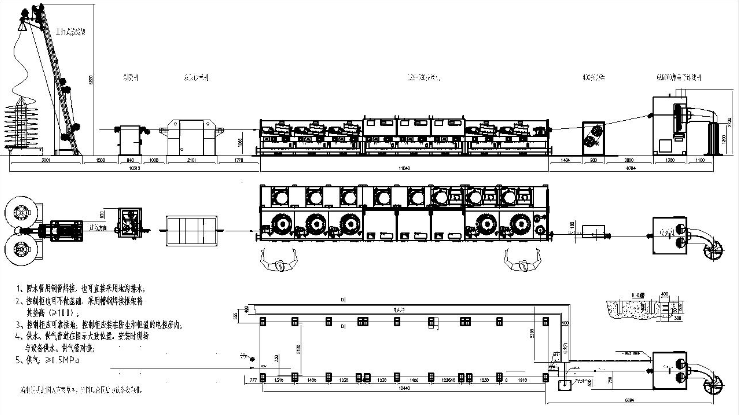

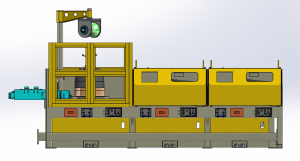

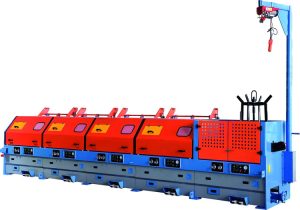

Straight line wire drawing machine,Dry Type Wire Drawing Machine,Continuous Wire Drawing Machine,

- It is suitable for all kinds of metal.

- Cooling system : internal Drum and Die Box, both have the cooling system.

- Drum : after multiple materials treatment and processing, the surface of Drum has the mirror treatment, and it can efficiently prevent wire surface scratch. It is durable, and a long life as well.

- Human-Machine Interface Digital Control System & Industry 4.0 :

- Electric control system provides a smooth acceleration from zero to the pre-selected value. Monitoring at office with MIS system by connecting the networks. It also could be monitored by the smart phone. Remote connection through modem allows On-line trouble shooting by Engineers.

- Gear Box : gears are suitable for long time operating with high load.

straight line wire drawing machine,Dry Type Wire Drawing Machine,Continuous Wire Drawing Machine,

Wire drawing is a metalworking process used to reduce the cross-section of a wire by pulling the wire through a single, or series of, drawing die(s).

The machine frame:

The capstan of wire drawing machine:

The first OTO type wire drawing block

This model in the first two positions give the opportunity to work through an inlet wire snarl while allowing the finishing end of the machine to continue running. Additionally, when there is a snarl, the electrical program can be set to stop the #1 block as quickly as possible without concern for wire breaks. This can mean the difference between an easy to resolve loop or a tightly kinked knot in the rod. Wire twist imparted by the OTO block does not present a problem in most cases. The first capstan can be tilted and a limited-stroke dancer provided to allow the option of stringing-up as a straight-line capstan or OTO as desired.

