-

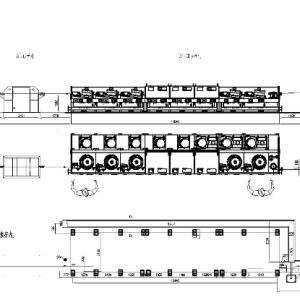

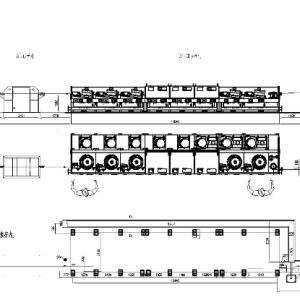

The production line is for the production of CO2 welding wire, from diameter 5.5mm or 6.5mm to finished wire diameter 0.8mm, 1.0mm, 1.2mm or 1.6mm by one-step production with high speed copper coating with speed of 25-30 meters per second.

it includes pay-off, descaler, belt grinding machine, wire drawing line, wire cleaning line, copper coating line, skin pass and take-up.

the total length of the production line be 65 meters.

-

The CO2 gas welding process route:

1 raw materials (Ф5.5 mm or Ф6.5 mm )→ steel pretreatment (including pay-off stand + machine shell+water cleaning + electrolytic pickling + high-frequency drying + cold wind dried) →LZ7/560 straight line drawing machine→SG800 h-wheel take-up machines

2 FX800 h-wheel pay-off machines→LZ8/400(or LZ7/400 or LZ6/400) straight line drawing machine →tension frame →cleaning trough→SG630 h-wheel take-up machines

3 FX630 pay-off machine→self-adjust tensile pay-off stand→steel roller bogie→hot scrub→electrolysis alkali bath→neutralization after alkali→electrolytic pickling tank→cleaning and activation tank→chemical coating bath→water wash neutralization→hot water washing electrical heating drying→bogie→tractor →SG630 H-Wheel take-up machine

4 SG630 h-wheel pay-off machine→ tensile rack→wire winding(into each coil to 15Kg or 20Kg)

5 BS4525 heat shrinkable packer for packaging, storage

-

The spooler is for taking up various metal wires from drawing machine.

-

Wire Pre-treatment: Used to remove mill scale and surface oxidation

Rugged welded construction.

Descaling by means of breaking and bending rollers.

Wire working ranges up to 16mm

Supplied with 3 or 5 orthogonal bending rollers

Tungsten carbide roll inserts

Adjustable straightener (SDC-10T)

Motorized bending roller adjustment (SDC-12AGF/16AGF)

Straight pass through wire rod threading for ease of stringing (SDC-12AGF/16AGF)

-

For cleaning sanding or removing surface defects by means of 2 sanding belts as well as optionally by means of a pressing device

30% more sanding surface than commercially available allows for particularly long sanding belt life and best productivity Suitable for any wire quality

Flyer and both sand belt speeds independent and seperate adjustable

Sand Belt Grinding Descaler,Belt Descaler,Wire Descaling Machine Manufacturer,China Factory,

-

- It is suitable for all kinds of metal.

- Cooling system : internal Drum and Die Box, both have the cooling system.

- Drum : after multiple materials treatment and processing, the surface of Drum has the mirror treatment, and it can efficiently prevent wire surface scratch. It is durable, and a long life as well.

- Human-Machine Interface Digital Control System & Industry 4.0 :

- Electric control system provides a smooth acceleration from zero to the pre-selected value. Monitoring at office with MIS system by connecting the networks. It also could be monitored by the smart phone. Remote connection through modem allows On-line trouble shooting by Engineers.

- Gear Box : gears are suitable for long time operating with high load.