Table of Contents

Maintenance Tips for Nail Dies in Nail Making Machines

Nail dies are an essential component of nail making machines, responsible for shaping and cutting the nails to the desired size and shape. Proper maintenance of nail dies is crucial to ensure the efficient operation of the nail making machine and the production of high-quality nails. In this article, we will discuss some maintenance tips for nail dies in nail making machines.

One of the most important maintenance tasks for nail dies is regular cleaning. Over time, nail dies can accumulate dirt, debris, and rust, which can affect the quality of the nails produced. To clean nail dies, it is recommended to use a soft brush or cloth to remove any dirt or debris. For stubborn dirt or rust, a mild solvent or cleaning solution can be used. It is important to thoroughly dry the nail dies after cleaning to prevent rusting.

In addition to cleaning, it is also important to inspect nail dies regularly for any signs of wear or damage. Inspecting nail dies can help identify any issues early on and prevent them from causing more significant problems down the line. If any wear or damage is detected, it is essential to address it promptly to ensure the continued operation of the nail making machine.

Another crucial maintenance tip for nail dies is proper lubrication. Lubricating nail dies helps reduce friction and wear, prolonging their lifespan and ensuring smooth operation. It is recommended to use a high-quality lubricant specifically designed for nail dies. When lubricating nail dies, it is important to apply the lubricant evenly and in the correct amount to prevent excess buildup, which can affect the quality of the nails produced.

Furthermore, it is essential to store nail dies properly when not in use. Nail dies should be stored in a clean, dry, and temperature-controlled environment to prevent rusting and damage. It is also recommended to store nail dies in a protective case or container to prevent them from being damaged or lost.

Lastly, it is crucial to follow the manufacturer’s guidelines for maintenance and care of nail dies. Each nail making machine may have specific requirements for the maintenance of nail dies, and it is essential to follow these guidelines to ensure the optimal performance of the machine and the production of high-quality nails.

In conclusion, proper maintenance of nail dies is essential for the efficient operation of nail making machines and the production of high-quality nails. Regular cleaning, inspection, lubrication, proper storage, and following manufacturer guidelines are all important aspects of maintaining nail dies. By following these maintenance tips, nail manufacturers can ensure the longevity and performance of their nail making machines and produce high-quality nails consistently.

How to Choose the Right Nail Die for Your Nail Making Machine

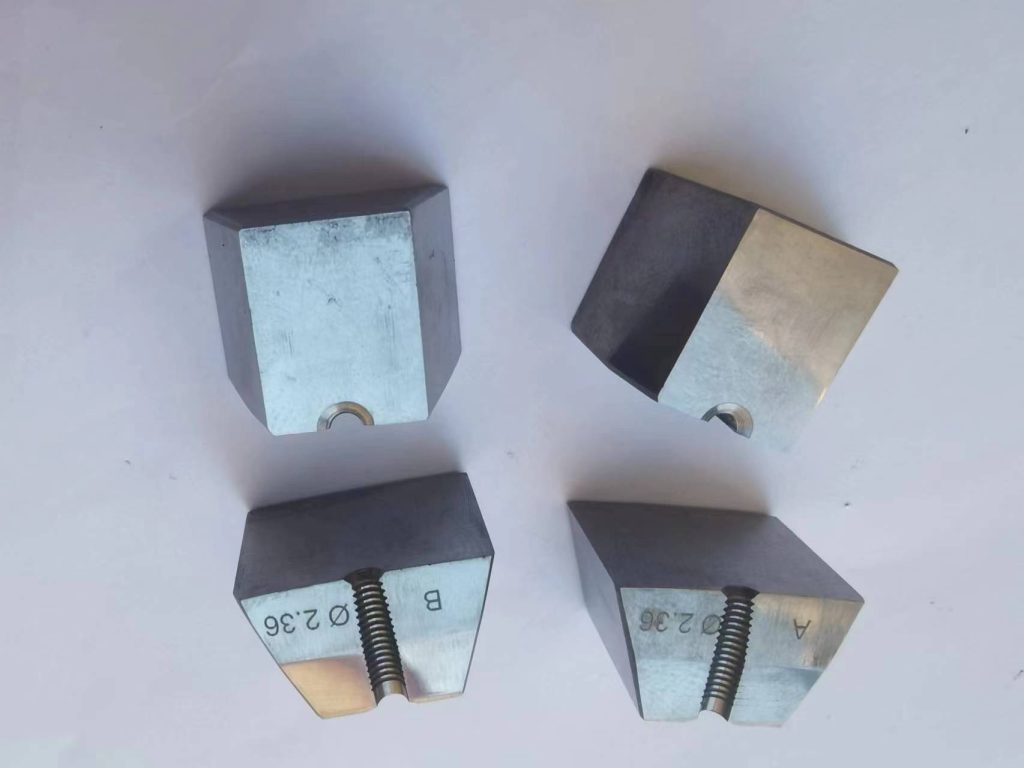

When it comes to nail making machines, one of the most crucial components is the nail die. The nail die is responsible for shaping the wire into the desired nail shape, and choosing the right nail die for your nail making machine is essential for producing high-quality nails efficiently. There are several factors to consider when selecting a Carrie Block For Enkotec Nail Making Machine, including the type of nails you want to produce, the material of the nail die, and the compatibility with your nail making machine.

First and foremost, you need to consider the type of nails you want to produce. Different nail dies are designed for specific nail shapes and sizes, so it’s important to choose a nail die that is suitable for the nails you want to manufacture. Whether you are producing common nails, roofing nails, or finishing nails, there is a nail die available to meet your needs. Make sure to carefully evaluate the specifications of each nail die to ensure it is compatible with the nails you want to produce.

Another important factor to consider when choosing a nail die is the material of the die. Nail dies are typically made from high-quality steel or carbide, with carbide being the more durable and long-lasting option. While steel nail dies are more affordable, they may wear out more quickly and require more frequent replacement. On the other hand, carbide nail dies are more expensive upfront but offer superior durability and longevity, making them a cost-effective choice in the long run. Consider your budget and production volume when deciding between steel and carbide nail dies.

Compatibility with your nail making machine is also a crucial consideration when selecting a nail die. Not all nail dies are compatible with all nail making machines, so it’s important to ensure that the nail die you choose is designed to work with your specific machine model. Check the specifications of both the nail die and your nail making machine to confirm compatibility before making a purchase. Using an incompatible nail die can result in poor nail quality, machine malfunctions, and costly repairs.

In addition to considering the type of nails, material, and compatibility, it’s also important to choose a reputable manufacturer when purchasing a nail die for your nail making machine. Look for manufacturers with a proven track record of producing high-quality nail dies that are reliable and durable. Reading customer reviews and testimonials can help you gauge the quality of a manufacturer’s products and customer service. Investing in a nail die from a reputable manufacturer will ensure that you receive a high-quality product that meets your production needs.

In conclusion, choosing the right nail die for your nail making machine is essential for producing high-quality nails efficiently. Consider the type of nails you want to produce, the material of the nail die, compatibility with your machine, and the reputation of the manufacturer when selecting a nail die. By carefully evaluating these factors, you can ensure that you choose a nail die that meets your production requirements and delivers consistent, reliable results.