Table of Contents

Advantages of Using Rolling Ring Linear Drives in Industrial Automation

Rolling Ring Drive is a type of linear motion system that is commonly used in industrial automation applications. These drives offer a number of advantages over other types of linear motion systems, making them a popular choice for many industrial automation tasks.

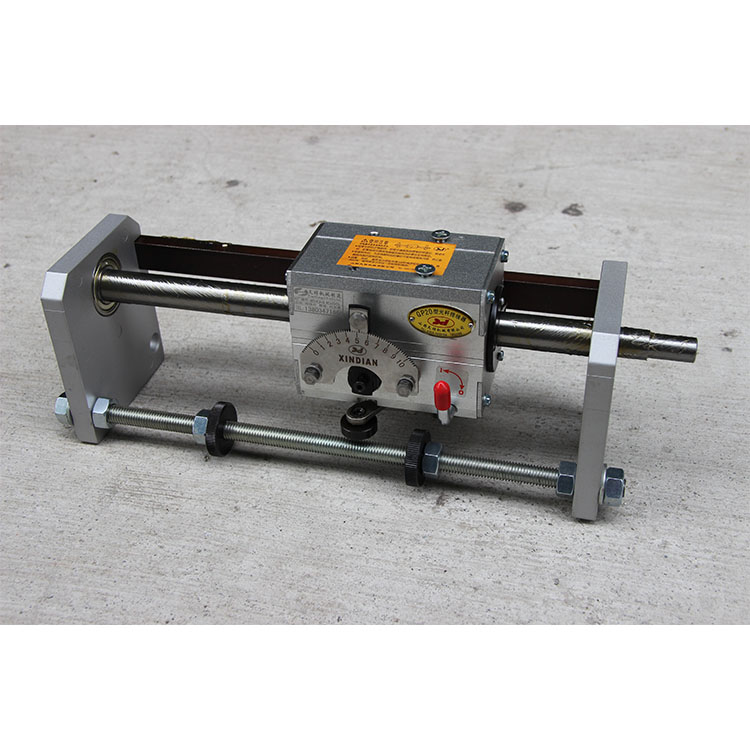

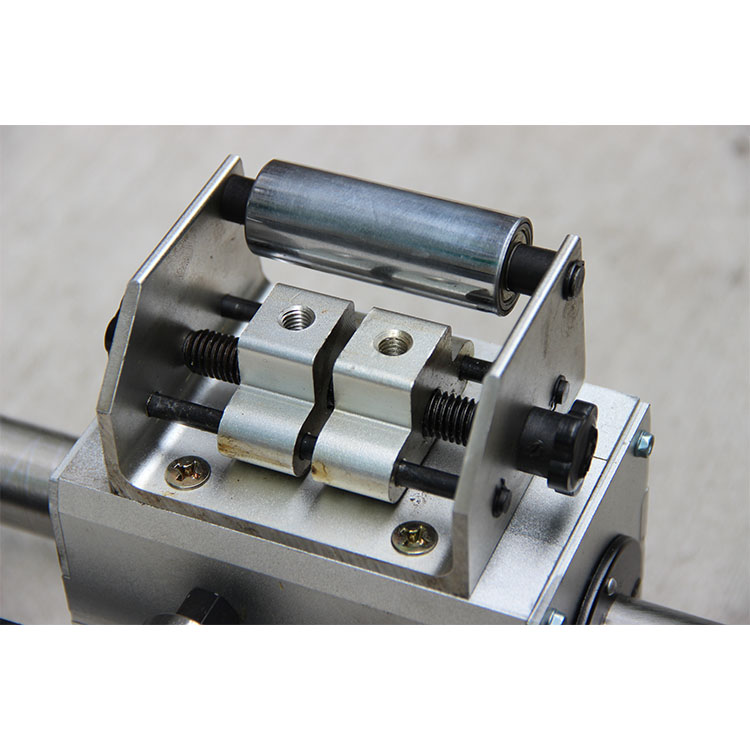

One of the key advantages of rolling ring linear drives is their simplicity. These drives consist of just a few basic components, including a rolling ring, a nut, and a shaft. This simplicity makes them easy to install and maintain, reducing downtime and increasing productivity in industrial automation applications.

