Table of Contents

Consejos para el mantenimiento adecuado de la máquina rectificadora de banda lijadora

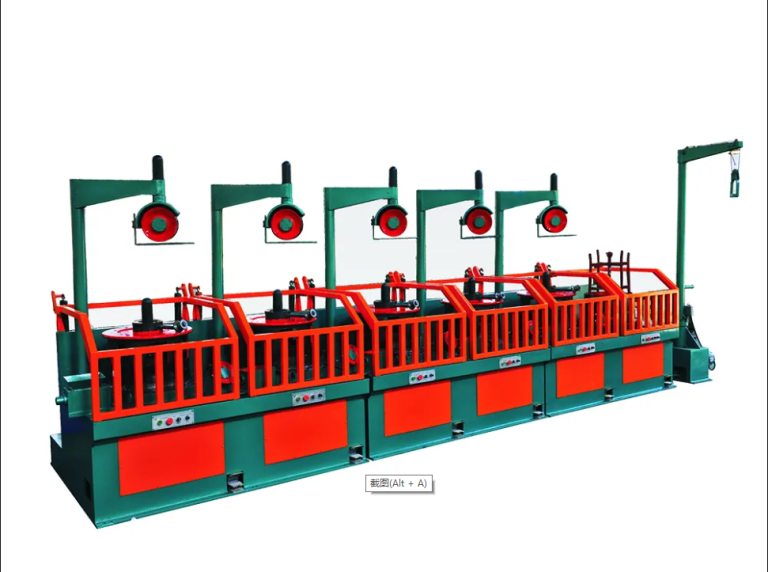

La máquina de cinta lijadora es una herramienta esencial en diversas industrias para terminar y dar forma a metal, madera y otros materiales. Para garantizar la longevidad y eficiencia de estas máquinas, el mantenimiento adecuado es fundamental. Descuidar el mantenimiento puede provocar una disminución del rendimiento, un mayor desgaste y, en última instancia, reparaciones o reemplazos costosos. En este artículo, discutiremos algunos consejos para el mantenimiento adecuado de las rectificadoras de banda de lijado.

En primer lugar, es importante inspeccionar periódicamente la máquina para detectar signos de desgaste o daños. Revise las bandas de lijado en busca de roturas, deshilachados o desgaste desigual. Reemplace cualquier correa dañada inmediatamente para evitar daños mayores a la máquina o la pieza de trabajo. Inspeccione los componentes de la máquina, como el motor, los cojinetes y las poleas, en busca de signos de desgaste o mal funcionamiento. Aborde cualquier problema con prontitud para evitar problemas más graves en el futuro.

Otro aspecto importante del mantenimiento es mantener la máquina limpia. El polvo y los residuos pueden acumularse en los componentes de la máquina, lo que provoca una disminución del rendimiento y posibles daños. Limpie periódicamente la máquina con una aspiradora o aire comprimido para eliminar cualquier acumulación. Preste especial atención a las bandas de lijado, ya que los residuos atrapados en ellas pueden provocar un desgaste desigual y un rendimiento deficiente. Además, limpie el área de trabajo de la máquina para evitar que entre polvo y residuos en la máquina.

La tensión adecuada de la máquina de cinta lijadora desincrustadora mecánica también es crucial para el rendimiento de la máquina. Las correas demasiado tensas pueden provocar un desgaste excesivo de los componentes de la máquina, mientras que las correas poco tensadas pueden provocar un rendimiento deficiente y un lijado desigual. Siga las pautas del fabricante para tensar las correas y verifique y ajuste periódicamente la tensión según sea necesario. Las correas correctamente tensadas garantizarán un funcionamiento suave y un rendimiento óptimo de la máquina.

Lubricar periódicamente las piezas móviles de la máquina es otra tarea de mantenimiento importante. La lubricación ayuda a reducir la fricción y el desgaste de los componentes de la máquina, prolongando su vida útil. Utilice el lubricante adecuado para cada componente, como aceite para rodamientos y grasa para engranajes. Siga las recomendaciones del fabricante en cuanto a intervalos y cantidades de lubricación para garantizar un mantenimiento adecuado de la máquina.

