies are designed to create nails with precise dimensions, ensuring uniformity in the final product. This consistency is essential for industries that require nails to meet specific standards and specifications, such as construction and manufacturing.

In addition to uniformity, nail mould also help to increase the production speed of nail making machines. By using dies that are specifically designed for the desired nail shape, manufacturers can streamline the production process and produce nails at a faster rate. This increased efficiency not only saves time but also reduces production costs, making nail manufacturing more cost-effective.

Furthermore, nail dies are durable and long-lasting, providing a reliable solution for nail production. These dies are made from high-quality materials that can withstand the wear and tear of continuous use, ensuring consistent performance over an extended period. This durability reduces the need for frequent replacements and maintenance, saving manufacturers time and money in the long run.

Another benefit of using nail dies for making machines is the versatility they offer in nail production. These dies can be customized to create a wide range of nail shapes and sizes, allowing manufacturers to meet the diverse needs of their customers. Whether producing common nails, finishing nails, or specialty nails, nail dies provide the flexibility to adapt to changing market demands.

Additionally, nail dies contribute to the overall quality of the nails produced. By using dies that are precision-engineered, manufacturers can ensure that each nail meets the highest standards of quality and performance. This attention to detail results in nails that are strong, durable, and reliable, meeting the expectations of customers and end-users.

In conclusion, nail dies play a vital role in the production of high-quality nails, offering a range of benefits that contribute to the efficiency and effectiveness of nail making machines. From ensuring consistency and uniformity to increasing production speed and versatility, nail dies are an essential component of nail manufacturing. By investing in quality nail dies, manufacturers can improve the quality of their products, streamline their production processes, and meet the demands of a competitive market.