The riding wire stripper design for the last block

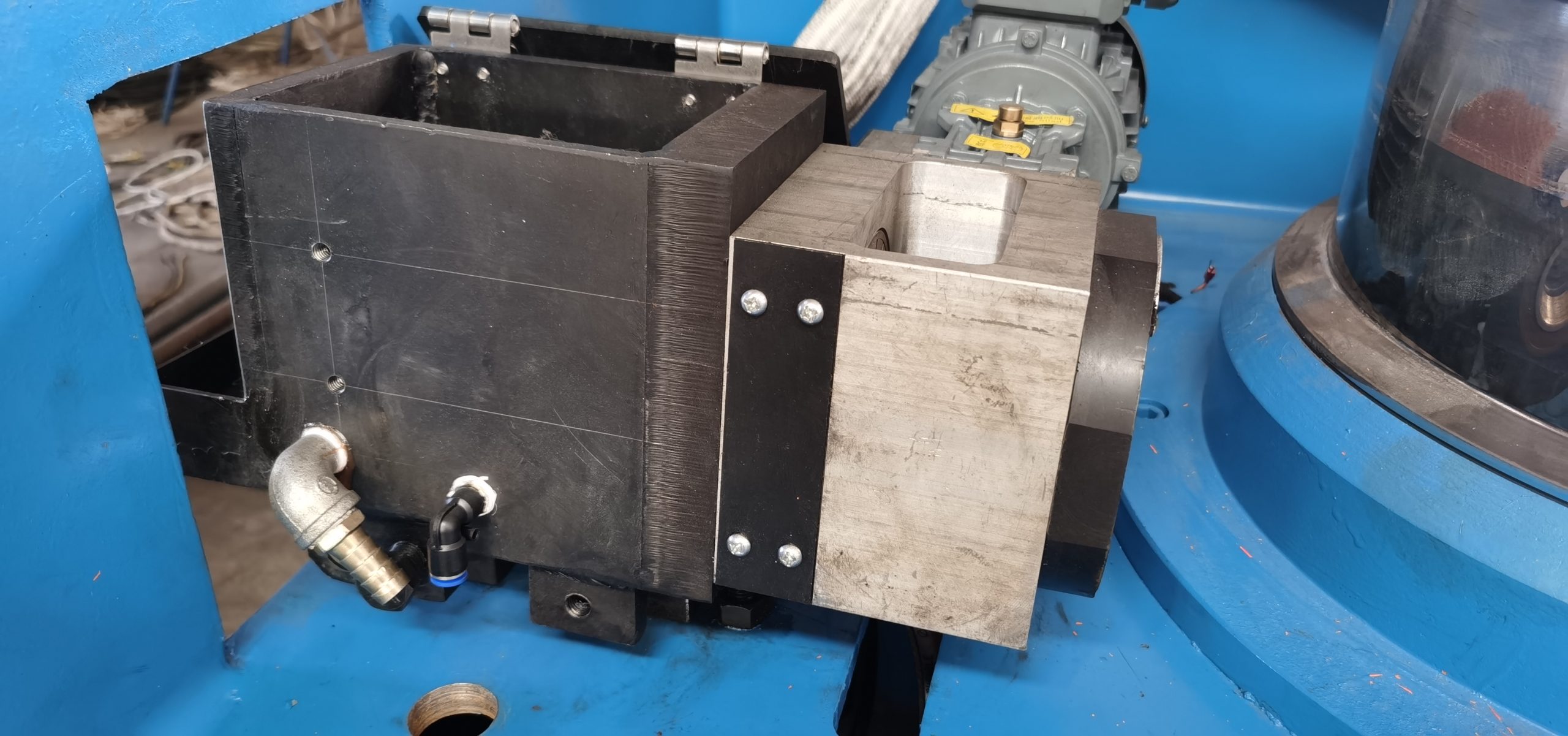

The die holder(box), the die boxes,the soap boxes for the wire drawing machine

The first die holder with force pressed soap powder

The Rotating Die Holders with direct or indirect water-cooling to provide consistent die wear, thereby improving die life

A mechanical soap stirring system providing adjustable agitation of drawing lubricant to prevent tunneling in the powdered soap

The Roller Cassette for the Wire Drawing Process.

The roller cassette is new technolgy for the wire drawing process, the roller casstte be lubricant by oil or water, it can help the final user save the electric energy and soap powder consumption.

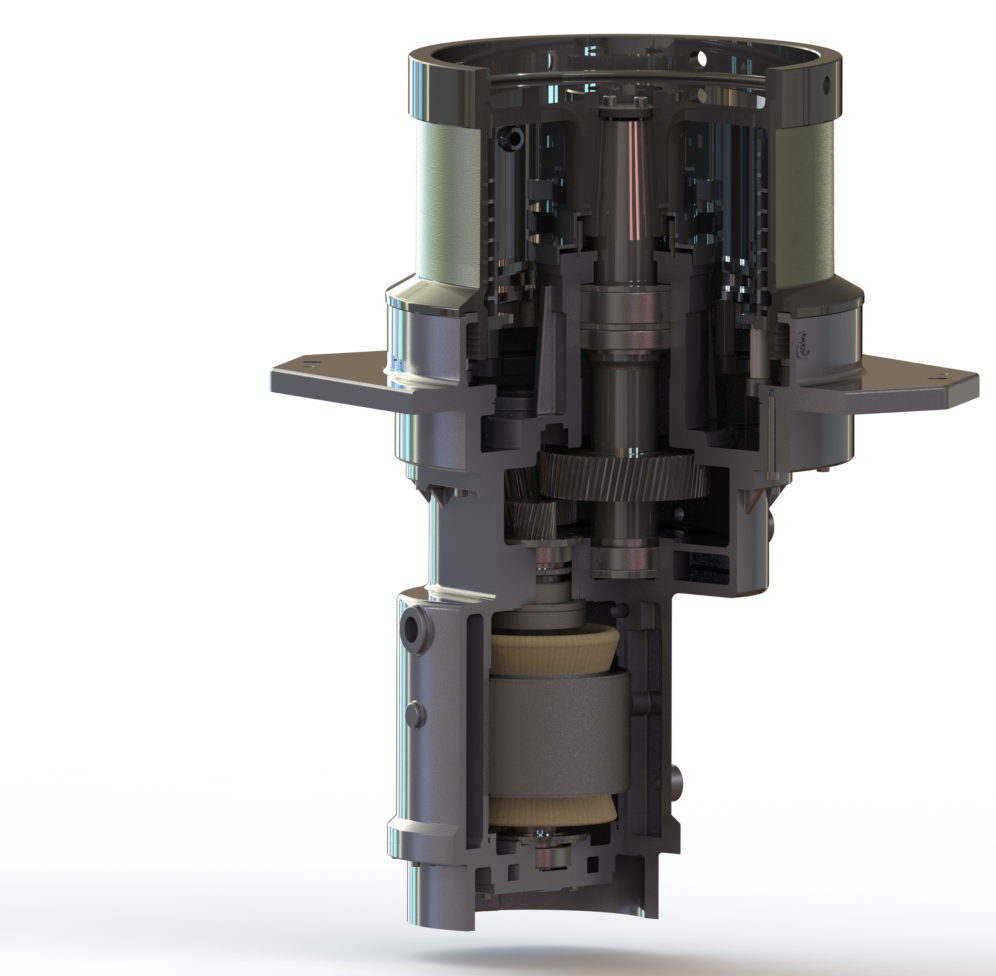

The machine transimission system

The gear reducer drive

Servo motor with gear reducer drive

The machine tension arm

The anti-shake device

The de-grease device after wire drawing machne

The take-up machine for the wire drawing machine

The horizental spoolers

The Electrical control system

Profibus field bus control system, touching screen show, human-computer communication, long-distance diagnose function.

Slowdown to stop at fixed length automatically, wire broken test and stop work automatically, cut off any block to compose new technical process freely,slowdown to stop automatically when the protecting shield is open, show of all kinds of fault information and the solution, inspection and control of all kinds of running information.