Además de las tareas de mantenimiento regulares, es importante programar inspecciones y ajustes periódicos de la máquina. Los técnicos de mantenimiento profesionales pueden identificar y abordar cualquier problema potencial antes de que se convierta en un problema grave. Las puestas a punto periódicas también pueden ayudar a optimizar el rendimiento y la eficiencia de la máquina, garantizando que funcione de la mejor manera.

Si sigue estos consejos para el mantenimiento adecuado de las rectificadoras de banda de lijado, puede prolongar su vida útil, mejorar su rendimiento y evitar costosas reparaciones o reemplazos. Las inspecciones periódicas, la limpieza, el tensado, la lubricación y los ajustes son esenciales para mantener estas máquinas en las mejores condiciones. Un mantenimiento adecuado no sólo beneficia a la máquina sino que también garantiza resultados de alta calidad en sus piezas de trabajo. Invierta tiempo y esfuerzo en el mantenimiento de su máquina rectificadora de banda de lijado y obtendrá los frutos de un mejor rendimiento y longevidad.

Beneficios de utilizar una máquina rectificadora de banda lijadora para la fabricación de metales

La fabricación de metales es un proceso complejo que implica dar forma y manipular materiales metálicos para crear diversos productos. Una herramienta esencial en la fabricación de metales son las máquinas de cinta lijadora. Esta máquina se utiliza para eliminar el exceso de material, alisar superficies y dar forma a piezas de metal según las especificaciones deseadas. En este artículo, exploraremos los beneficios de utilizar una máquina rectificadora de cinta lijadora en la fabricación de metales.

Una de las principales ventajas de utilizar una máquina rectificadora de cinta lijadora es su eficiencia. Esta máquina está diseñada para eliminar material de superficies metálicas de forma rápida y precisa, ahorrando tiempo y mano de obra en el proceso de fabricación. La banda abrasiva de la máquina se puede reemplazar fácilmente cuando está desgastada, lo que garantiza un rendimiento constante y una alta productividad.

Además, la máquina rectificadora de banda de lijado proporciona un alto nivel de precisión en la fabricación de metales. La máquina permite un control preciso sobre la cantidad de material eliminado, lo que da como resultado superficies lisas y uniformes en piezas metálicas. Este nivel de precisión es esencial para crear productos de alta calidad que cumplan con las especificaciones exactas del diseño.

Además, la máquina rectificadora de banda lijadora es versátil y se puede utilizar para una amplia gama de tareas de fabricación de metales. Ya sea que necesite eliminar rebabas, pulir superficies o dar forma a piezas de metal, esta máquina puede manejarlo todo. Sus ajustes de velocidad y presión ajustables permiten la personalización según los requisitos específicos de cada proyecto.

Otro beneficio de utilizar una máquina rectificadora de banda de lijado es su rentabilidad. Al invertir en esta máquina, los fabricantes de metales pueden ahorrar dinero en costos laborales y aumentar la productividad en sus operaciones. La durabilidad y la larga vida útil de la máquina también contribuyen a su rentabilidad, lo que la convierte en un activo valioso para cualquier taller de fabricación de metales.

Además de su eficiencia y precisión, la máquina rectificadora de banda de lijado también ofrece mayor seguridad en la fabricación de metales. La máquina está equipada con elementos de seguridad, como protectores y botones de parada de emergencia, para proteger a los operadores de accidentes y lesiones. Esto garantiza un entorno de trabajo seguro para los fabricantes de metales y reduce el riesgo de incidentes en el lugar de trabajo.

Además, la máquina rectificadora de cinta lijadora es fácil de operar y mantener, lo que la convierte en una herramienta fácil de usar para fabricantes de metales de todos los niveles. Con la capacitación adecuada y un mantenimiento regular, esta máquina puede proporcionar un rendimiento constante y resultados confiables en proyectos de fabricación de metal.

En general, los beneficios de utilizar una máquina rectificadora de banda lijadora en la fabricación de metal son numerosos. Desde su eficiencia y precisión hasta su versatilidad y rentabilidad, esta máquina es un activo valioso para cualquier taller de fabricación de metales. Al invertir en una máquina rectificadora de cinta lijadora, los fabricantes de metales pueden mejorar la productividad, mejorar la calidad y garantizar la seguridad en sus operaciones.