Exploring The Benefits of Using wire flattening machines in Manufacturing Operations

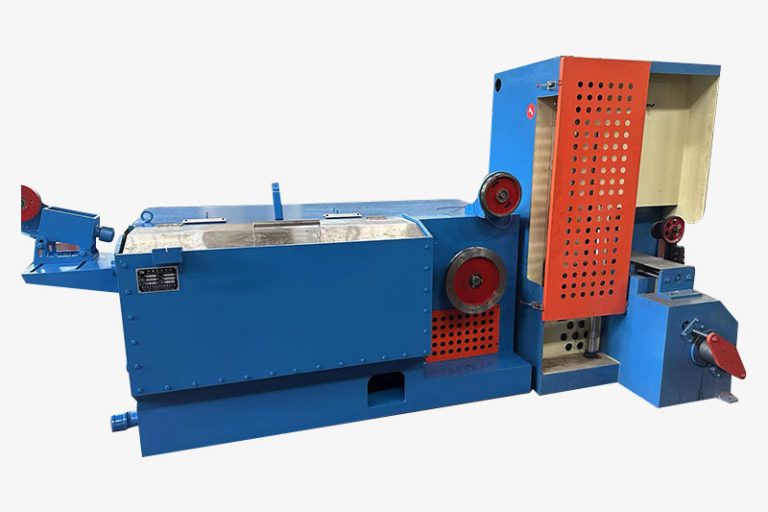

Wire flattening machines are a crucial tool in the manufacturing industry, offering a wide range of benefits that can significantly improve efficiency and productivity. These machines are designed to flatten wire, rods, and other materials to precise dimensions, making them ideal for a variety of applications in industries such as automotive, construction, and electronics.

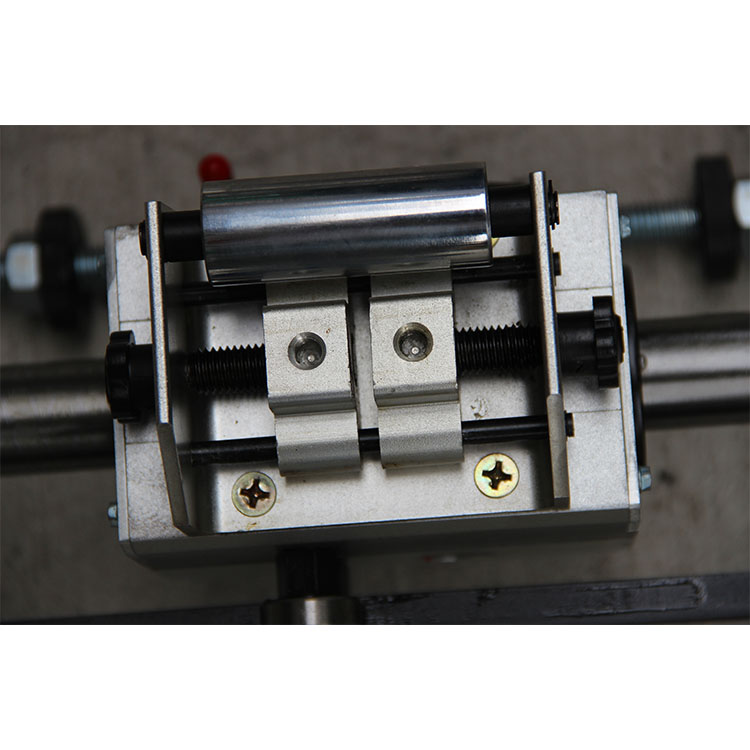

One of the key benefits of using wire flattening machine for staple nail is their ability to produce consistent and uniform results. By flattening wire to precise dimensions, these machines ensure that each piece meets the required specifications, reducing the risk of errors and inconsistencies in the manufacturing process. This level of precision is essential for industries that require high-quality products with tight tolerances.

In addition to producing consistent results, wire flattening machines also offer increased efficiency in the manufacturing process. These machines are capable of flattening wire at high speeds, allowing manufacturers to produce large quantities of flattened wire in a short amount of time. This can help to reduce production times and increase overall output, leading to cost savings and improved profitability for businesses.

Another benefit of using wire flattening machines is their versatility. These machines can be used to flatten a wide range of materials, including steel, aluminum, and copper, making them suitable for a variety of applications. Whether manufacturers are producing wire for automotive components, construction materials, or electronic devices, wire flattening machines can help to meet their specific needs.

Furthermore, wire flattening machines are easy to operate and maintain, making them a valuable asset for manufacturing operations. These machines are designed to be user-friendly, with intuitive controls and settings that allow operators to quickly set up and run the machine. Additionally, wire flattening machines are built to withstand the rigors of industrial use, requiring minimal maintenance to keep them running smoothly.

Overall, the benefits of using wire flattening machines in manufacturing operations are clear. From producing consistent and uniform results to increasing efficiency and versatility, these machines offer a range of advantages that can help businesses improve their production processes and achieve greater success. By investing in a wire flattening machine, manufacturers can streamline their operations, reduce costs, and deliver high-quality products to their customers.