Another advantage of rolling ring linear drives is their high precision. These drives are capable of achieving very precise positioning, making them ideal for applications that require accurate and repeatable motion control. This precision is essential in many industrial automation tasks, such as assembly, testing, and inspection.

Rolling ring linear drives also offer high speed capabilities. These drives are capable of moving at high speeds, making them suitable for applications that require fast and efficient motion control. This high speed capability can help to increase throughput and efficiency in industrial automation processes.

In addition to their speed and precision, rolling ring linear drives are also known for their durability. These drives are designed to withstand the rigors of industrial environments, including exposure to dust, dirt, and other contaminants. This durability helps to ensure that rolling ring linear drives will continue to perform reliably over time, even in harsh operating conditions.

Another advantage of rolling ring linear drives is their versatility. These drives can be easily customized to meet the specific requirements of a wide range of industrial automation applications. This versatility makes rolling ring linear drives a flexible and adaptable choice for many different types of tasks.

Rolling ring linear drives are also known for their smooth and quiet operation. These drives produce minimal noise and vibration, creating a more comfortable working environment for operators. This smooth operation can also help to extend the life of the drive system and reduce maintenance requirements.

Overall, rolling ring linear drives offer a number of advantages that make them a popular choice for industrial automation applications. Their simplicity, precision, speed, durability, versatility, and smooth operation all contribute to their effectiveness in a wide range of tasks. Whether used for assembly, testing, inspection, or other automation tasks, rolling ring linear drives are a reliable and efficient choice for many industrial applications.

How to Select the Right Rolling Ring Linear Drive for Your Application

Rolling ring linear drives are a type of linear motion system that is commonly used in various industrial applications. These drives are known for their simplicity, reliability, and precision, making them a popular choice for many engineers and designers. However, with so many options available on the market, selecting the right rolling ring linear drive for your specific application can be a daunting task. In this article, we will discuss some key factors to consider when choosing a rolling ring linear drive to ensure optimal performance and efficiency.

One of the first things to consider when selecting a Rolling Ring Traverse Drive is the load capacity. It is important to determine the maximum load that the drive will need to handle in order to select a drive that can provide the necessary force. Additionally, it is important to consider the speed requirements of the application. Different rolling ring linear drives have different speed capabilities, so it is important to choose a drive that can meet the speed requirements of your specific application.

Another important factor to consider when selecting a rolling ring linear drive is the stroke length. The stroke length refers to the distance that the drive can travel in a single motion. It is important to choose a drive with a stroke length that is suitable for the specific requirements of your application. Additionally, it is important to consider the accuracy requirements of the application. Some rolling ring linear drives offer higher levels of precision than others, so it is important to choose a drive that can provide the necessary level of accuracy for your specific application.

In addition to load capacity, speed, stroke length, and accuracy, it is also important to consider the environmental conditions in which the rolling ring linear drive will be operating. Some drives are better suited for harsh environments, such as those with high temperatures or exposure to chemicals, while others may be more suitable for clean room environments. It is important to choose a drive that is designed to withstand the specific environmental conditions of your application in order to ensure long-term reliability and performance.

When selecting a rolling ring linear drive, it is also important to consider the overall system design. It is important to choose a drive that is compatible with the other components of the system, such as motors, controllers, and feedback devices. Additionally, it is important to consider the overall size and weight of the drive, as well as any mounting requirements. By considering these factors, you can ensure that the rolling ring linear drive will integrate seamlessly into your overall system design.

In conclusion, selecting the right rolling ring linear drive for your application requires careful consideration of a variety of factors, including load capacity, speed, stroke length, accuracy, environmental conditions, and system design. By taking the time to carefully evaluate these factors, you can choose a drive that will provide optimal performance and efficiency for your specific application.