Table of Contents

Advantages of Using Rotating Die Holders for Drawing Machines

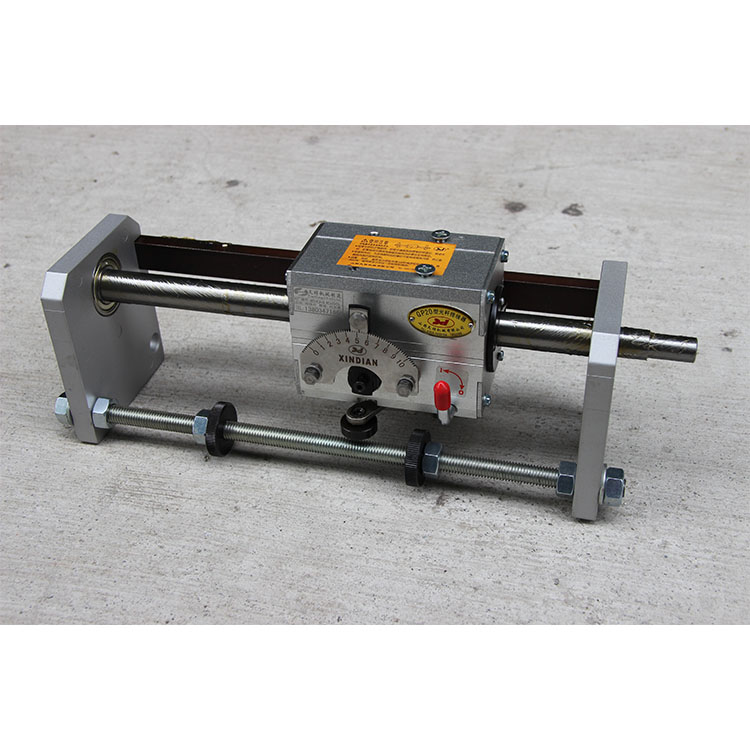

Rotating die holders are an essential component of drawing machines used in various industries such as metalworking, wire drawing, and tube drawing. These holders play a crucial role in the manufacturing process by securely holding the die in place while allowing it to rotate freely during the drawing operation. This rotational movement offers several advantages that make it a preferred choice for many manufacturers.

One of the primary benefits of using rotating die holders is the ability to reduce friction between the die and the workpiece. As the die rotates, it distributes the wear evenly across its surface, preventing localized wear that can lead to premature failure. This not only extends the lifespan of the die but also improves the quality of the finished product by ensuring consistent drawing performance.

In addition to reducing friction, Rotating Die Box also help to improve the overall efficiency of the drawing process. By allowing the die to rotate freely, manufacturers can achieve higher drawing speeds without compromising on quality. This increased productivity translates to lower production costs and faster turnaround times, making rotating die holders a cost-effective solution for manufacturers looking to optimize their operations.

Furthermore, rotating die holders offer greater flexibility in terms of die selection and setup. With a rotating holder, manufacturers can easily switch between different die sizes and configurations without the need for complex adjustments. This versatility allows for quick changeovers between production runs, reducing downtime and increasing overall throughput.

Another advantage of using rotating die holders is the ability to achieve more precise control over the drawing process. The rotational movement of the die allows for finer adjustments to be made to the drawing parameters, such as speed, tension, and lubrication. This level of control is essential for producing high-quality drawn products that meet the strict tolerances required by many industries.

Moreover, rotating die holders are designed to withstand the rigors of continuous operation in demanding manufacturing environments. Made from high-quality materials such as hardened steel or carbide, these holders are built to last and can withstand the high forces and temperatures generated during the drawing process. This durability ensures reliable performance and minimal maintenance requirements, further enhancing the overall efficiency of the manufacturing process.

In conclusion, rotating die holders offer a range of advantages that make them an indispensable tool for manufacturers using drawing machines. From reducing friction and improving efficiency to enhancing flexibility and control, these holders provide a cost-effective solution for optimizing the drawing process. With their durability and reliability, rotating die holders are a valuable investment for manufacturers looking to improve their production capabilities and deliver high-quality drawn products to their customers.

Tips for Choosing the Right Rotating Die Holder for Your Drawing Machine

Rotating die holders play a crucial role in the operation of drawing machines, which are used in various industries for shaping and forming metal wires, tubes, and other materials. These holders are designed to securely hold the die in place while allowing it to rotate freely during the drawing process. Choosing the right rotating die unit for your drawing machine is essential to ensure smooth and efficient operation. In this article, we will discuss some tips to help you select the best rotating die holder for your specific needs.

One of the most important factors to consider when choosing a rotating die holder is the material of construction. Die holders are typically made from materials such as steel, aluminum, or brass. Steel die holders are known for their durability and strength, making them ideal for heavy-duty applications. Aluminum die holders are lightweight and corrosion-resistant, making them suitable for applications where weight is a concern. Brass die holders are often used in applications where non-ferrous materials are being drawn.

Another important consideration when selecting a rotating die holder is the size and type of die that will be used. Die holders come in various sizes to accommodate different die diameters. It is essential to choose a die holder that is compatible with the size of the die you will be using to ensure a proper fit and secure hold. Additionally, the type of die, whether it is a round, square, or shaped die, will also impact the selection of the rotating die holder.

The design of the rotating die holder is another crucial factor to consider. Some die holders feature a quick-change design that allows for easy and efficient die changes, saving time and increasing productivity. Others may have adjustable features that allow for precise alignment and positioning of the die. It is essential to choose a die holder with a design that best suits your specific application requirements.

When selecting a rotating die holder, it is also important to consider the mounting options available. Die holders can be mounted in various ways, including on the drawing machine itself or on a separate stand. The mounting method will depend on the specific requirements of your application, such as space constraints or the need for flexibility in die positioning.

In addition to the material, size, type, design, and mounting options, it is essential to consider the quality and reputation of the manufacturer when choosing a rotating die holder. Working with a reputable manufacturer that has a track record of producing high-quality die holders will ensure that you are getting a reliable and durable product that meets your needs.

In conclusion, selecting the right rotating die holder for your drawing machine is essential to ensure smooth and efficient operation. Consider factors such as material, size, type, design, mounting options, and manufacturer reputation when making your decision. By following these tips, you can choose a rotating die holder that meets your specific application requirements and helps you achieve optimal results in your drawing operations.