The Benefits of Using Tungsten Carbide Nail Making Die For Enkotec Nail Making Machine

Nail making machines have revolutionized the nail manufacturing industry by increasing efficiency and productivity. One of the key components of these machines is the nail making die, which plays a crucial role in shaping the nails.Tungsten Carbide Nail Making Machine Tools have become increasingly popular due to their durability and efficiency. In this article, we will explore the benefits of using tungsten carbide nail making dies for Enkotec nail making machines.

Tungsten carbide is a versatile material known for its hardness and resistance to wear and corrosion. These properties make it an ideal choice for nail making dies, which are subjected to high levels of stress and wear during the manufacturing process. Enkotec Tungsten carbide nail making dies can withstand the repetitive impact and pressure of the nail making machine, resulting in longer tool life and reduced downtime for maintenance and replacement.

One of the key benefits of using ENKOTEC Nail Making Machine Tools is their superior wear resistance. Tungsten carbide is much harder than steel, which means that it can maintain its shape and sharpness for a longer period of time. This results in consistent nail quality and reduced scrap rates, ultimately leading to cost savings for nail manufacturers. Additionally, the high wear resistance of tungsten carbide nail making dies reduces the need for frequent sharpening or replacement, further increasing productivity and efficiency.

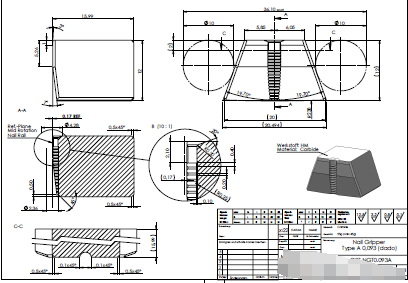

Another advantage of Nail Gripper,Nail Die,Nail Mould, is their excellent thermal conductivity. This property allows for efficient heat dissipation during the nail making process, preventing overheating and ensuring consistent nail production. The thermal stability of tungsten carbide also helps to minimize thermal expansion and contraction, which can lead to dimensional inaccuracies in the nails. As a result, tungsten carbide nail making dies can produce nails with precise dimensions and high quality.

In addition to their wear resistance and thermal conductivity, tungsten carbide nail making tools offer superior corrosion resistance. This is particularly important in the nail manufacturing industry, where exposure to moisture and chemicals can lead to rust and degradation of the tooling. Tungsten carbide is highly resistant to corrosion, ensuring that the nail making dies remain in optimal condition for extended periods of time. This not only prolongs the life of the tooling but also maintains the quality of the nails produced.

Overall, the benefits of using nail making dies for Enkotec nail making machines are clear. From their superior wear resistance and thermal conductivity to their excellent corrosion resistance, tungsten carbide nail making dies offer a range of advantages that can improve productivity, efficiency, and quality in nail manufacturing. By investing in high-quality tungsten carbide nail making dies, nail manufacturers can optimize their production processes and achieve consistent, high-quality nails.